Preparation method of bamboo-based hybrid fiber felt for VARTM molding composite material

A technology of hybrid fibers and composite materials, which is applied in the field of fiber mats, can solve the problems of reduced strength of plant fiber composite materials, inability to disperse fibers uniformly, and reduced service life, so as to achieve the goal of protecting excellent performance, improving interface bonding ability, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the VARTM molding composite material of the present embodiment is with bamboo-based hybrid fiber felt:

[0031] Step 1. Bamboo fiber sorting: put bamboo fibers with a length of 1cm-10cm into distilled aqueous solution and stir at a stirring rate of 300r / min until the bamboo fibers are dispersed. After standing for 1 hour, remove the short and undispersed bamboo fibers in the upper layer , to obtain a length of 1.2cm-7.5cm and a diameter of 0.13mm-0.55mm;

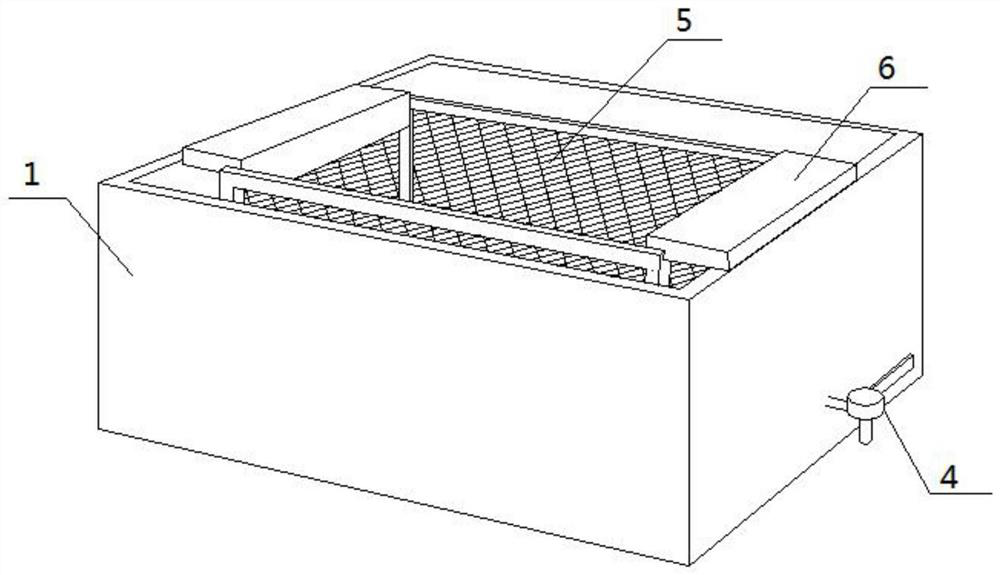

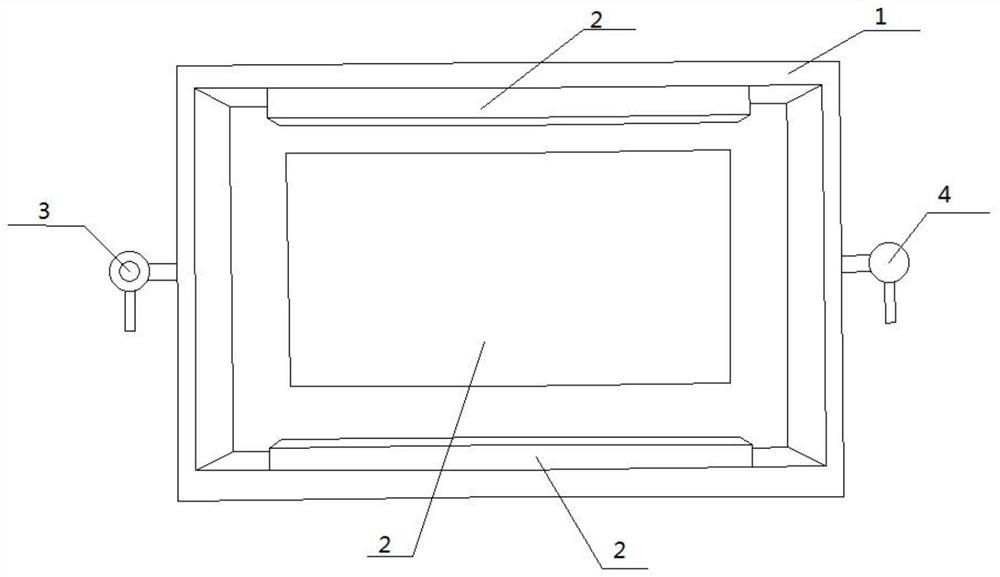

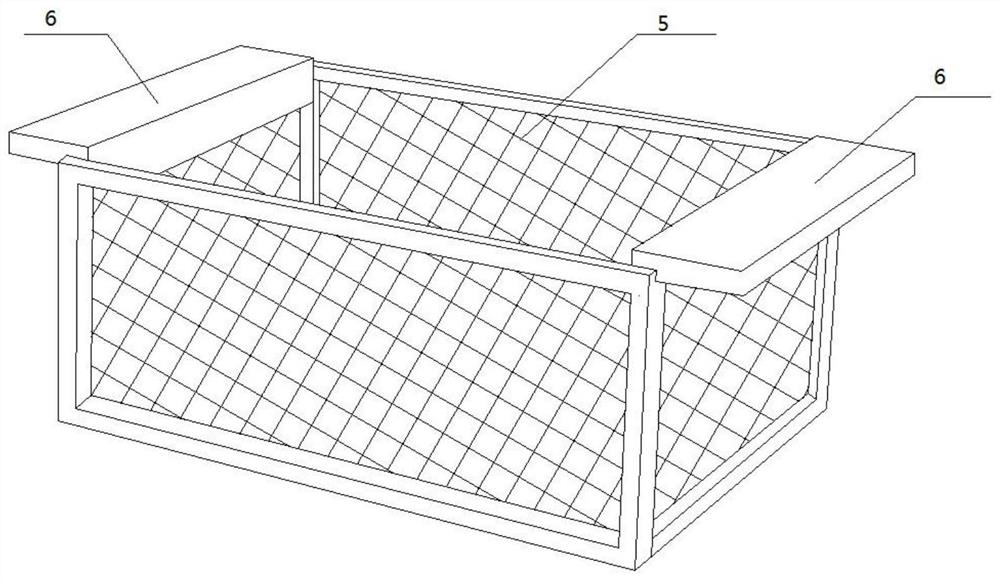

[0032] Step 2, bamboo fiber wet dispersion: uniformly disperse the bamboo fiber of the specifications obtained in step 1 in the filter screen, immerse the filter screen in a wet layer laying device equipped with petroleum ether solvent and suspend it, and ultrasonically vibrate for 10 minutes;

[0033] Step 3, fiber ultrasonic miscibility: add jute fiber to the sieve after the ultrasonic oscillation ends in step 2, the addition of jute fiber is 20% of the quality of the bamboo fiber of the sp...

Embodiment 2

[0040] The preparation method of the VARTM molding composite material of the present embodiment is with bamboo-based hybrid fiber felt:

[0041]Step 1. Bamboo fiber sorting: Put bamboo fibers with a length of 1cm-10cm into distilled aqueous solution and stir at a stirring rate of 400r / min until the bamboo fibers are dispersed. After standing for 2 hours, remove the short and undispersed bamboo fibers in the upper layer , to obtain the standard bamboo fiber with a length of 1.2cm-7.5cm and a diameter of 0.13mm-0.55mm;

[0042] Step 2. Bamboo fiber wet dispersion: uniformly disperse the bamboo fiber of the specifications obtained in step 1 in the filter screen, immerse the filter screen in a wet layer laying device equipped with a silane coupling agent and a mixed solvent of water to suspend, and oscillate ultrasonically for 20 minutes ; An ultrasonic device is installed in the wet laying device; the mass ratio of water to the silane coupling agent in the mixture of the silane c...

Embodiment 3

[0049] The preparation method of a kind of VARTM forming composite material with bamboo-based hybrid fiber mat of the present embodiment is:

[0050] Step 1. Bamboo fiber sorting: put bamboo fibers with a length of 1cm-10cm into distilled aqueous solution and stir at a stirring rate of 500r / min until the bamboo fibers are dispersed. After standing for 3 hours, remove the short and undispersed bamboo fibers in the upper layer , to obtain the standard bamboo fiber with a length of 1.2cm-7.5cm and a diameter of 0.13mm-0.55mm;

[0051] Step 2. Bamboo fiber wet dispersion: uniformly disperse the bamboo fiber of the specifications obtained in step 1 in the filter screen, immerse the filter screen in a wet layer laying device equipped with a mixed solvent of silane coupling agent and ethanol to suspend, and oscillate ultrasonically for 30 minutes , an ultrasonic device is installed in the wet laying device; the mass ratio of ethanol to the silane coupling agent in the mixture of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com