Washing method for removing residual alkali on surface of positive electrode material

A washing method and positive electrode material technology, applied in the direction of liquid cleaning method, positive electrode, cleaning method and utensils, etc., can solve the problems of water residue, achieve the effect of reducing surface phase change and avoiding water residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

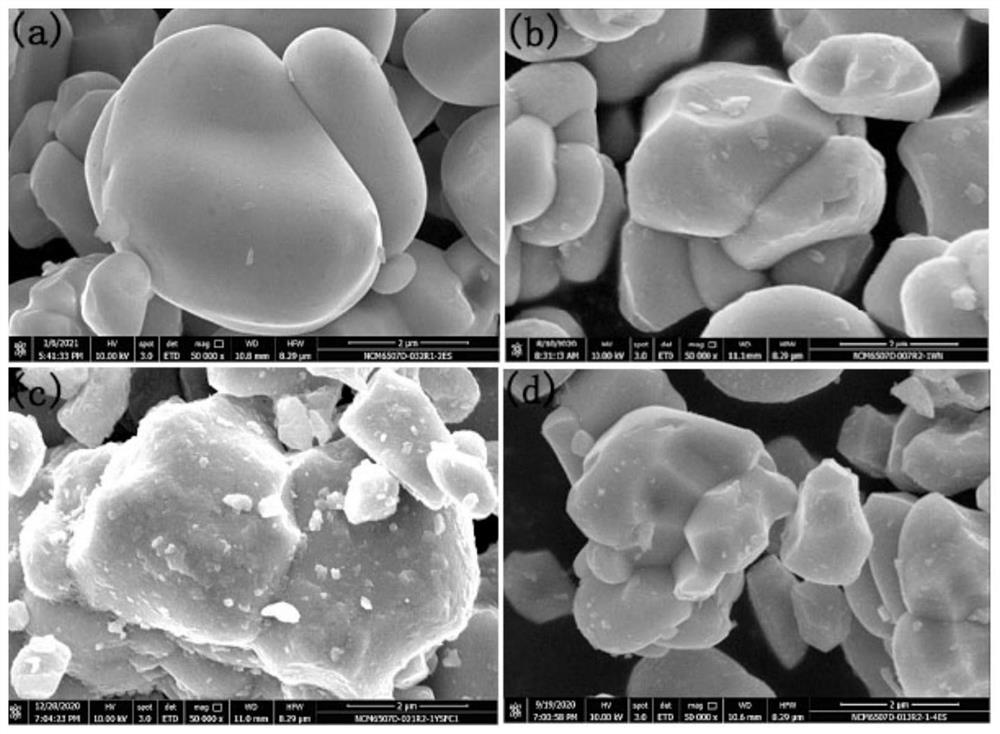

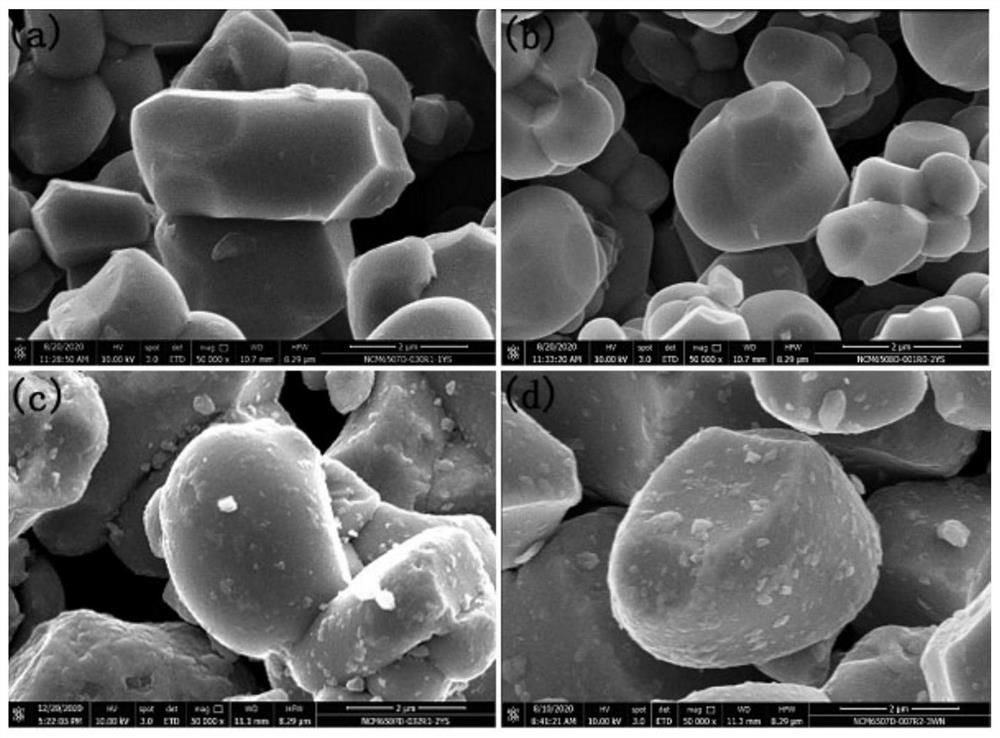

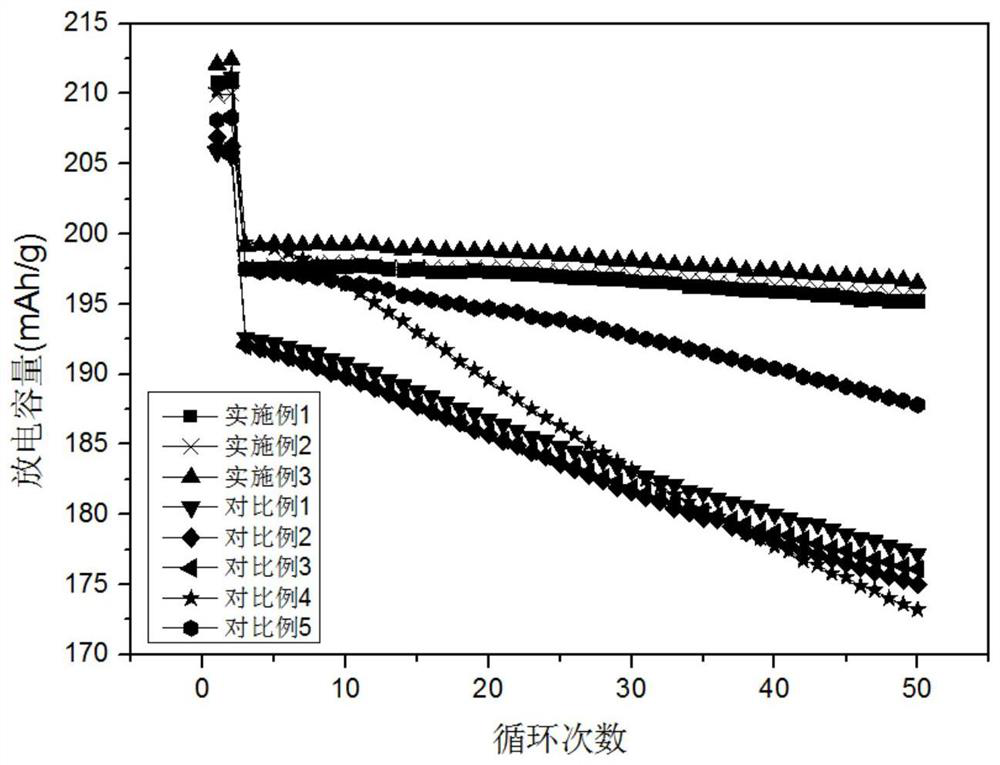

Embodiment 1

[0026] (1) Mix 1000g of carbon disulfide with 1000g of water and disperse evenly under the action of an external ultrasonic wave to obtain a mixed solution; wherein, the ultrasonic power is 50Hz, the speed of the disperser is 1000r / min, the dispersion time is 10min, and the temperature of the dispersion is 25°C;

[0027] (2) 2000g unwashed ternary material LiNi 0.8 co 0.1 mn 0.1 o 2 Add it to the above mixed solution, wash it under the stirring condition of a high-speed disperser, after the washing is completed, let it stand at 25°C for stratification, then remove the water phase with the residual alkali dissolved in the upper layer, filter and separate the ternary material and carbon disulfide, and finally The filtered ternary material is vacuum-dried to obtain the ternary material after removing the residual alkali on the surface. Among them, the speed of the high-speed disperser is 1000r / min, the time is 10min, the temperature of the washing liquid is 25°C; the temperatu...

Embodiment 2

[0029] (1) Mix 500g of carbon disulfide with 1000g of water and disperse evenly under the action of an external ultrasonic wave to obtain a mixed solution; wherein, the ultrasonic power is 50Hz, the speed of the disperser is 1000r / min, the dispersion time is 20min, and the temperature of the dispersion is 25°C;

[0030] (2) 4500g unwashed ternary material LiNi 0.8 co 0.1 mn 0.1 o 2Add it to the above mixed solution, wash it under the stirring condition of a high-speed disperser, after the washing is completed, let it stand at 25°C for stratification, then remove the water phase with the residual alkali dissolved in the upper layer, filter and separate the ternary material and carbon disulfide, and finally The filtered ternary material is vacuum-dried to obtain the ternary material after removing the residual alkali on the surface. Among them, the speed of the disperser is 1000r / min, the time is 10min, the temperature of the washing liquid is 60°C; the temperature of the vac...

Embodiment 3

[0032] (1) Mix 100g of 1,4-dichlorobenzene with 1000g of water and disperse evenly under the action of an external ultrasonic wave to obtain a mixed solution; wherein, the ultrasonic power is 50Hz, the speed of the disperser is 1000r / min, the dispersion time is 10min, and the temperature of the dispersion is 60°C ;

[0033] (2) 2200g unwashed ternary material LiNi 0.8 co 0.1 mn 0.1 o 2 Add it to the above mixed liquid, wash it under the condition of stirring in a high-speed disperser, after washing, let it stand at 60°C for stratification, then remove the water phase in which the residual alkali is dissolved in the upper layer, and mix the ternary material and 1,4-bis The chlorobenzene is separated by filtration, and finally the filtered ternary material is vacuum-dried to obtain the ternary material after removing the residual alkali on the surface. Among them, the speed of the high-speed disperser is 1000r / min, the time is 10min, the temperature of the washing liquid is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com