An alkaline battery production line and a production process thereof

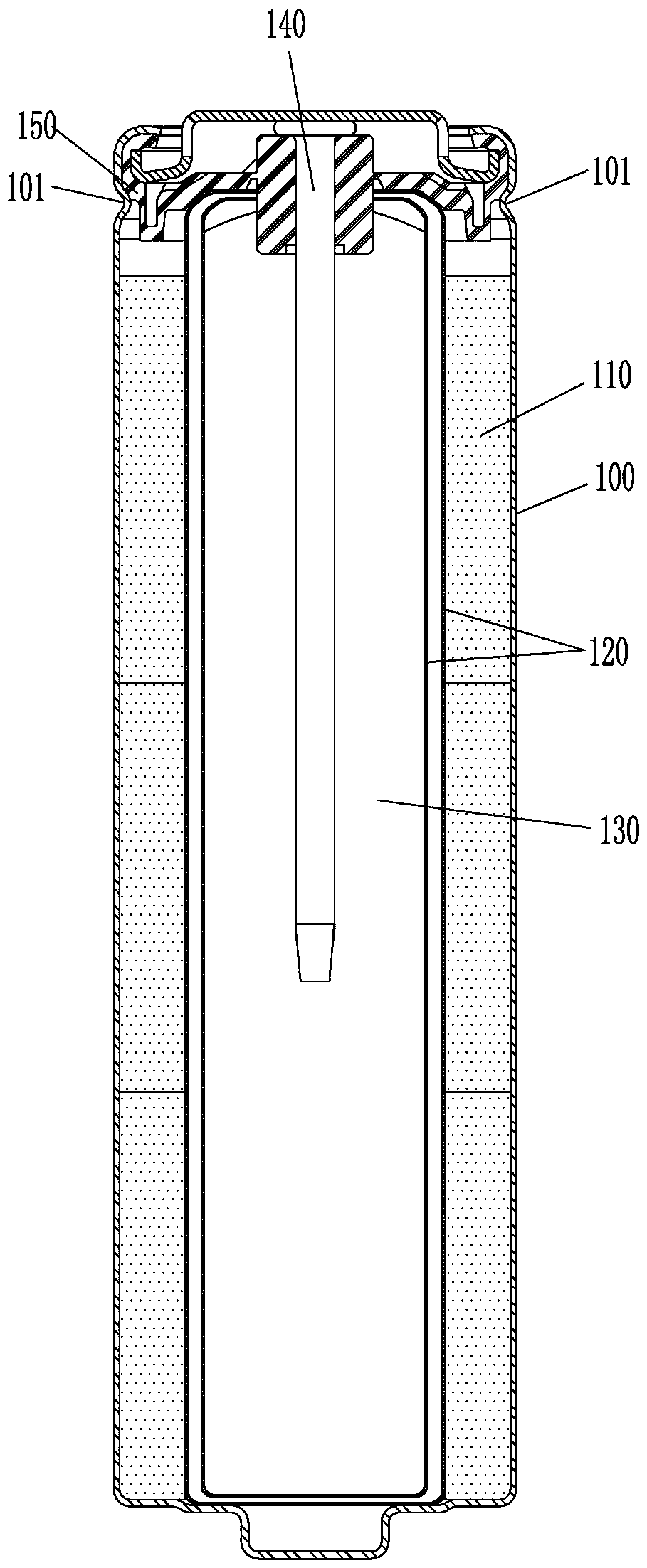

An alkaline battery and production line technology, which is applied in the field of battery manufacturing, can solve the problems that the comprehensive electrical performance of alkaline batteries cannot be achieved, the positive electrode ring 110 is broken, and the battery steel shell 100 is deformed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

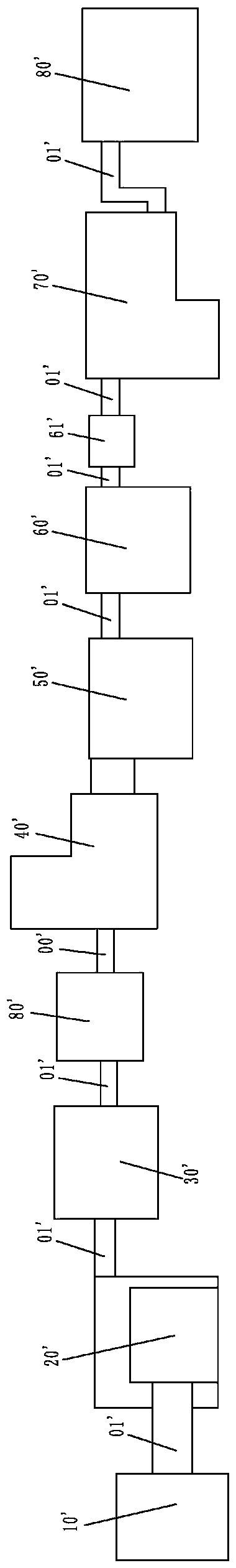

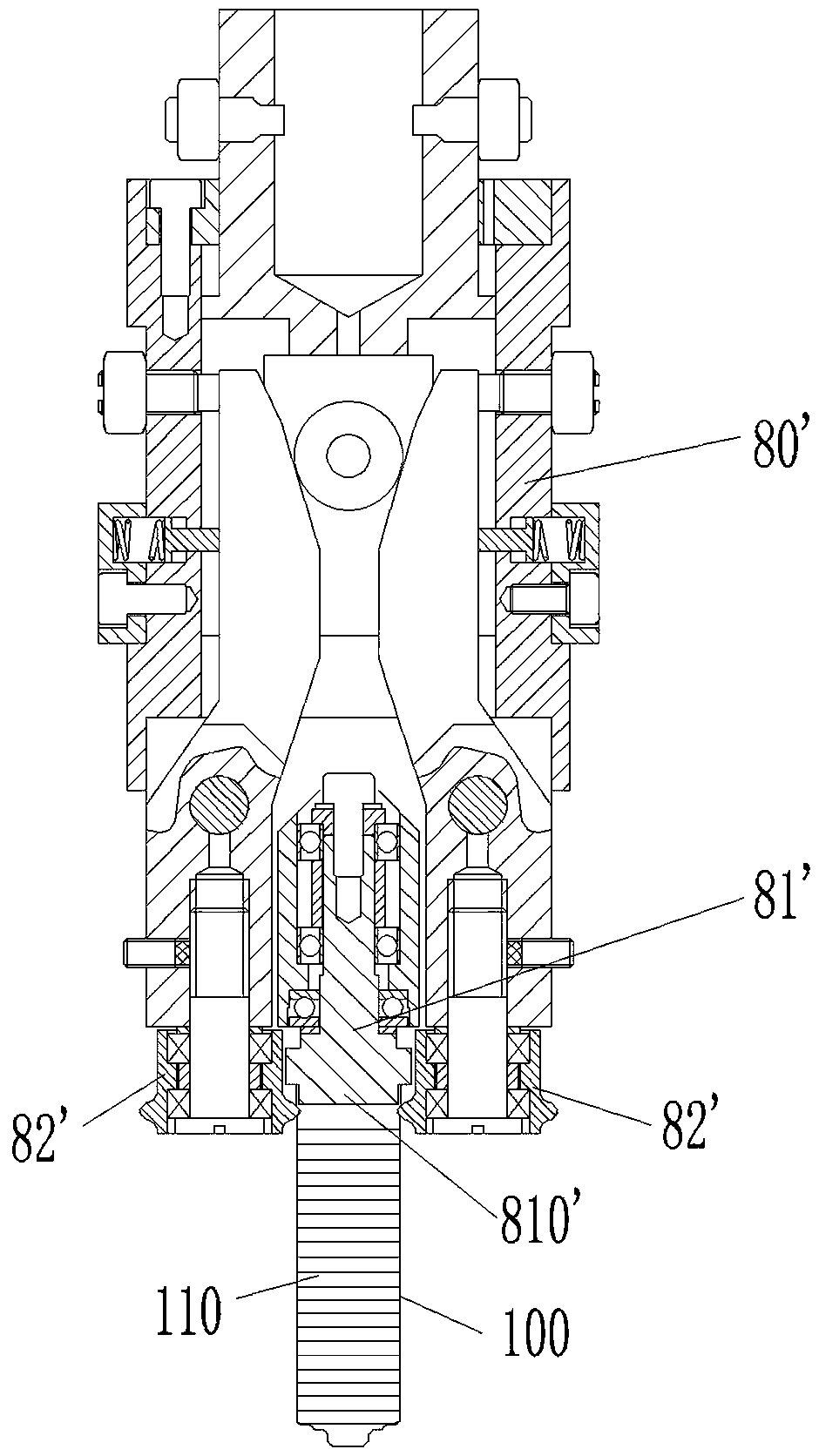

[0019] Combine Figure 4 ~ Figure 6 , An alkaline battery production line, including battery steel shell hopper 10, battery steel shell conveying turntable 20, positive ring inserting machine 30, sealant coating machine 40, isolating tube inserting machine 50, electrolysis The liquid injection machine 60, the electrolyte absorption machine 61, the negative electrode material injection machine 70, and the wire binding machine 80 are all connected to each other through the battery steel shell conveying track 01, and the wire binding machine 80 is connected to the sealing machine 90; The wire binding machine 80 includes a wire binding head 81. The surface of the wire binding head 81 is provided with a limiting slot 810 into which the open end of the battery steel shell 100 is inserted. During operation, the open end of the battery steel shell 100 is inserted into the limiting slot 810 to realize the battery steel shell. To fix 100 on the wire tie head 81, the wire tie wheels 82 lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com