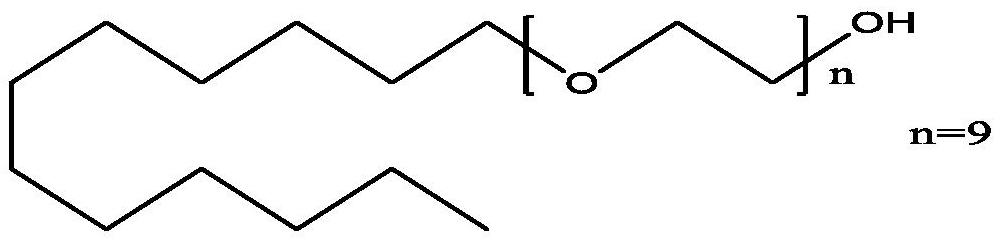

Refining process of laurinol and process for preparing lauromacrogol by using refined product as raw material

A technology of lauryl alcohol and refined products, which is applied in the field of medicine and chemical industry, can solve problems such as poor stability, and achieve the effects of improving stability, reducing moisture, and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation of embodiment 1 lauryl alcohol refined product 1

[0052] 1) Add 1 kg of lauryl alcohol raw material, 1 kg of tetrahydrofuran and 1 kg of acetonitrile into the reaction vessel, raise the temperature to about 28° C., and stir until completely dissolved to obtain a reaction solution. 2) Cool the reaction solution to 0° C., stir and crystallize for 30 minutes, filter with suction, collect the filter cake, and obtain the intermediate white solid. 3) Put the intermediate white solid into a reaction vessel, slowly raise the temperature to 40°C, stir until it melts, distill under reduced pressure after complete melting, evaporate the residual organic solvent in the system, collect the distillation product, gradually raise the temperature to 90°C, and control The vacuum degree was -0.1MPa, and the vacuum distillation was carried out for 4 hours to obtain the remaining product, which was the refined product of lauryl alcohol 1.

[0053] The lauryl alcohol refine...

Embodiment 2

[0056] The preparation of embodiment 2 lauryl alcohol refined product 2

[0057] 1) Add 5 kg of lauryl alcohol (raw material), 5 kg of tetrahydrofuran and 5 kg of acetonitrile into a reaction vessel, raise the temperature to about 25° C., stir to completely dissolve, and obtain a reaction solution. 2) Cool the reaction solution to -2°C, stir and crystallize for 20 minutes, filter with suction, collect the filter cake, and obtain the intermediate white solid. 3) Put the intermediate white solid into the reaction vessel, slowly raise the temperature to 20°C, stir until it melts, distill under reduced pressure after complete melting, distill off the residual organic solvent in the system, collect the distillation product, and gradually raise the temperature to 80°C, Control the vacuum degree to ≤-0.1MPa, and distill under reduced pressure for 5 hours to obtain the remaining product, which is the refined product of lauryl alcohol 2.

[0058] The refined lauryl alcohol product 2 p...

Embodiment 3

[0061] The preparation of embodiment 3 lauryl alcohol refined product 3

[0062] 1) Add 10kg lauryl alcohol (raw material), 10kg tetrahydrofuran and 20kg toluene to the reaction vessel, raise the temperature to 30°C, stir to dissolve completely, and obtain the reaction solution; 2) Cool the reaction solution to -1°C, stir and crystallize for 30min, and filter with suction , the filter cake was collected to obtain the intermediate white solid. 3) Put the white solid of the intermediate into the reaction vessel, slowly raise the temperature to 40°C, stir and melt, and distill under reduced pressure after complete melting, collect the distillation product, gradually raise the temperature to 70°C, control the vacuum degree ≤ -0.1MPa, and distill under reduced pressure for 6h , to obtain the remaining product, which is the refined product of lauryl alcohol 3. The refined lauryl alcohol product 3 prepared in Example 3 was tested according to the requirements for related substances ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com