Method for preparing H13 steel through electroslag remelting

An electroslag remelting and remelting technology, which is applied in the metallurgical field, can solve the problems of difficulty in meeting the requirements of high-quality die steel, secondary oxidation of molten steel, and reducing the yield of rare earths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

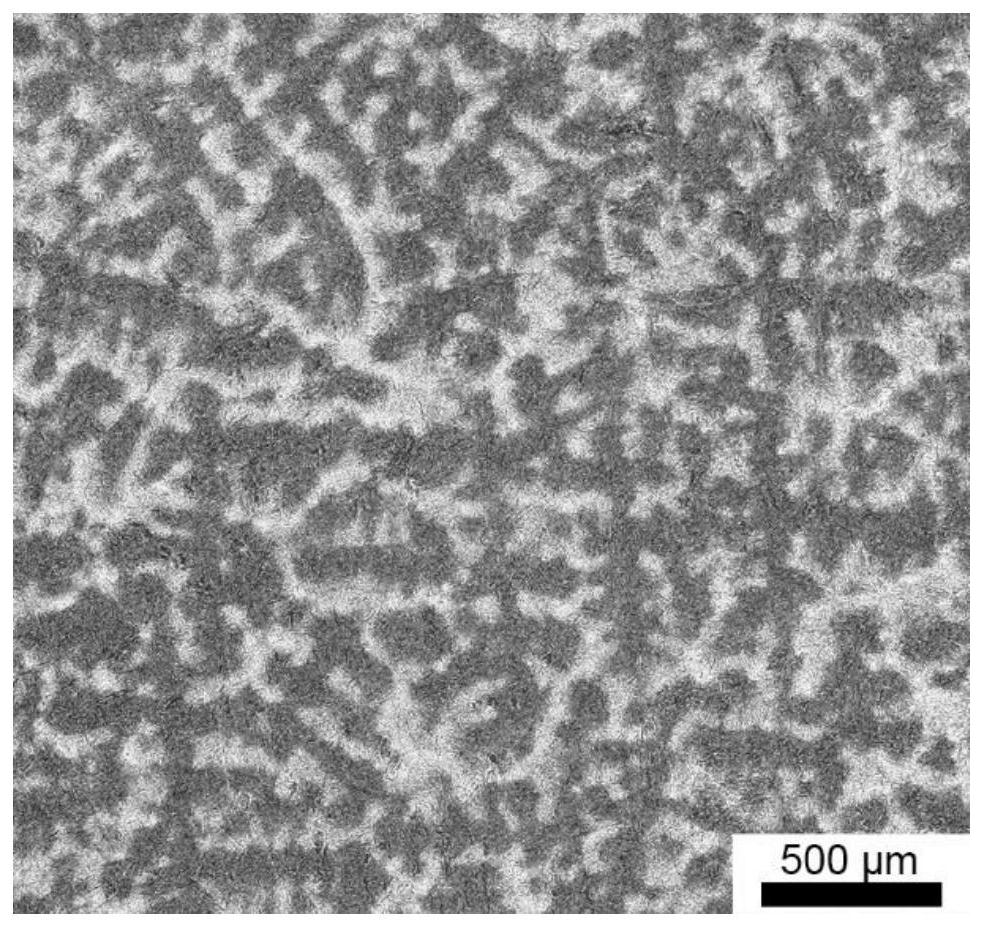

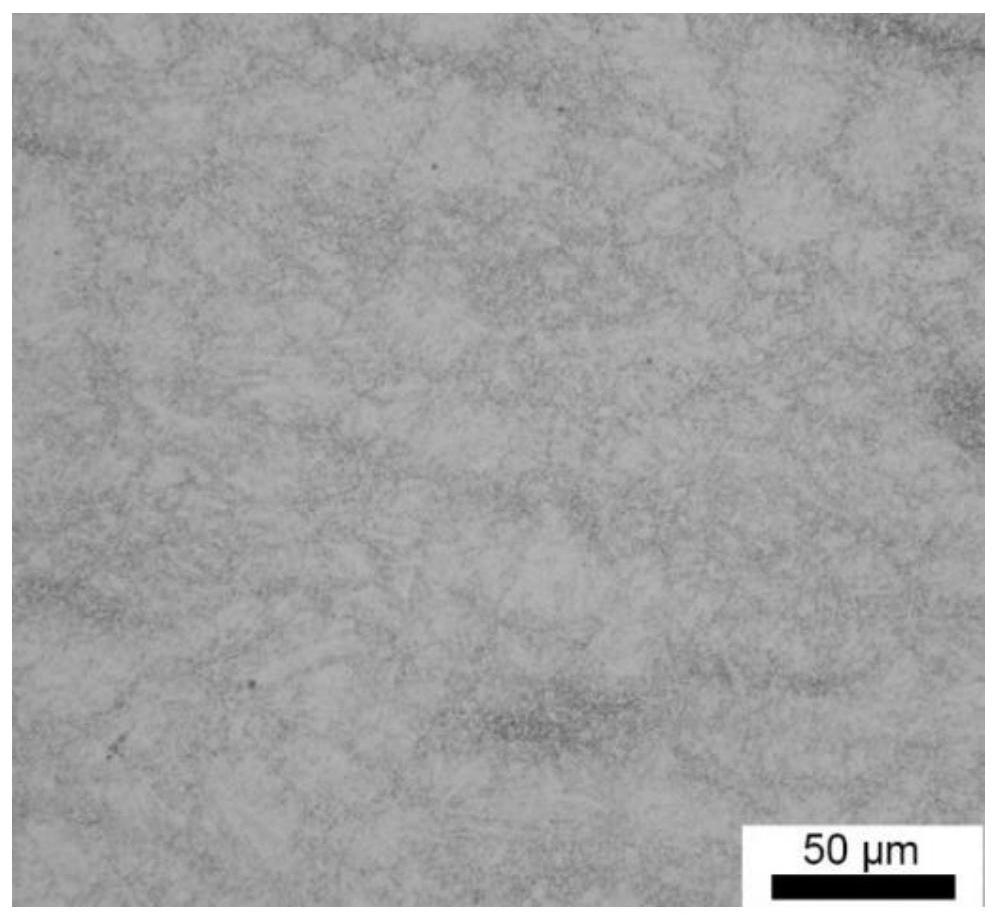

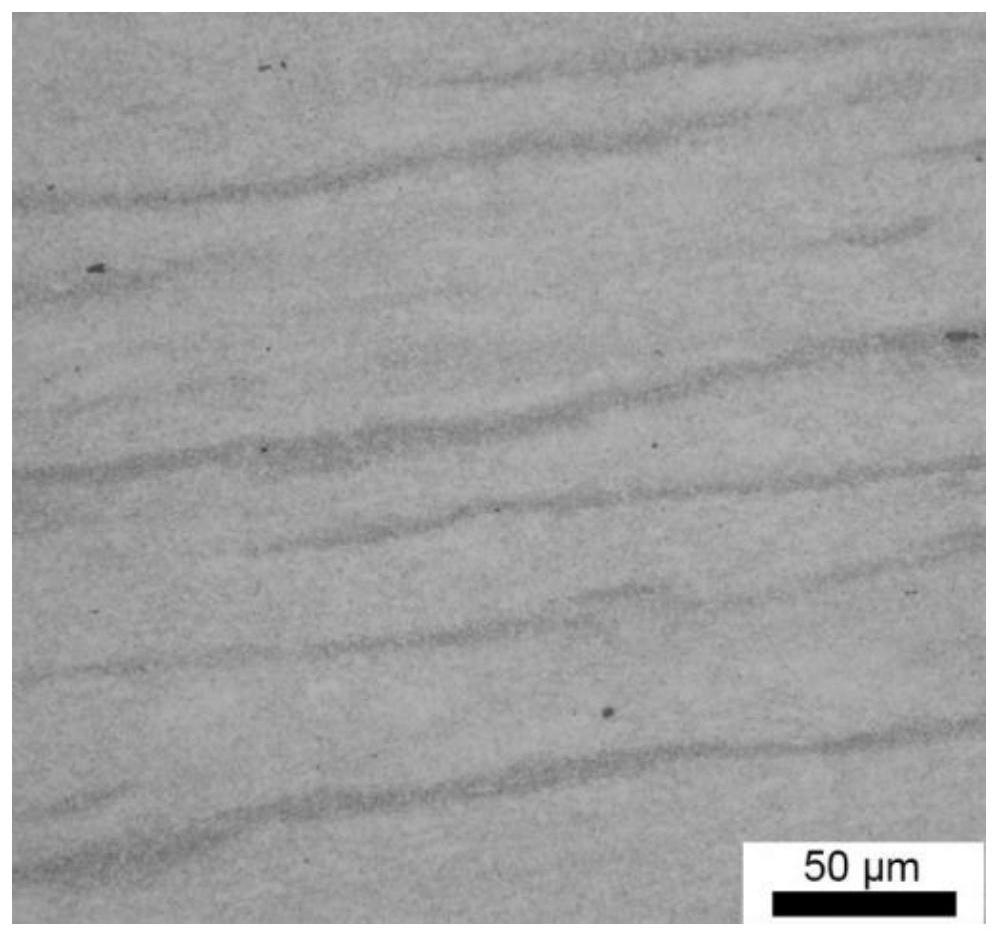

Image

Examples

preparation example Construction

[0039] The method for preparing the consumable electrode is not particularly limited in the present invention, and the method for preparing the consumable electrode of H13 steel well known in the art can be adopted.

[0040] In the present invention, the pre-melted slag includes the following components in mass percentage: CaF 2 40-50 parts, CaO 15-30 parts, rare earth oxide 20-30 parts, Al 2 o 3 5-15 parts, 1-3 parts of MgO and 3-5 parts of NaF, preferably CaF 243-48 parts, CaO 18-25 parts, rare earth oxide 23-28 parts, Al 2 o 3 8 to 12 parts, 1.5 to 2.5 parts of MgO and 3.5 to 4.5 parts of NaF. In the present invention, by adjusting the composition of the pre-melting slag, that is, calcium-aluminum compound as the main body, adding rare earth oxides and controlling its content within the above range, the steel slag interaction and reducing agent addition at high temperature of electroslag remelting The reduction of rare earth oxides finally makes the rare earth elements...

Embodiment 1

[0072] Using H13 steel to be treated as a consumable electrode, using pre-melted slag and a reducing agent to perform electroslag remelting on the consumable electrode to obtain H13 steel;

[0073] Among them, the consumable electrode is composed of the following components in mass percentage: C 0.40%, Si 1.10%, Mn 0.40%, Cr 5.25%, Mo 1.35%, V 0.9%, O 0.002%, S 0.0019%, P 0.02% and the balance Fe; the target rare earth content of H13 steel is 0.022%;

[0074] The pre-slag is composed of the following components in mass percentage: CaF 2 40%, rare earth oxide 25% (rare earth oxide is made of 20% CeO by mass percentage 2and 80% La 2 o 3 Composition), CaO 19%, Al 2 o 3 10%, MgO 3% and NaF 3%;

[0075] The reducing agent is composed of the following components in mass percentage: Si 62.0%, Ca 27.2% and the balance Fe.

[0076] The amount of reducing agent and pre-slag has a relationship as shown in formula I; the amount of pre-slag used is calculated according to formula II...

Embodiment 2

[0083] This embodiment requires that the target rare earth La content of H13 steel is 0.018%; the pre-slag component in Example 1 is replaced by the following mass percentage components: CaF 2 40%, La 2 o 3 20%, CaO 20%, Al 2 o 3 15%, MgO 1% and NaF4%; other technical features are the same as in Example 1 to obtain the H13 steel S2 sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com