Device and method for pulling out pre-buried steel pipe in post-tensioning prestressed concrete construction

A concrete and prestressed technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of easy hole collapse and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

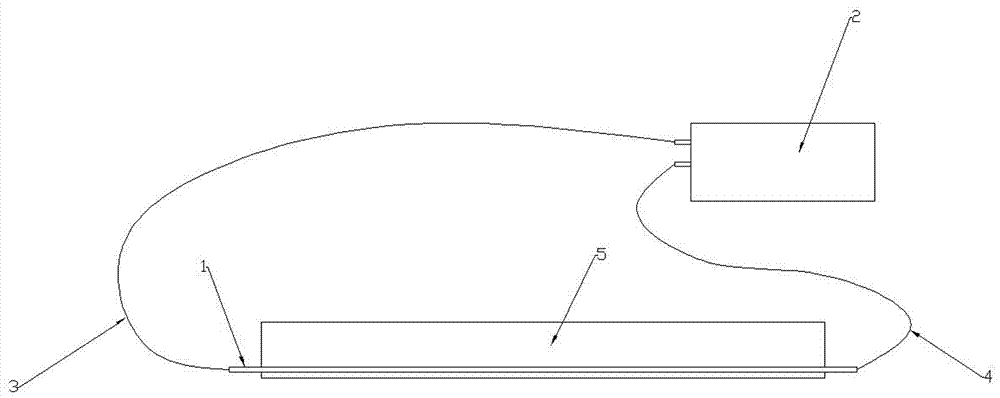

[0006] The specific embodiment of the present invention is described below in conjunction with accompanying drawing

[0007] see figure 1 Firstly, according to the conventional method of post-tensioning prestressed concrete construction, prestressed core-pulling steel pipes are buried in the formwork, and the concrete is poured. Connect the two ends of the steel pipe 1, then turn on the power supply of the electric heating device 2, quickly heat the steel pipe 1 with low voltage and high current, cut off the power supply after the steel pipe 1 is heated to a certain degree, remove the positive and negative wires, and quickly pass the steel pipe 1 through Cool the steel pipe 1 with cold water, the cooled steel pipe 1 will be disengaged from the concrete hole, and the steel pipe can be pulled out.

[0008] Note: Before the steel pipe 1 is pre-embedded in the formwork, it is still necessary to apply a release agent according to the conventional method to prevent the steel pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com