Loudspeaker voice coil shaping tooling and shaping process

A loudspeaker and voice coil technology, which is applied in the field of loudspeakers, can solve the problems that the outer diameter of the voice coil cannot ensure the uniformity of the size, the size of the voice coil cannot be guaranteed, and the sound quality of the loudspeaker is large, so as to meet the requirements of mass production, prevent deformation, and ensure quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

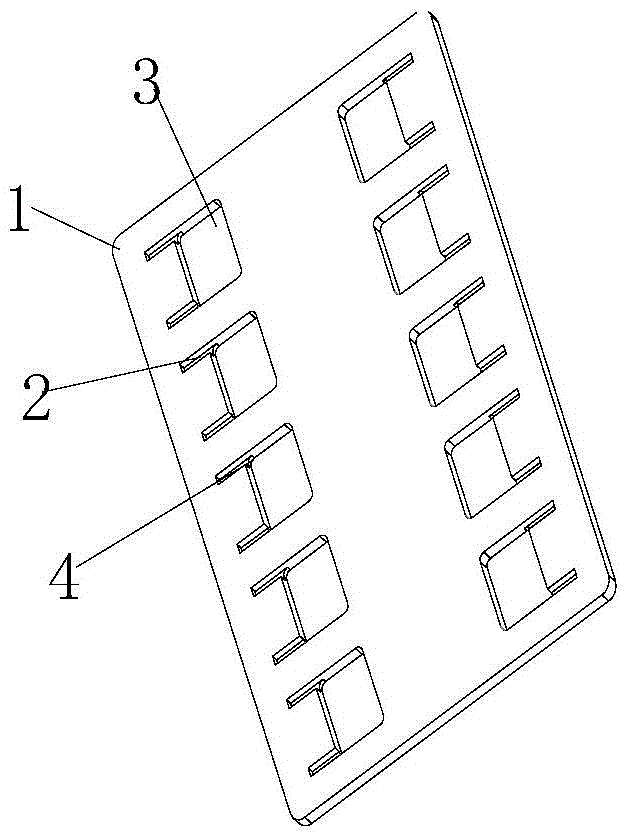

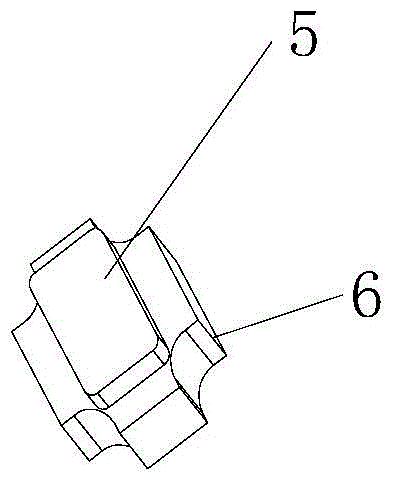

[0020] Such as figure 1 with figure 2 The loudspeaker voice coil shaping tool shown includes a tooling substrate 1, which is characterized in that: the tooling substrate 1 is uniformly provided with accommodating holes 3 for placing the speaker voice coil. In this embodiment, the tooling is basically symmetrically arranged with two A row of accommodation holes, the tooling substrate 1 on one side of the accommodation hole 3 is provided with a lead groove 2 for accommodating the lead wire of the voice coil, and also includes an ejector block that cooperates with the accommodation hole 3, and the ejector block includes an ejector body 5 and a The holding part 6, the ejector body 5 and the holding part 6 are integrally arranged, and the outer diameter of the ejector body 5 is larger than the outer diameter of the voice coil and smaller than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com