Plug-in plastic repair welding gun

A plug-in, welding gun technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problems of uneven weld seam, low work efficiency, prolong operation time, etc., achieve smooth weld seam, prolong service life, and safety high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

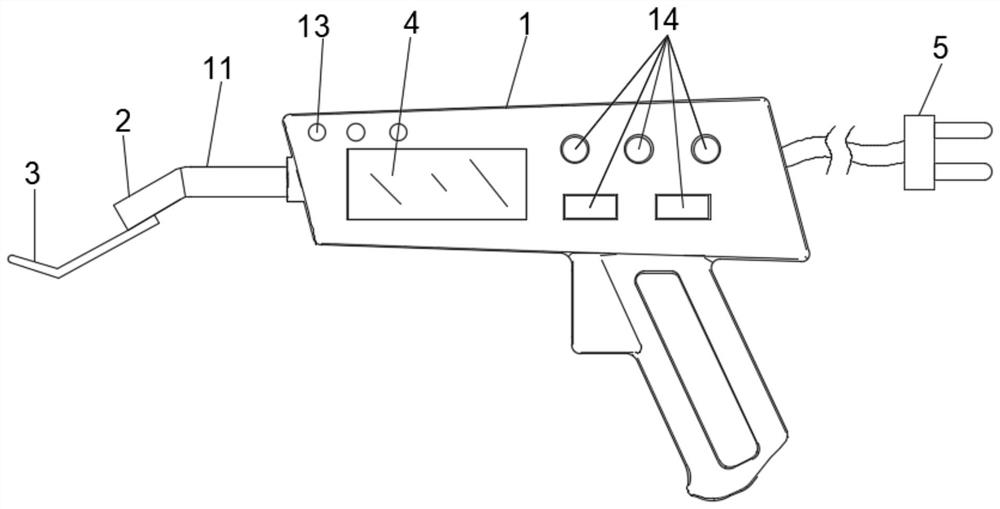

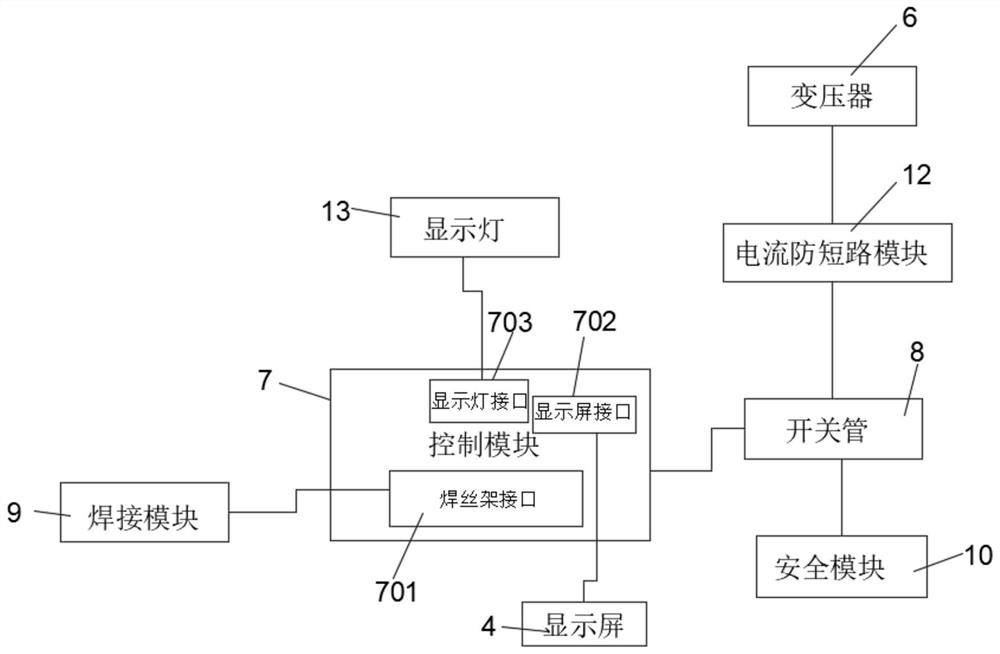

[0024] see Figure 1-4 As shown, the present invention provides a technical solution of a plug-in plastic repair welding torch: a plug-in plastic repair welding torch, including a welding torch body 1 and a nozzle 11 matched with the welding torch body 1, and a rotating shaft is installed on the nozzle 11. Joint 2, a repair head 3 is installed on one side of the adapter 2, specifically, the nozzle 11 and the adapter 2, the adapter 2 and the repair head 3 are fixedly connected by screws, as Figure 4-7 As shown, the repair head 3 is provided with four shapes, and different repair heads 3 are suitable for welding different plastics, which is beneficial for people to use. The front of the welding torch body 1 is fixedly equipped with a display screen 4 and several control buttons 14. Specifically, The display screen 4 adopts an LED liquid crystal display screen, and the control buttons 14 are set according to requirements. The inside of the welding torch body 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com