Synthesis method and device of methane chloride

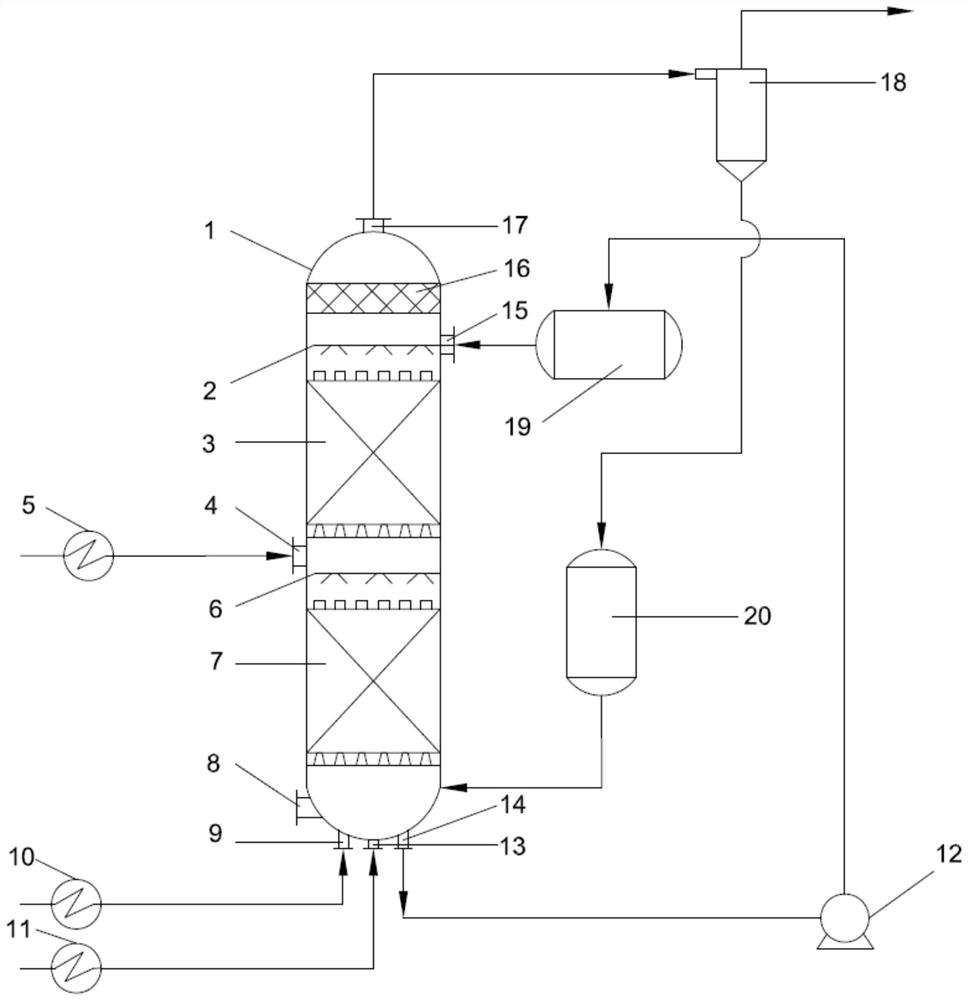

A technology for the synthesis of monochloromethane, which is applied in the direction of feeding devices, chemical methods for reacting liquids and gaseous media, chemical methods for reacting gaseous media with gaseous media, etc., and can solve the problem of the maximum The upper limit of gas velocity can be operated, it is difficult to achieve a large conversion rate of reactants, and the production capacity cannot be improved, so as to achieve the effect of improving the conversion rate of hydrochloric acid, high gas-liquid mass transfer efficiency, and reducing the amount of by-products produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In the packed column of the present invention, the molar ratio of methanol and hydrogen chloride fed from the hydrogen chloride feed port 9 and the fresh methanol vapor feed port 13 at the bottom of the tower kettle is 1:1. The methanol side line feed below the upper filler, the molar ratio of the amount of methanol feed to the HCl fed from the bottom of the tower kettle is 0.1:1, with 75% ZnCl 2 The aqueous solution is the catalyst, the reaction pressure is 0.13Mpag, the reaction temperature is controlled between 150-160°C, the superficial gas velocity in the tower is 80cm / s, and the HCl conversion rate is 98%. After the reaction system is stable, the gas phase product generated at the top outlet of the tower is cooled to 15-25° C., and the liquid phase composition and the uncondensed gas phase composition after cooling and washing are measured. Wherein the acid concentration in the liquid phase composition is 2.84%, the methanol content is 3.88%; the dimethyl ether co...

Embodiment 2

[0057] In the packed column of the present invention, the molar ratio of methanol and hydrogen chloride fed from the hydrogen chloride feed port 9 and the fresh methanol vapor feed port 13 at the bottom of the tower kettle is 1:1. The methanol side line feed below the upper packing, the molar ratio of the methanol feed to the HCl fed from the bottom of the tower kettle is 0.1:1, the catalyst-free process is adopted, the pressure at the top of the reactor is controlled at 0.40-0.42MPag, and the reaction temperature is controlled at 130 ~140°C, the superficial gas velocity in the tower is 30cm / s, and the conversion rate of hydrogen chloride is 99%. After the reaction system is stable, the gas phase product generated at the top outlet of the tower is cooled to 15-25° C., and the liquid phase composition and the uncondensed gas phase composition after cooling and washing are measured. Wherein the acid concentration in the liquid phase composition is 1.97%, the methanol content is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com