Multi-working-condition metal liquid drop ignition experiment device

A technology of metal droplets and experimental equipment, which is applied in the direction of chemical analysis by means of combustion, can solve the problems of unexperimental research, difficulty in controlling the amount of molten material, temperature, and speed, and achieve the effect of ensuring controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

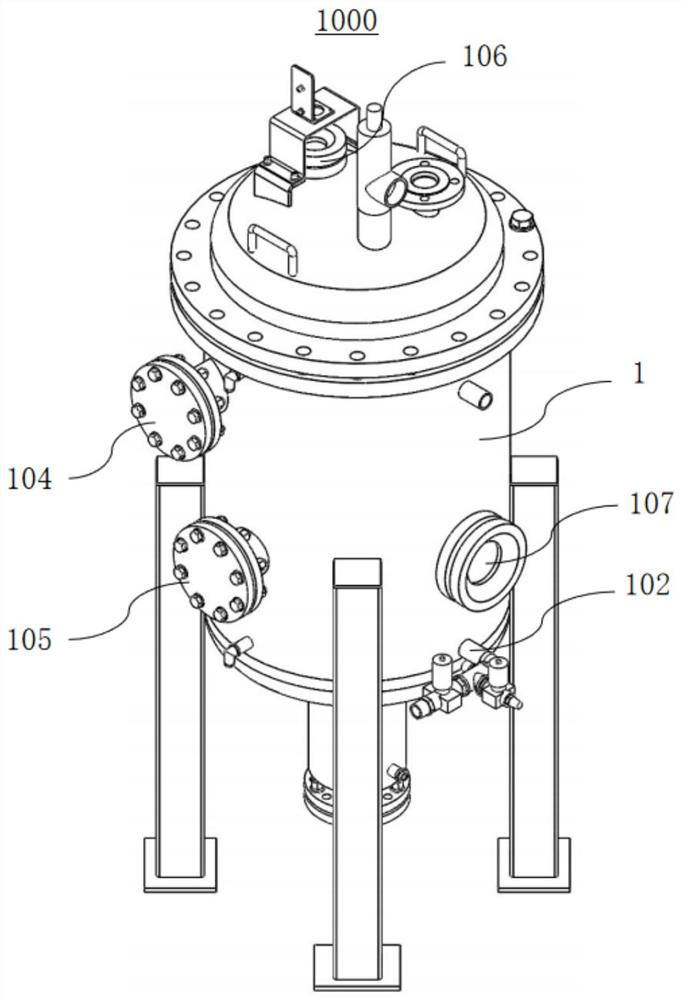

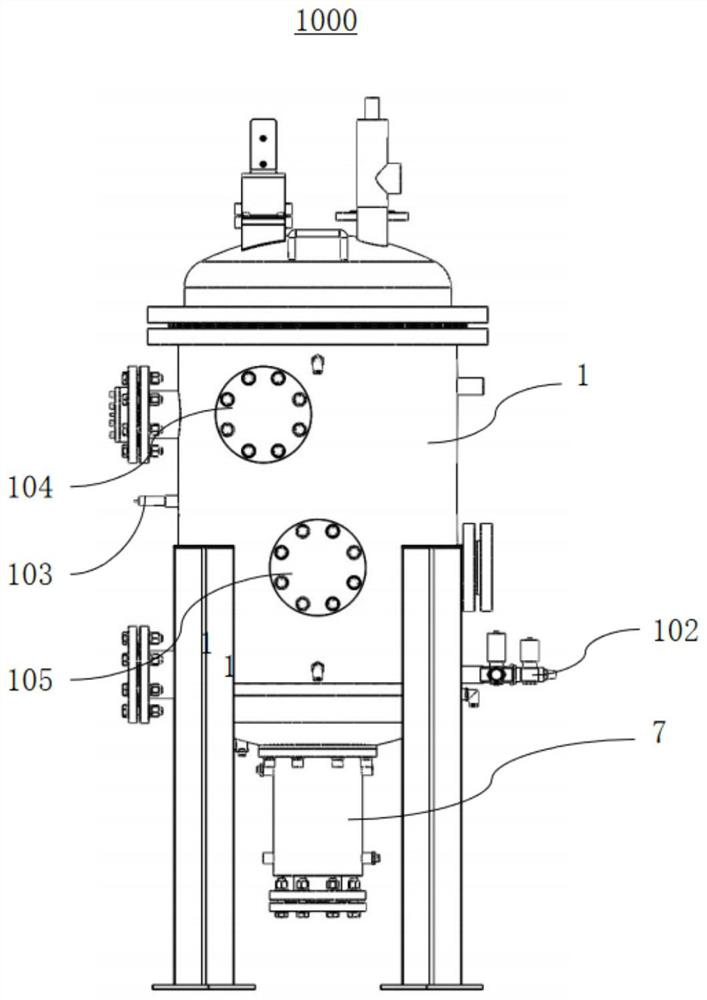

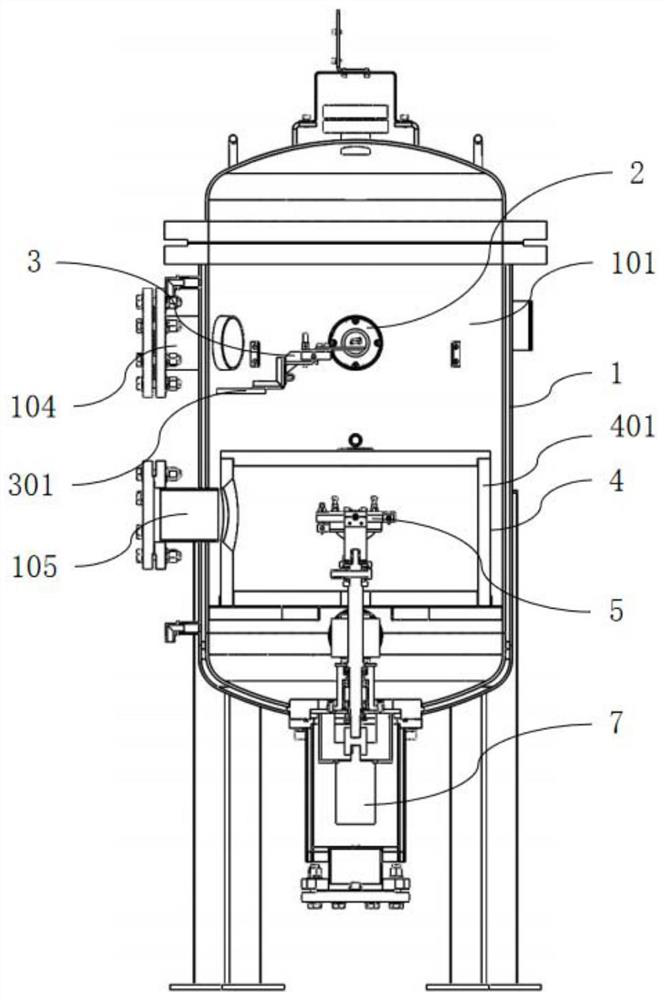

[0050] Combine below Figure 1 to Figure 6 The experimental device 1000 for ignition of metal droplets under multiple working conditions according to an embodiment of the present invention will be described.

[0051] The metal droplet ignition test device 1000 with multiple working conditions according to the embodiment of the present invention includes a high-pressure cabin 1 , a high-frequency electromagnetic heating furnace 2 , a sample filling assembly 3 , an incubator 4 , and a floor heating and insulation assembly 5 . A hyperbaric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com