Flaky nano ZIF-8 material, and synthesis method and application thereof

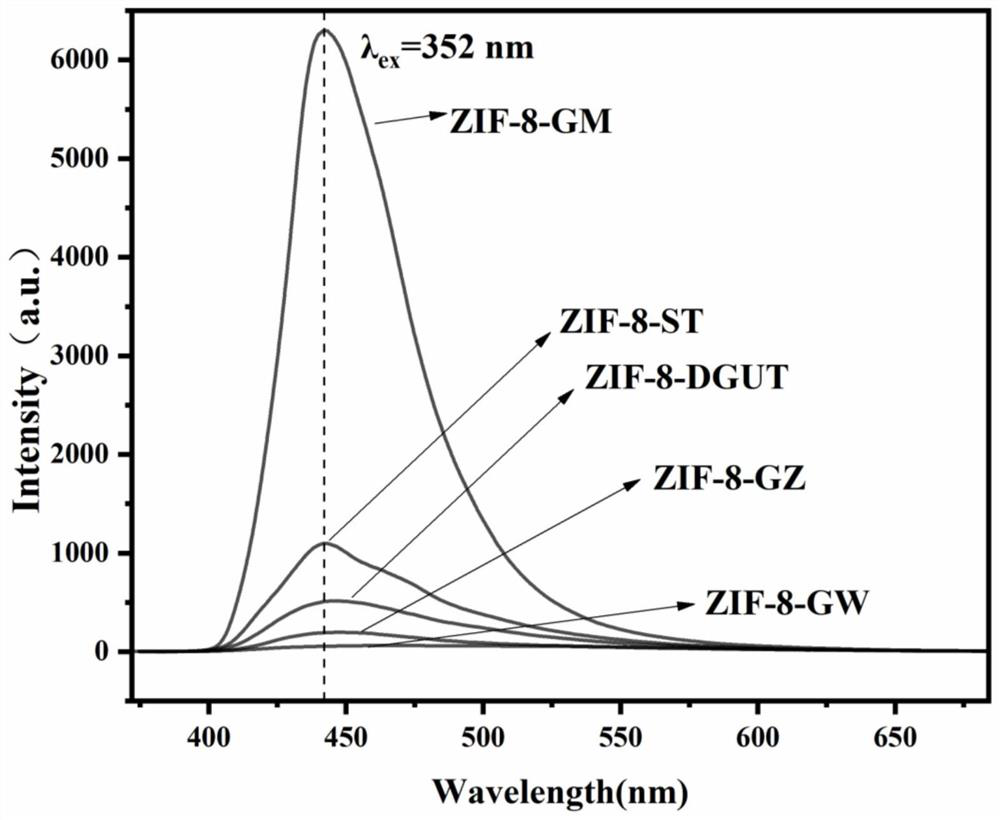

A kind of ZIF-8, nanotechnology, applied in the field of synthesis of flake nano ZIF-8 materials, can solve the problems of poor fluorescence performance of ZIF-8 and unfavorable sensing applications, etc., and achieve friendly synthesis conditions, obvious effects, and high-sensitivity detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

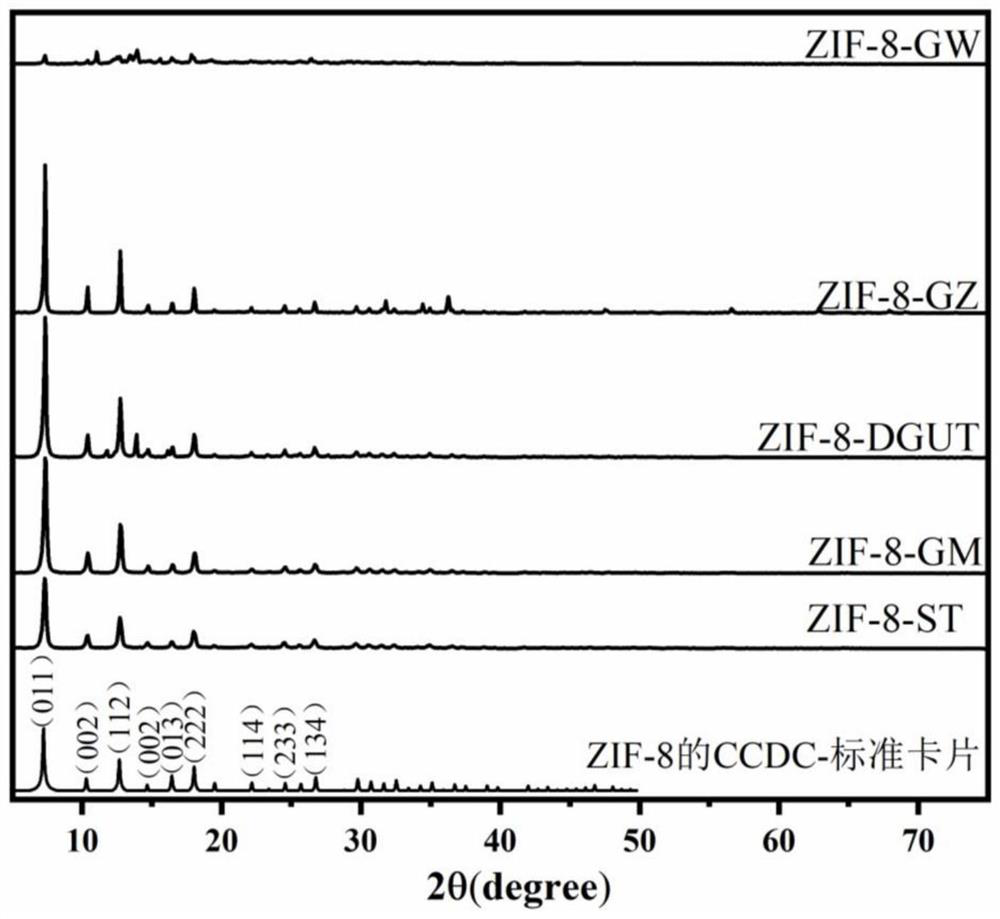

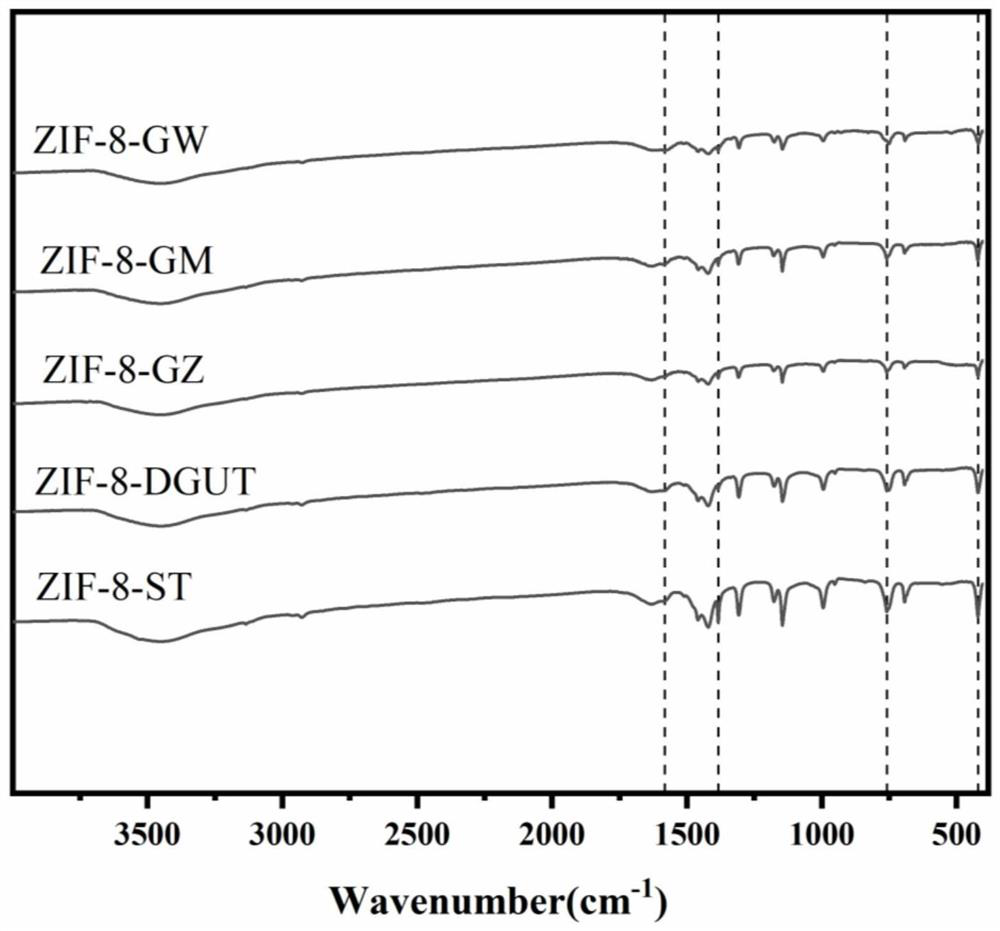

[0032] Specific implementation mode 1: This implementation mode is a kind of flake nano ZIF-8 material which is ground into a transparent colloid by 2-methylimidazole and zinc acetate dihydrate, then adding 2-methylimidazole and alkali with a molar ratio of 1:1.5 The alkali of ~2.5 is ground again, and the material obtained by methanol centrifugation is used for post-processing, in which 2-methylimidazole is the organic ligand, zinc acetate dihydrate is the metal node, alkali is the auxiliary agent, and 10-15mL methanol is the solvent during centrifugation.

specific Embodiment approach 2

[0033] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: a kind of flaky nano ZIF-8 material is ground into a transparent colloid by 2-methylimidazole and zinc acetate dihydrate, and then added 2-methylimidazole The alkali with a molar ratio of 1:1.5 to 2.0 is ground again, and the material obtained by methanol centrifugation is used for post-processing, in which 2-methylimidazole is the organic ligand, zinc acetate dihydrate is the metal node, and the alkali is the auxiliary agent. 15mL of methanol was used as the solvent for centrifugation. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: a kind of flake nano ZIF-8 material is ground to transparent colloid by 2-methylimidazole and zinc acetate dihydrate, then add 2 -Methylimidazole and alkali with a molar ratio of 1:2.0 to 2.5 are ground again, and the post-treatment uses the material obtained by methanol centrifugation, in which 2-methylimidazole is the organic ligand, zinc acetate dihydrate is the metal node, and the alkali is the auxiliary 10-15mL methanol is used as the solvent for centrifugation. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com