Blow-drying and setting equipment for clothing processing and use method thereof

A technology of clothing and equipment, which is applied in the field of drying and shaping equipment for clothing processing, can solve the problems of wasting intermediate transfer time, low ironing efficiency, and slow drying process, and achieve the goal of improving efficiency, improving transfer efficiency, and improving pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

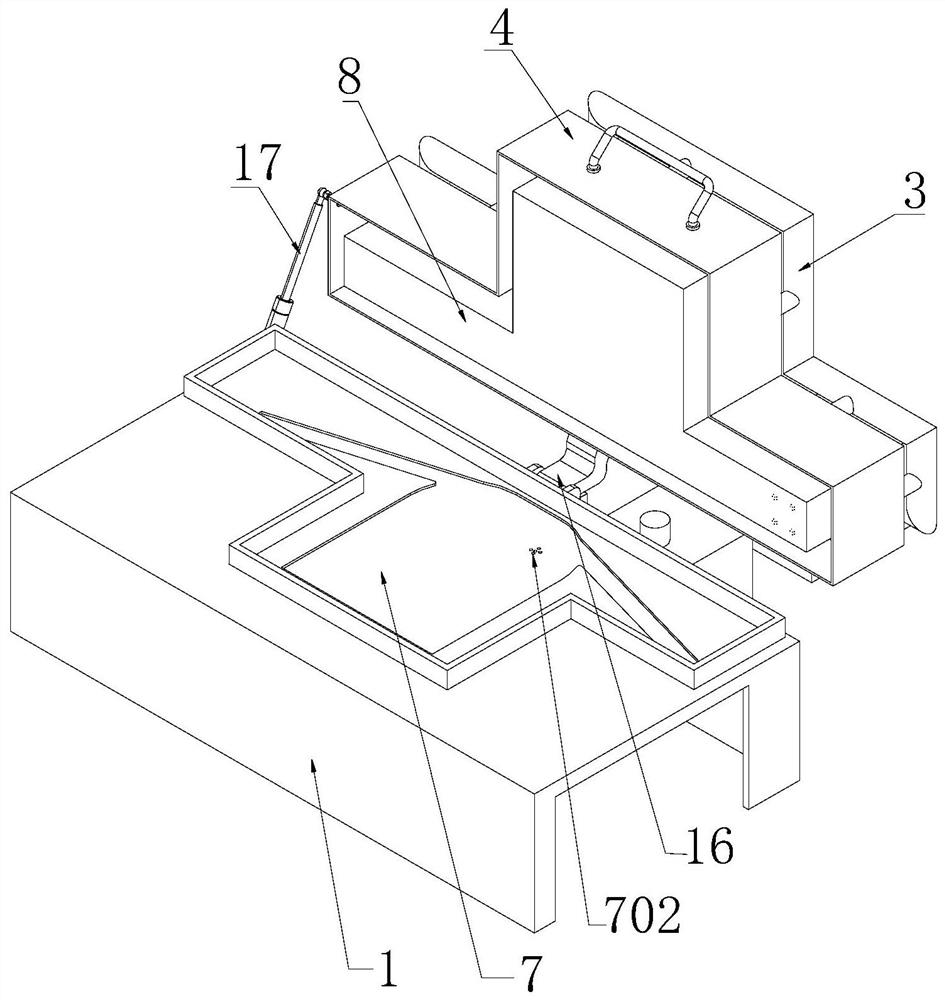

[0034] Embodiment one, refer to figure 1 and figure 2 , also includes a rotary hinge 16 and a second telescopic cylinder 17, the rotary hinge 16 is installed between the back of the hot air cover 4 and the back of the operating table 1, and the two ends of the second telescopic cylinder 17 are hinged on the side of the hot air cover 4 and the operating table 1, the rotating hinge 16 is used to rotate and open the hot air cover 4, the lifting end of the second telescopic cylinder 17 can drive the hot air cover 4 away from or close to the clothing ironing table 7, and the bottom of the air collection cavity 701 is connected with a negative pressure tube 9.

[0035]Embodiment 1 The specific operation method is that after the operator puts the clothing on the clothing ironing table 7 each time, the lifting end of the second telescopic cylinder 17 drives the hot air cover 4 to make the steam nozzle 8 close to the clothing ironing table 7 When the ironing distance of the clothing...

Embodiment 2

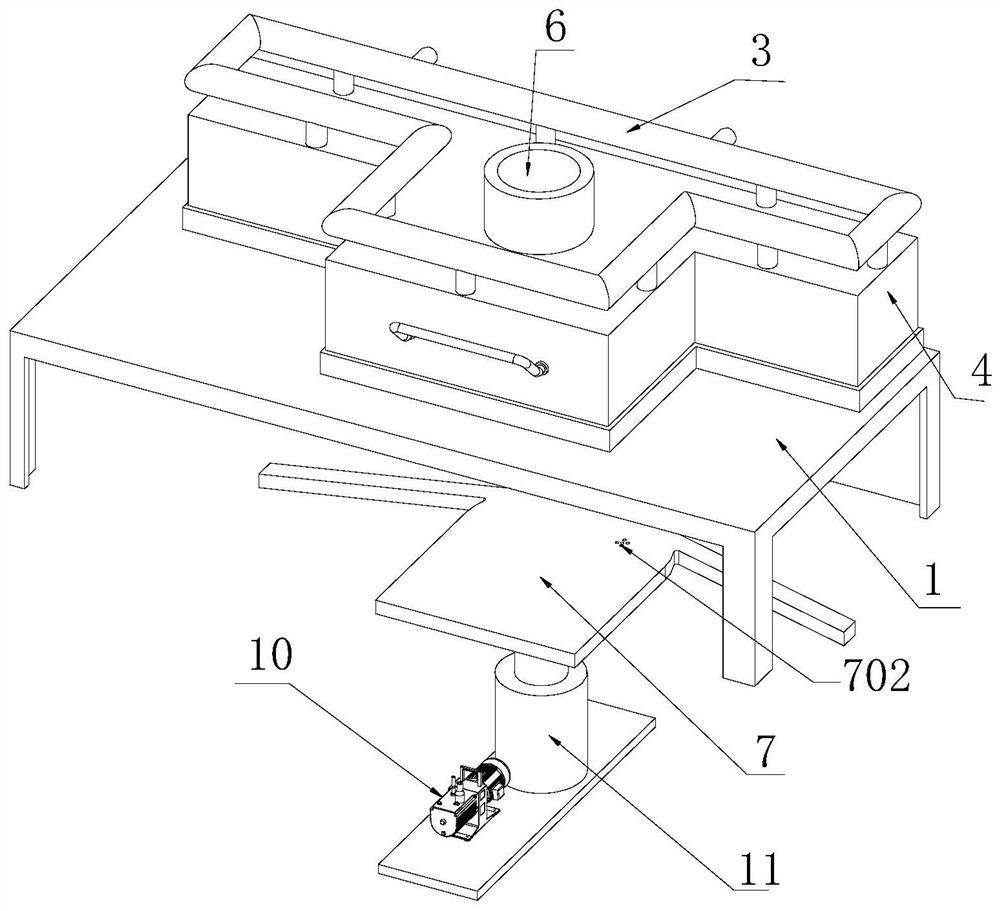

[0036] Example 2, please refer to image 3 , Figure 4 , Figure 7 As shown, it also includes a negative pressure pipe 9 and a vacuum pump 10. An air collection cavity 701 is provided inside the clothing ironing table 7, and several air holes 702 communicating with the air collection cavity 701 are provided on the upper surface of the clothing ironing table 7. , when ironing, the air collection cavity 701 communicates with the vacuum pump 10 through the negative pressure tube 9 .

[0037] It also includes a first telescopic cylinder 11, the lifting end of the first telescopic cylinder 11 can drive the clothing ironing table 7 away from or close to the steam nozzle 8, the table top of the operating table 1 is provided with a through groove 101, and the clothing ironing table 7 is arranged in the through channel. Below the groove 101, a sealing gasket 12 is arranged between the outer edge of the upper surface of the clothing ironing table 7 and the bottom surface of the operat...

Embodiment 3

[0040] Embodiment three, please refer to Figure 5 , Figure 6 , Figure 7 It is shown on the basis of the second embodiment, in order to facilitate the disassembly and replacement of the clothing ironing table 7, and to further improve the safety and the efficiency of styling.

[0041] In this embodiment, a limit plate 13 is also included, and the limit plate 13 is fixedly connected to the lifting end of the first telescopic cylinder 11, and the clothing ironing table 7 is limitedly arranged on the limit plate 13, and the lifting of the first telescopic cylinder 11 The end can drive the clothing ironing table 7 away from or close to the steam nozzle 8 through the limiting plate 13 .

[0042] It also includes an endless conveyor belt 14, the endless conveyor belt 14 is arranged above the limiting plate 13, and a through hole 1401 is provided on the endless conveyor belt 14 corresponding to the position of the limiting plate 13, and the through hole 1401 is used to pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com