Rolling bearing degradation index extraction method based on time-frequency feature separation

A rolling bearing, time-frequency characteristic technology, applied in the field of rolling bearing fault diagnosis, can solve problems such as inability to characterize bearing degradation process, impact component distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

[0063] Such as figure 1 As shown, a rolling bearing degradation trend acquisition method based on time-frequency characteristic analysis, using the original signal of the bearing outer ring fault in the XJTU-SY bearing data, includes the following steps:

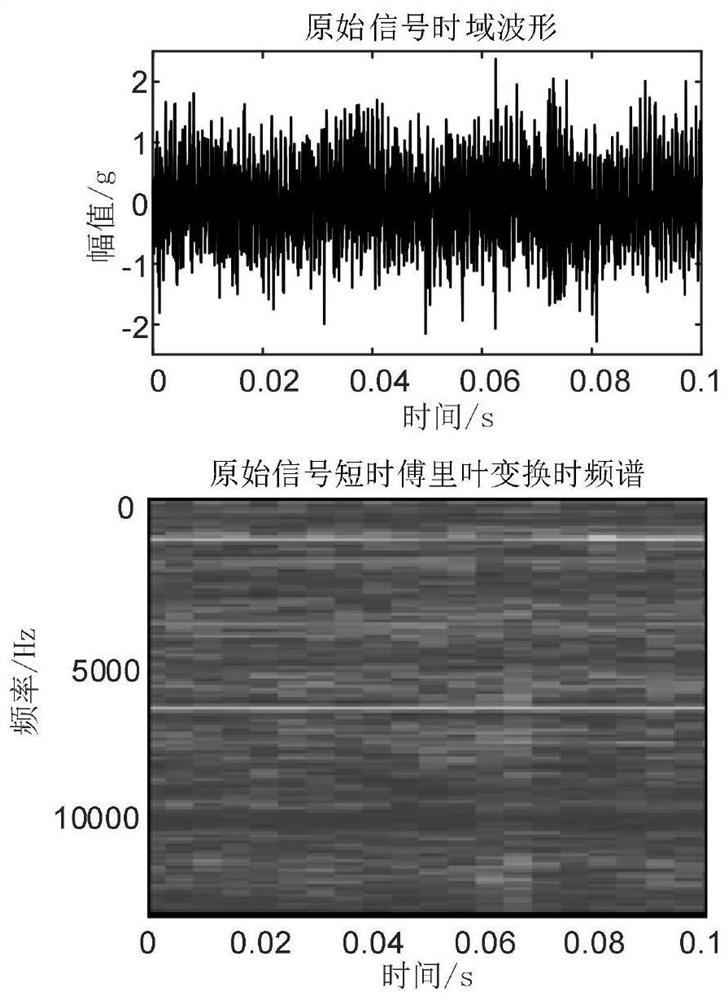

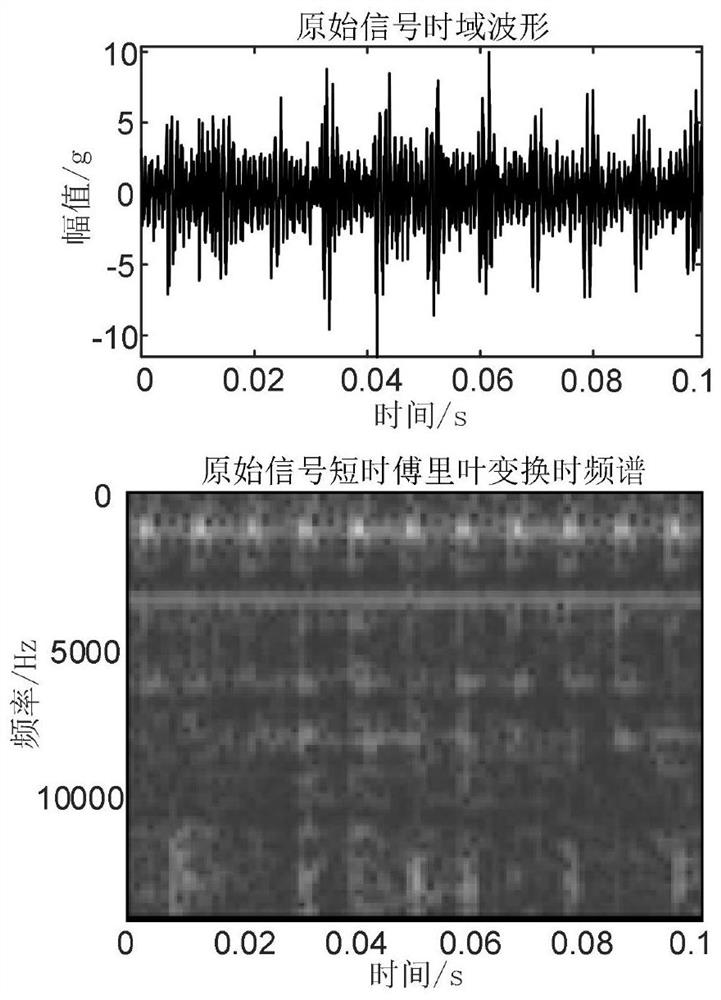

[0064] Step 1: Firstly, the original signal of the rolling bearing from normal to fault is collected at intervals through the vibration acceleration sensor, and the data is collected every one minute. The duration of each sampling is 1.28s, and the sampling frequency is 25.6KHz. A total of 123 groups are collected; The 0.1s time-domain waveforms of the 10 groups of original signals (before the failure) and the 80th group of original signals (after the failure) and the short-time Fourier transform spectrum are as follows: figure 2 , image 3 As shown, in the time spectrum, the harmonic com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com