Construction method of large-diameter cast-in-place pile in complex strata

A technology for complex strata and cast-in-place piles, applied in sheet pile walls, infrastructure engineering, construction, etc., to solve problems such as large area of cracks connected to pile holes, large hole wall area of large-diameter pile holes, and untimely mud replenishment. , to increase the connection stability, good construction effect, and increase the effect of crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

[0049] A concrete mixture for retaining piles, comprising the following components:

[0050] Water, cement, fly ash, sand, stone, water reducing agent, early strength agent, anti-cracking agent.

[0051] Among them, the anti-cracking agent is composed of magnesium chloride, magnesium sulfate, and magnesium nitrate in a mass ratio of 1:0.3:0.5.

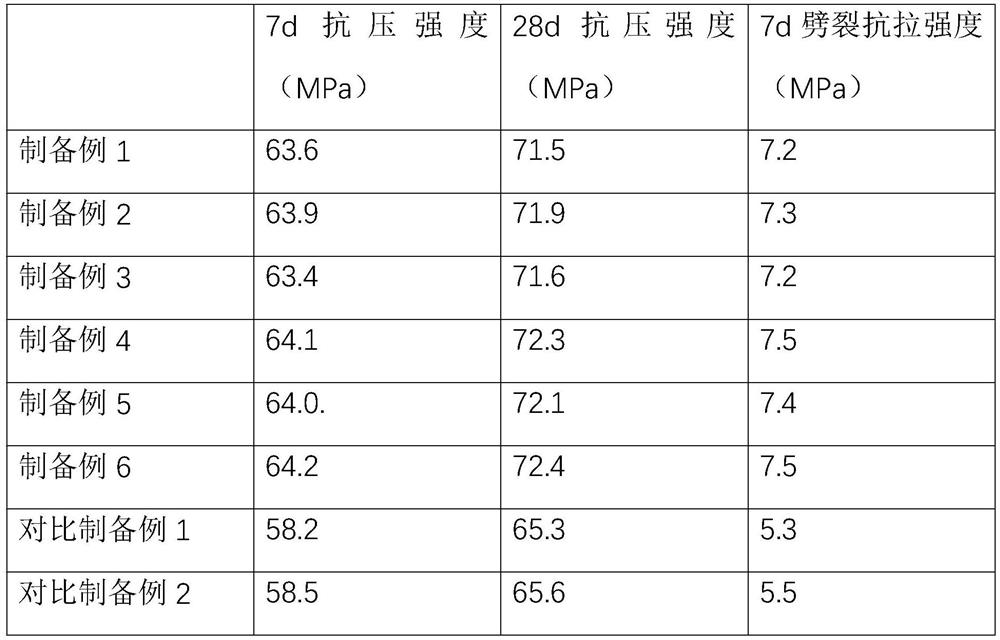

[0052] See Table 2 for details of the input amounts (in Kg) of each raw material in Preparation Examples 1-3.

[0053] Table 2

[0054] Unit(Kg) Preparation Example 1 Preparation example 2 Preparation example 3 water 150 152 151 cement 510 510 511 fly ash 38 40 39 sand 680 690 688 stone 990 1000 991 Superplasticizer 2.4 2.6 2.5 early strength agent 19 21 20 Anti-crack agent 9 11 10

[0055] The preparation method of pile protection concrete mixture in preparation example 1-3 is as follows:

[0056] Put water, cement, fly ash, sand and stone into the ...

preparation example 4-6

[0058] A kind of concrete mixture for protecting piles, compared with embodiment 3, the only difference is that it also includes the following components:

[0059] steel fiber.

[0060] In Preparation Examples 4-6, see Table 3 for the specific input amount (unit: Kg) of steel fibers.

[0061] table 3

[0062] Unit(Kg) Preparation Example 4 Preparation Example 5 Preparation example 6 steel fiber 3.8 4.2 4

[0063] In the preparation method of the pile protection concrete mixture of the preparation examples 4-6, the steel fiber is put into the stirring tank together with water, cement, fly ash, sand and stone for stirring.

preparation example 7

[0065] A kind of cast-in-situ pile concrete mixture, the preparation method is as follows:

[0066] Put 100Kg of water, 250Kg of cement, 34.2Kg of fly ash, 421.3Kg of sand, and 717.4Kg of stone into the stirring tank at a speed of 60r / min and stir for 15min, then put in 1.23kg of water reducing agent at a speed of 60r / min and stir for 20min. Obtain concrete mix for cast-in-situ piles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com