Preparation method of electronic-grade choline hydroxide solution

An electronic-grade choline hydroxide technology, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of aminohydroxyl compounds, can solve the problems of low toxicity and side effects, and achieve clean production processes, safe production processes, and metal ion production. The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

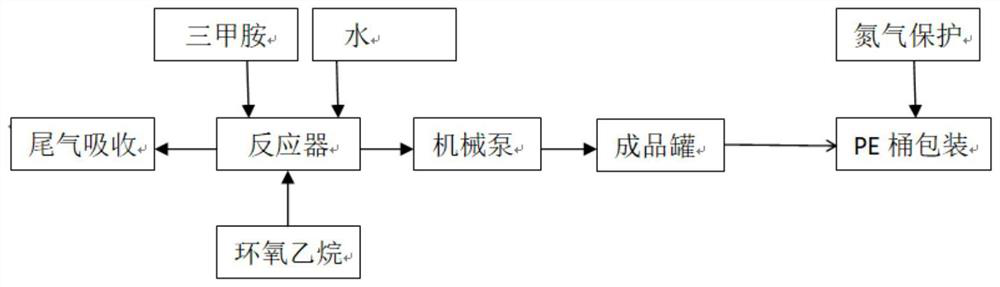

[0022] Such as figure 1 Shown, the preparation method of a kind of electronic grade choline hydroxide of the present application comprises the steps:

[0023] Mix trimethylamine and water in the reactor according to the molar ratio of 1:10, when the trimethylamine is completely dissolved, slowly feed ethylene oxide into the reactor. The molar ratio of trimethylamine and ethylene oxide is 1:1.05 for feeding. Strictly control the reaction temperature at 40-45°C, and the reaction pressure at 0.20Mpa. After the feeding of ethylene oxide is completed, the solvent reaction is completed after stirring for another 60 minutes.

[0024] After the reaction is completed, the residual trimethylamine in the choline hydroxide solution is distilled out by utilizing the waste heat in the reaction process under reduced pressure, and the control index is till the trimethylamine≤400ppm. When the sampling is qualified, the choline hydroxide solution is prepared, and the content is controlled to ...

Embodiment 1

[0052] Take trimethylamine with a content of 99% and high-purity water and send them into the reactor according to the molar ratio of 1:10. After the trimethylamine is completely dissolved, slowly add ethylene oxide into the reactor. The ratio is trimethylamine and The molar ratio of ethylene oxide is 1:1.05, the temperature is controlled at 40-45°C, the pressure is controlled at 0.20Mpa, and the excess heat is removed through the heat transfer medium.

[0053] After feeding, stir for 60 minutes, and remove residual trimethylamine under reduced pressure.

[0054] After removing excess trimethylamine, add a total amount of 2‰ stabilizer to the reactor and stir for 30 minutes to obtain 40-45% choline hydroxide solution, which is sent into a storage tank by mechanical pump for standby.

[0055] This experiment chooses this experiment to use the mechanical pump to send the choline hydroxide solution into the nitrogen-sealed finished product tank through micro-membrane filtration. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com