Flue gas recirculation nozzle device for preventing boiler water cooling wall from slagging and abrasion

A technology of flue gas recirculation and nozzle device, applied in the field of coal-fired boilers, can solve problems such as water-cooled wall slag formation, and achieve the effects of expanding the cooling area, good protection effect, and improving the area of flue gas diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

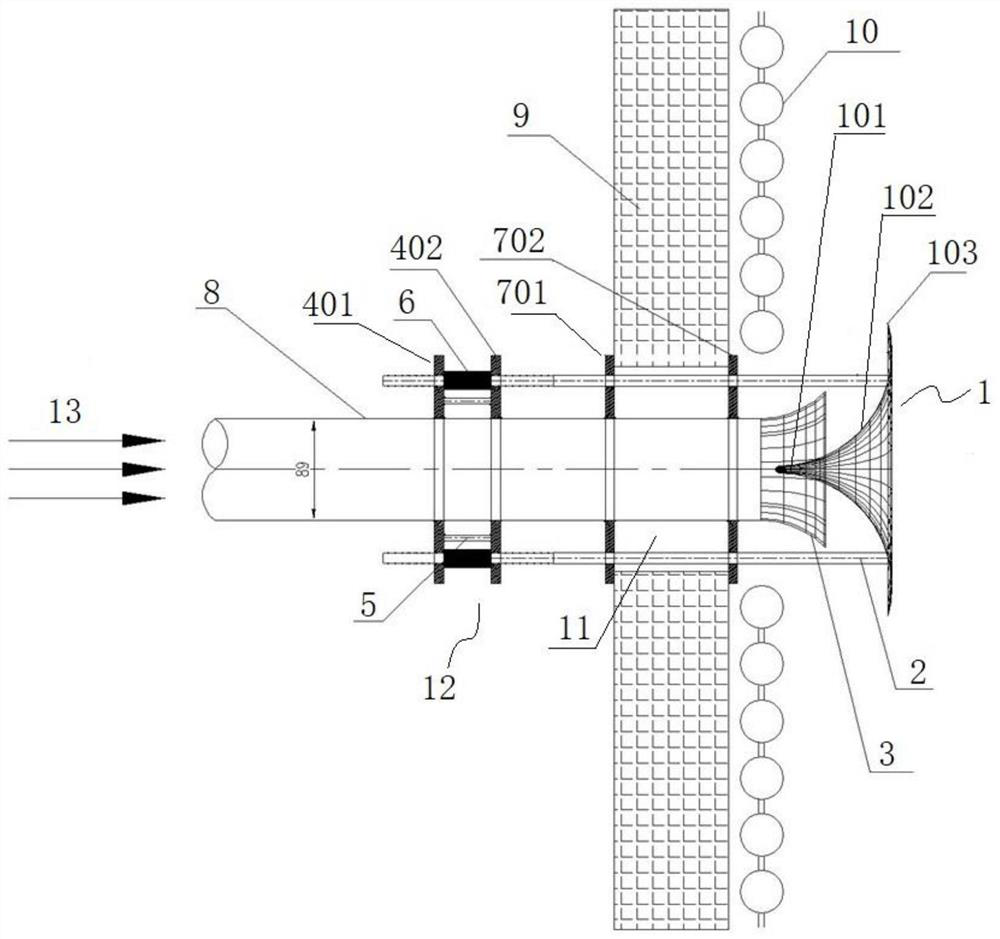

[0018] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the examples. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0019] A flue gas recirculation nozzle device for preventing boiler water walls from slagging and abrasion, comprising a flue pipe 8, the smoke outlet end of the flue pipe 8 extends through the furnace wall 9 and extends into the furnace, and the smoke outlet end of the flue pipe 8 is set There is a smoke pipe flaring 3, and a wind cap 1 is arranged at the 3 place of the smoke pipe flaring.

[0020] The recirculated flue gas enters through the flue pipe 8, and enters the furnace through the flue pipe flare 3. Under the influence of the flue pipe flare 3 with a radian, the flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com