Scale inhibition filtering assembly, evaporator and filtering control method applying scale inhibition filtering assembly and evaporator

A filter component and filter control technology, which is applied in the direction of chemical instruments and methods, applications, filter treatment, etc., can solve problems such as scale generation, and achieve the effects of prolonging service life, improving quality and user experience, and fully crystallizing and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

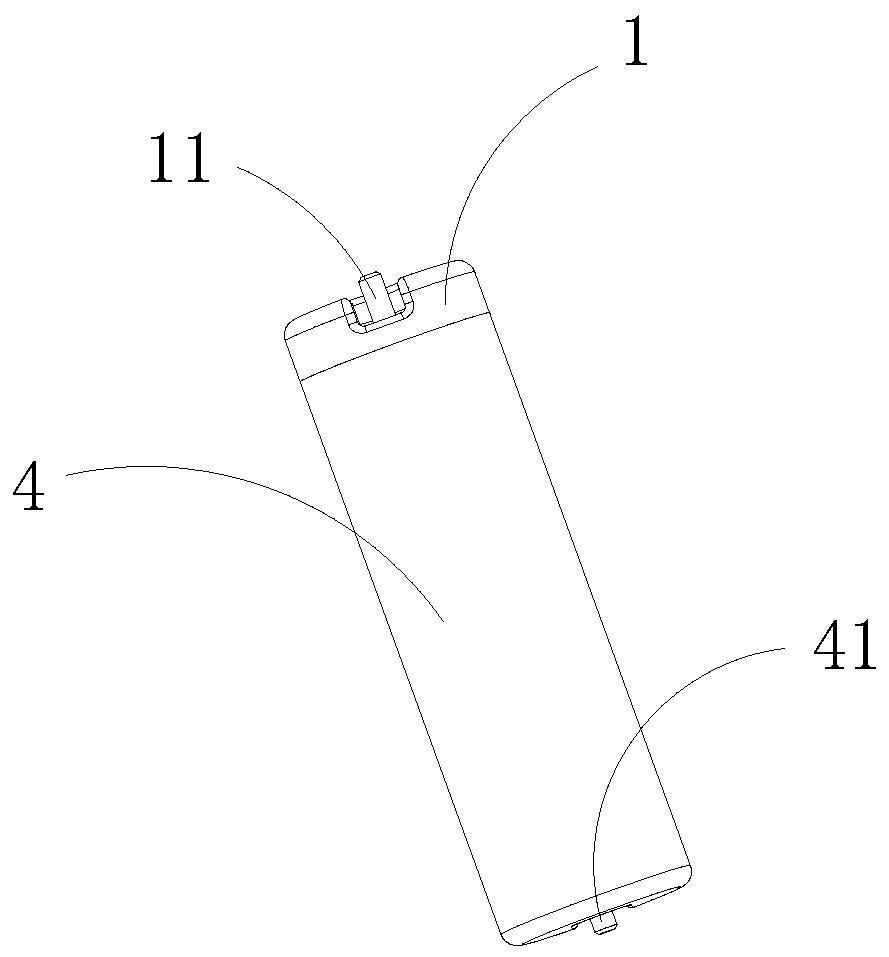

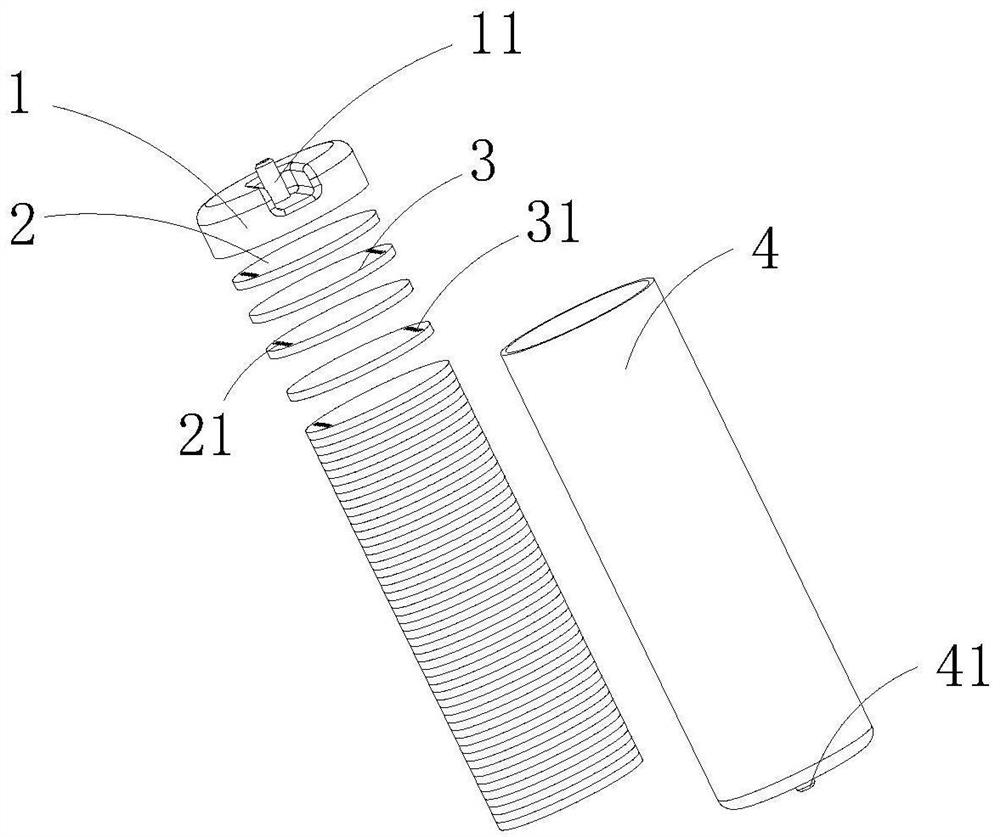

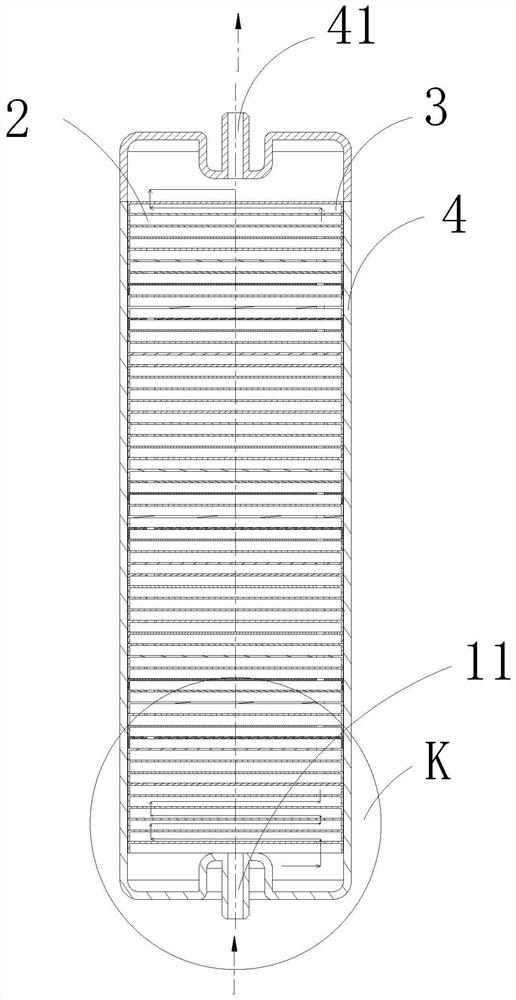

[0038] Embodiment 1 of the present invention provides a kind of anti-scaling filter assembly, such as figure 1 — Figure 7 Shown, a kind of antiscaling filtering assembly comprises antiscaling barrel 4, filter element, antiscaling water inlet pipe and antiscaling outlet pipe, and filter element is arranged in antiscaling barrel 4, and is coated with and is used for removing scale on the filter element The filter coating 22 is used to filter scale. One side of the anti-scale tank 4 is provided with an anti-scale water inlet pipe 41, and the other side is provided with an anti-scale end cap 1. The end cap 1 is provided with an anti-scale water outlet pipe 11. , used for water intake and anti-scaling water into the evaporator.

[0039] Preferably in the present invention, the filter element includes a first filter sheet 2 and a second filter sheet 3 for filtering scale.

[0040] Preferably in the present invention, there are at least two first filter sheets 2 and at least two s...

Embodiment 2

[0050] The second technical solution of the present invention is realized in the following way: an evaporator, used for steam cooking equipment, includes the above-mentioned anti-scaling filter assembly, the anti-scaling water inlet pipe 41 is connected with the water tank, and is used to supply water to the anti-scaling filter assembly, The anti-scaling outlet pipe 11 is connected with the water inlet end of the evaporator, and is used for delivering the filtered water to the evaporator.

[0051] After adopting the above scheme, by applying the antiscaling filter assembly described in Example 1 in the evaporator provided in Example 2, the generation of scale can be effectively prevented, thereby improving the quality of the steam cooking equipment using the evaporator and user experience, while also prolonging the service life of steam cooking equipment.

Embodiment 3

[0053] The 3rd technical scheme of the present invention is realized like this: Figure 8 with Figure 9 As shown, a filtering control method is used for steam cooking equipment, including the above-mentioned evaporator, and the filtering control method includes the following steps:

[0054] S1: The water level sensor of the water tank judges whether the water volume meets the water volume requirement of the current cooking recipe;

[0055] S2: When the water volume of the water tank meets the minimum water volume requirement, the evaporator program calculates the water supply time according to the water volume demand of the current cooking recipe, and controls the water pump connected to the water tank to pump the required water volume of the current cooking recipe ahead of the water supply time;

[0056] S3: The evaporator program controls the water supply pump connected to the anti-scale filter assembly to start working, and pumps water into the evaporator according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com