A uasb reactor system with self-heating function

A reactor system and reactor technology, applied in chemical instruments and methods, biological water/sewage treatment, water treatment parameter control, etc. The effect of good thermal insulation effect and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

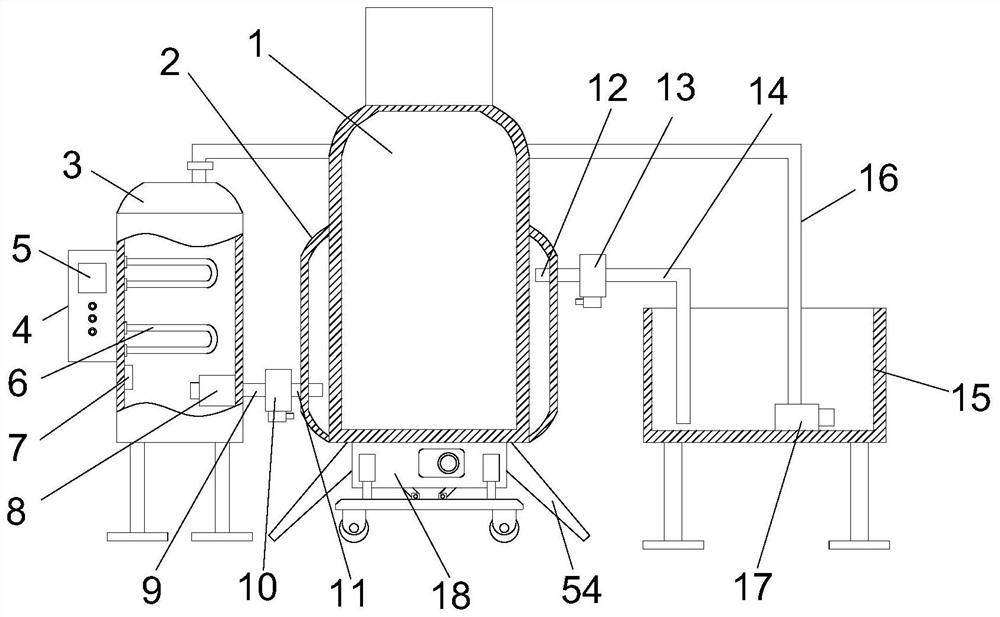

[0032] refer to Figure 1-7 , a UASB reactor system with self-heating function, including a UASB reactor body 1, a hot water jacket 2, an electric heating tank 3 and a cold water collection tank 15, and the hot water jacket 2 is fixedly coated on the UASB reactor body 1 The electric heating tank 3 and the cold water collection tank 15 are located on both sides of the UASB reactor body 1 respectively, the bottom end of the UASB reactor body 1 is fixedly connected with a support leg 54, and the UASB reactor body 1 and the hot water jacket 2 There is a cold water conduction mechanism connected between the hot water jacket 2 and the cold water collection tank 15. A return pipe 16 is also provided between the electric heating tank 3 and the cold water collection tank 15. One end of the return pipe 16 is connected to the cold water collection tank 15. The top of the electric heating tank 3 is connected, and the other end of the return pipe 16 extends into the cold water collection t...

Embodiment 2

[0034] refer to Figure 1-7 The difference between this embodiment and Embodiment 1 is that the hot water conduction mechanism includes a hot water inlet pipe A9, a hot water inlet pipe B11 and a first water flow regulating mechanism 10, and the hot water inlet pipe A9 is connected to the electric heating tank 3 close to the UASB reaction One side of the device body 1, the hot water inlet pipe B11 is connected to the side of the hot water jacket 2 close to the electric heating tank 3, one end of the hot water inlet pipe B11 extends into the hot water jacket 2, and the hot water inlet pipe B11 The other end is fixedly connected with the first water flow regulating mechanism 10, and one end of the hot water inlet pipe A9 extends into the electric heating tank 3 and is connected with the second water pump 8, and the other end of the hot water inlet pipe A9 can be connected with the first water flow regulating mechanism 10. After the connection is disassembled, the hot water in th...

Embodiment 3

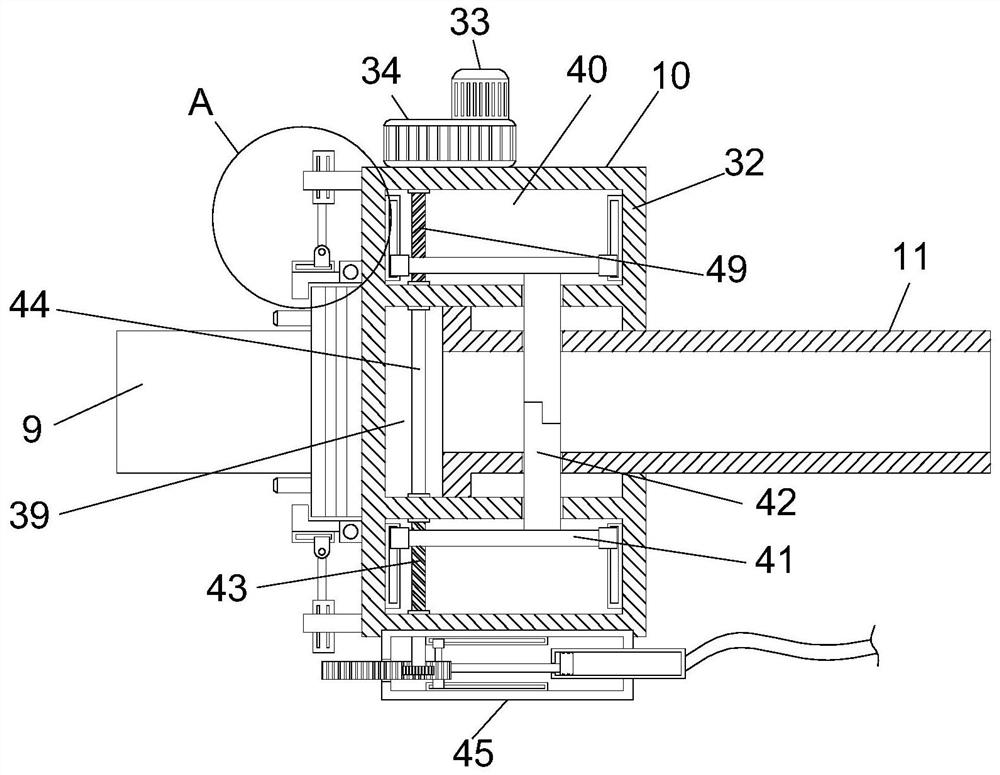

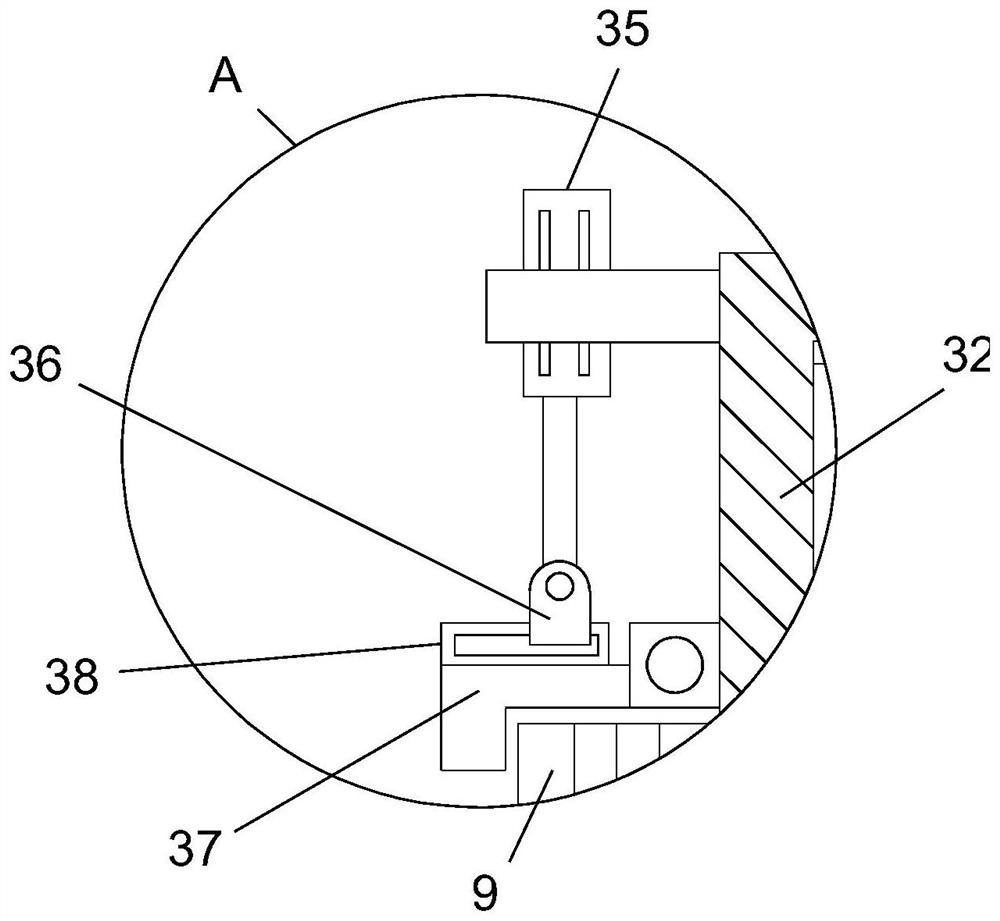

[0037] refer to Figure 1-7 The difference between this embodiment and Embodiment 1 is that the first water flow regulating mechanism 10 and the second water flow regulating mechanism 13 include a casing 32, and a first installation cavity 39 is opened on the casing 32, and the first installation cavity 39 is located on the casing 32. The top and bottom of the chamber 39 are provided with a second installation chamber 40, one end of the hot water inlet pipe B11 and the cold water discharge pipe B14 extends into the second installation chamber 40, and the two second installation chambers 40 are respectively rotatably installed with first The threaded rod 43 and the second threaded rod 49, the first mounting cavity 39 is rotatably equipped with a connecting rod 44, the top of the connecting rod 44 is fixedly connected with the second threaded rod 49, and the bottom end of the connecting rod 44 is connected with the first threaded rod 43 , the outer sides of the first threaded ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com