Process for preparing powder metallurgy material

A powder metallurgy and process technology, which is applied in the field of powder metallurgy material preparation, can solve the problems of poor quality of powder metallurgy materials and long preparation time, and achieve the effects of improving performance, small size and improving rolling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

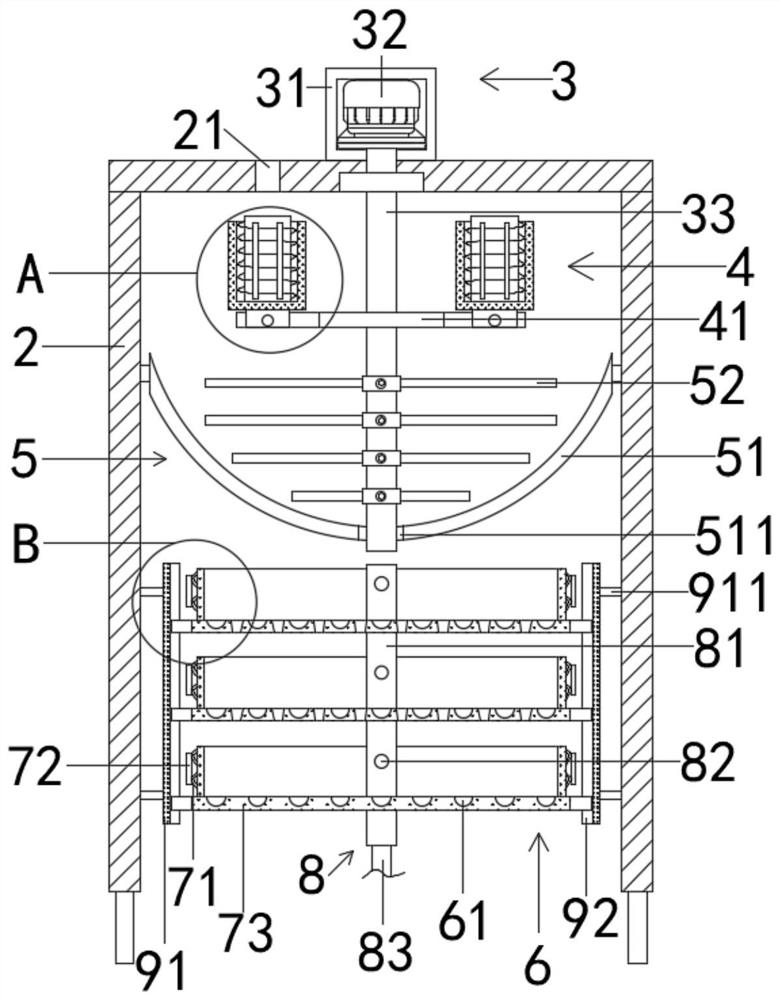

[0050] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0051] The present invention provides a process for preparing powder metallurgy materials, which has the advantages of improving quality and shortening preparation time. Please refer to Figure 1-Figure 8 , including the following specific steps:

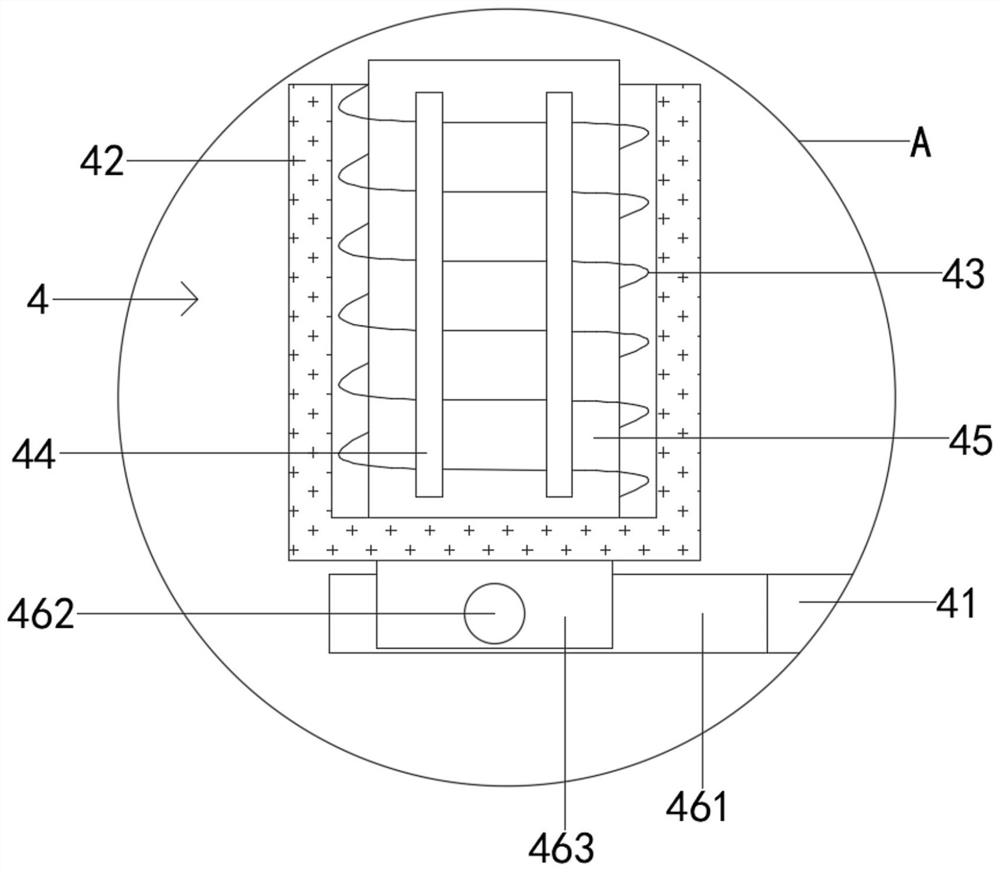

[0052] S1, the rotating shaft 33 is rotated by the large servo motor 32. When the rotating shaft 33 rotates, the circular plate 41 and the agitator 52 will be driven to rotate, so that the rotating circular plate 41 will move the smelting box 42 to the feeding hole 21. Below, so as to achieve the corresponding placing of multiple groups of materials into the crucible 45;

[0053] S2, when the material is put into the smelting box 42, the material in the crucible 45 is melted through the induction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com