Textile fabric cutting device with stretching and flattening mechanism

A technology for textile fabrics and cutting devices, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of unsmooth cutting, low efficiency, and wrinkled fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

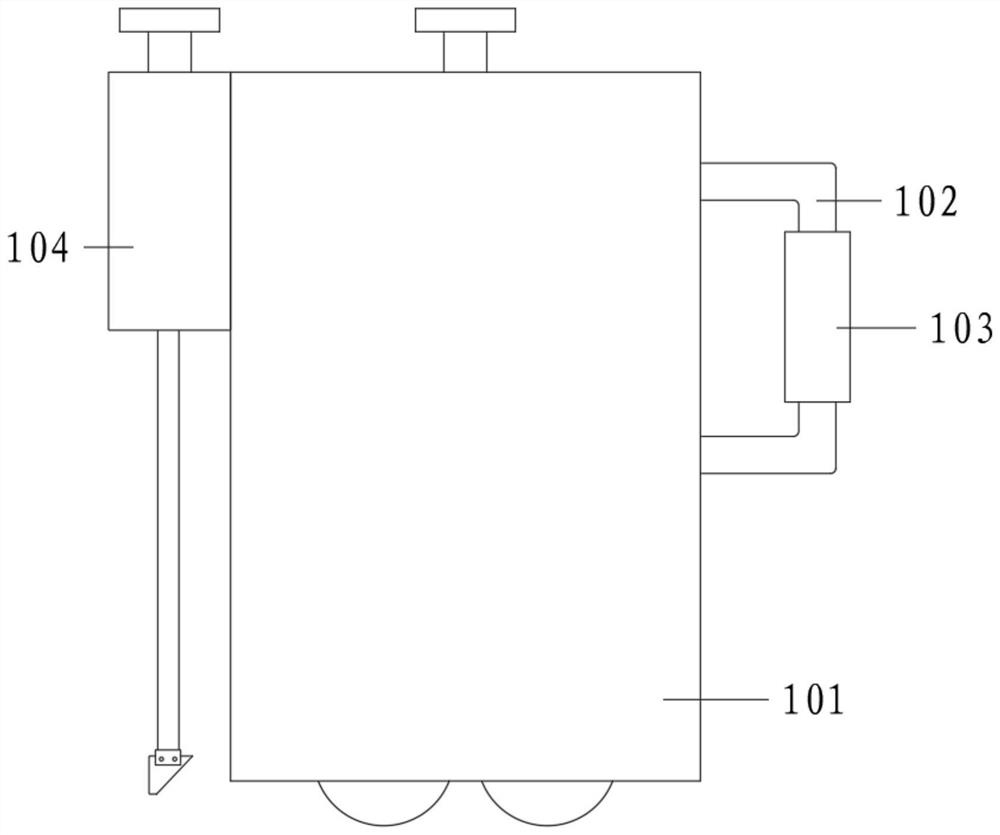

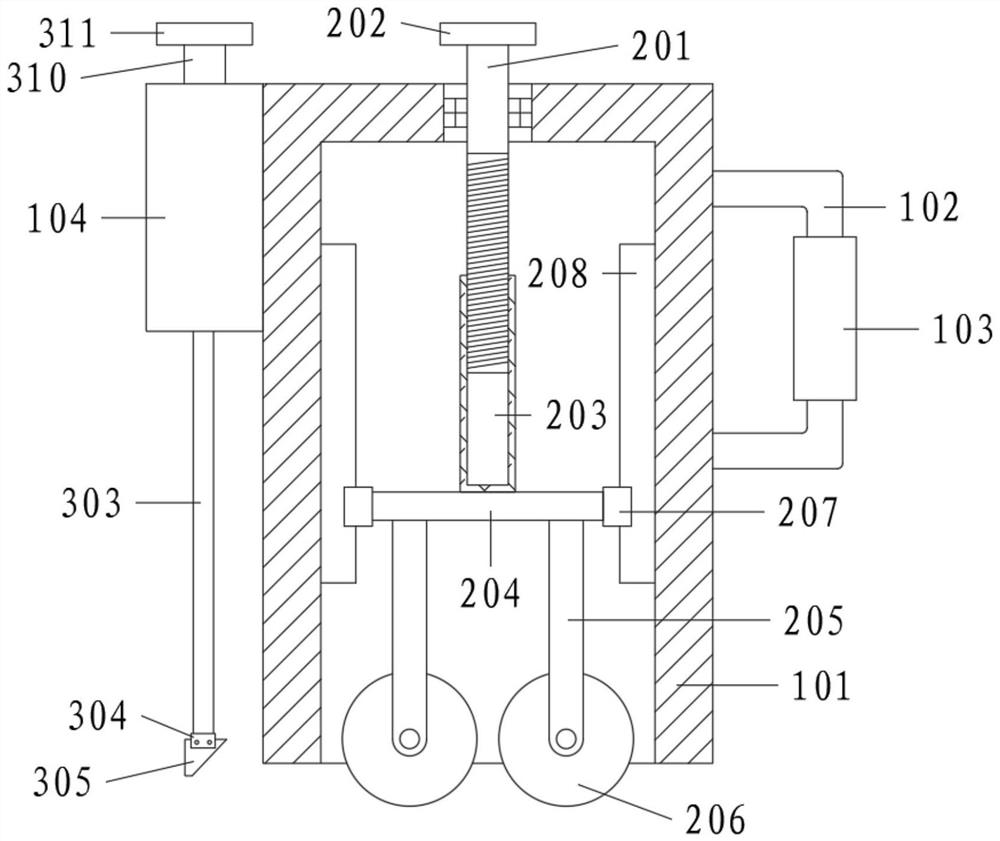

[0035] A textile fabric cutting device with a stretching mechanism, comprising a cover body 101, a handle 102 is connected to the right side of the cover body 101; Flat roller 206; the left side of the cover body 101 is provided with a cutting mechanism, the bottom end of the cutting mechanism is provided with a cutting blade 305, the cutting blades 305 are arranged at intervals along the front and rear direction, and the bottom end of the cutting blade 305 is lower than the bottom end of the cover body 101.

[0036] The stretching mechanism includes a No. 1 shaft 201, a No. 1 handwheel 202, an internal thread sleeve 203, a lifting plate 204, a roller bracket 205 and a stretching roller 206;

[0037] The No. 1 shaft 201 runs through and rotates to connect to the top of the cover body 101. The top end is connected with a No. 1 handwheel 202. The lower part is processed with threads and screwed into the inner thread sleeve 203; the inner thread sleeve 203 is connected to the lift...

Embodiment 2

[0046] In this embodiment, the distance between the two cutting blades 305 can be adjusted to meet different cutting needs.

[0047] On the basis of embodiment 1,

[0048] The cutting mechanism includes an adjustment shaft 301, a moving nut 302, a mounting rod 303, a blade holder 304 and a cutting blade 305;

[0049] The left side of the cover body 101 is connected with the installation cover 104, and the adjustment shaft 301 is installed in the installation cover 104 by rotating along the front and rear directions; the adjustment shaft 311 is symmetrically processed with two sections of threads with opposite directions, and is screwed with a moving nut 302; A blade frame 304 is connected to the bottom of the nut 302 through a mounting rod 303 , and a cutting blade 305 is mounted on the blade frame 304 .

[0050] The top of the second type slide block 306 is connected with the second type slide block 306, and the inner top of the installation cover 104 is fixed with a horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com