A kind of textile equipment based on environment-friendly cloth

A kind of textile equipment and environmental protection technology, applied in the field of textile equipment based on environmentally friendly fabrics, can solve problems such as adverse human health, reduced performance, no dust removal, etc., to improve work efficiency and performance, improve performance, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

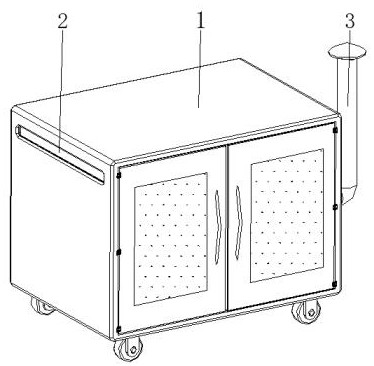

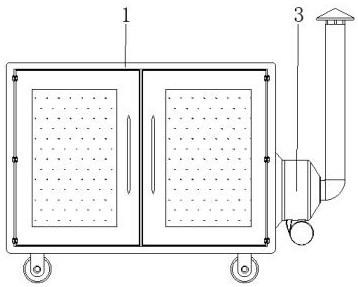

[0035] see Figure 1-9 , the present invention provides a technical solution: an environment-friendly cloth textile equipment, comprising a textile body 1, a blank inlet 2, and a cleaning device 3, the blank inlet 2 is arranged on the top side of the surface of the textile body 1, and the cleaning device 3 is arranged on the bottom side of the surface of the textile body 1;

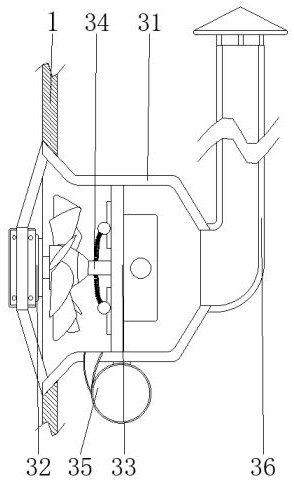

[0036] The cleaning device 3 is provided with a housing 31, a cooling device 32, an impurity removal device 33, a primary cleaning device 34, a dust suction mechanism 35, and an air duct 36. The housing 31 is fixed and connected to the bottom side of the surface of the textile body 1 to dissipate heat. Device 32 is arranged on the port of casing 31 and is positioned at the internal position of textile machine body 1, and impurity removal device 33 is arranged on the inside of casing 31 and the position near cooling device 32, and primary cleaning device 34 is arranged on the inside of casing 31 and Coope...

Embodiment example 2

[0038] The cooling device 32 is provided with a bracket 321, a drive motor 322, and an exhaust fan blade 323. The end of the bracket 321 is fixedly connected to the inner wall of the housing 31, and the surface of the drive motor 322 is fixedly connected to the bracket 321. The exhaust fan blade 323 is installed on the drive motor. The position of the output shaft of 322, the central position of the surface of the exhaust fan blade 323 and the side away from the drive motor 322 are connected with the primary cleaning device 34. When the drive motor 322 is turned on, the exhaust fan blade 323 will be driven, and then the negative pressure will The air, dust, fluff and other impurities in the textile machine body 1 are discharged into the housing 31, and the impurities are removed in time through the impurity removal device 33, so as to reduce the impact of impurities on the human body and the environment, and at the same time, the outside air enters the textile machine body 1, A...

Embodiment example 3

[0040] The impurity removal device 33 is provided with a frame 331, a filter screen 332, an arc bar 333, and a secondary cleaning device 334. The surface edge of the frame 331 is fixedly connected with the inner wall of the housing 31, and the central position of the frame 331 is connected to the primary cleaning device. The devices 34 are mated and connected, the filter screen 332 is arranged on the surface of the frame 331, the arc surface bar 333 is fixed on one side of the surface of the filter screen 332, and the secondary cleaning device 334 is arranged on the surface of the filter screen 332 and away from the arc surface bar One side of 333 is connected by rotation between the rotating rod 341 and the center of the filter screen 332. When the rotating rod 341 is driven by the exhaust fan blade 323 to rotate, the arc support spring 3441 and the knocking ball 3442 will rotate thereupon. Under the action of the elastic support of the arc-shaped support spring 3441, the knoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com