Preparation method of flexible gas sensor for fabric

A gas sensor and sensor technology, used in instruments, scientific instruments, textiles and papermaking, etc., can solve the problems of inconvenient wearing, affecting the breathability and comfort of protective clothing, and achieve regular pore arrangement, easy regulation and detection. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The method for preparing a flexible gas sensor for fabrics in this embodiment includes the following steps:

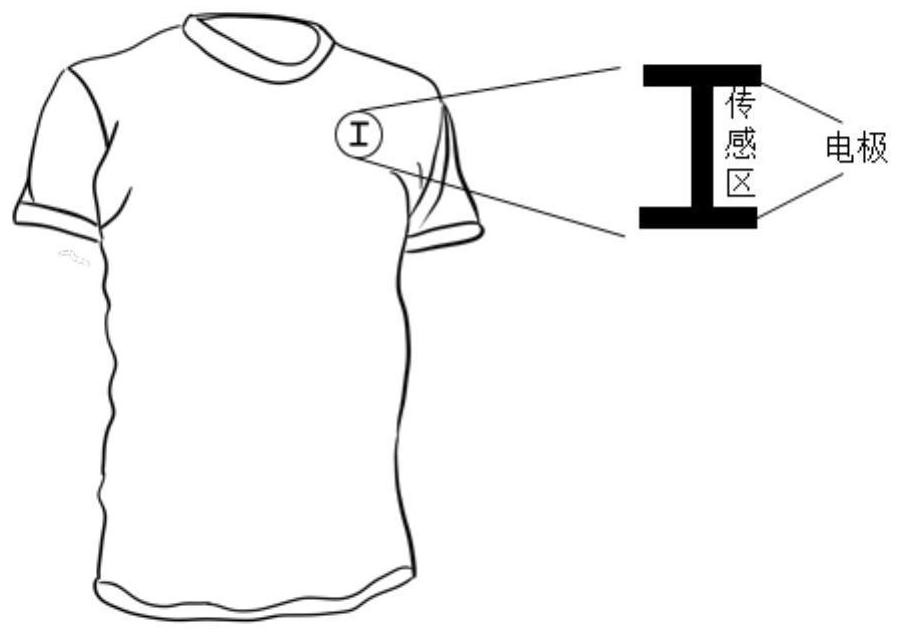

[0039] Step 1. Select an area on the fabric as the sensor processing area, and the fabric as the flexible substrate of the sensor;

[0040] Step 2. Weigh the alcohol-soluble phenolic resin and the block copolymer F127 according to the mass ratio of 2:1, and the alcohol-soluble phenolic resin and the block copolymer F127 as the solute. Proportionally weigh absolute ethanol, using absolute ethanol as a solvent; pour the weighed alcohol-soluble phenolic resin and block copolymer F127 into absolute ethanol for stirring, the stirring temperature is 40°C, and the stirring rate is 800 rpm, The stirring time is 4 hours, until the alcohol-soluble phenolic resin and the block copolymer F127 are completely fused, and the coating solution is prepared;

[0041] Step 3. Put the coating solution in a vacuum box for degassing treatment for 0.5h to remove the air bubbles in the...

Embodiment 2

[0045] In this embodiment, the ratio of raw materials for preparing the coating solution in step 2 is different from that in Example 1, and all the other steps are the same as in Example 1, specifically:

[0046] Weigh the alcohol-soluble phenolic resin and the block copolymer F127 according to the mass ratio of 1:1, and then weigh the absolute ethanol according to the mass ratio of the solute to the solvent of 1:4 to prepare the coating solution.

[0047] image 3 For the electron microscope picture of the porous carbon obtained in this example, the carbon dioxide laser ablated the coated area of the fabric to form a regular porous structure with a pore size of 100-200 nm.

[0048] Figure 5 The sensor that obtains for this embodiment measures the continuous response graph of NO gas, wherein, R represents the resistance of sensor after changing in gas, R 0 Indicates the initial resistance; It can be seen from the figure that as the gas concentration increases, the respons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com