Constant-pressure water supply device and constant-pressure water supply method for concrete dry mixing plant

A technology of dry mixing and constant pressure water supply, applied in the configuration of water supply devices, water supply devices, and water supply pools, etc., can solve the problems of low powder batching accuracy, time-consuming, and water supply metering efficiency needs to be improved, so as to reduce the total time. , Avoid the influence of acceleration on measurement, and improve the effect of water supply accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

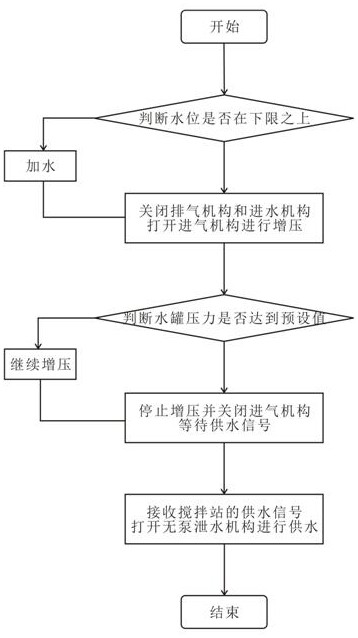

[0029] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

[0030] like Figure 1-3 As shown, this embodiment provides a constant pressure water supply device for a concrete dry mixing plant, including a water tank 10, a pumpless water discharge mechanism 30, an air intake mechanism 20, a water intake mechanism, and an exhaust mechanism. The air intake mechanism 20 is connected to the top of the water tank 10 to provide a constant water supply pressure to the inside of the water tank 10, the pumpless drain mechanism 30 is connected to the bottom of the water tank 10 to supply water to the outside, and the water inlet mechanism is connected to The upper part of the water tank 10 is used to add water to the water tank 10 , and the exhaust mechanism is connected to the top of the water tank 10 to remove the gas inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com