A method of manufacturing a pcb

A production method and solder mask technology, applied in the direction of electrical connection of printed components, printed circuit components, printed circuits, etc., can solve problems such as failure, pin corrosion, etc., and achieve the effect of preventing the residue of potion or water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

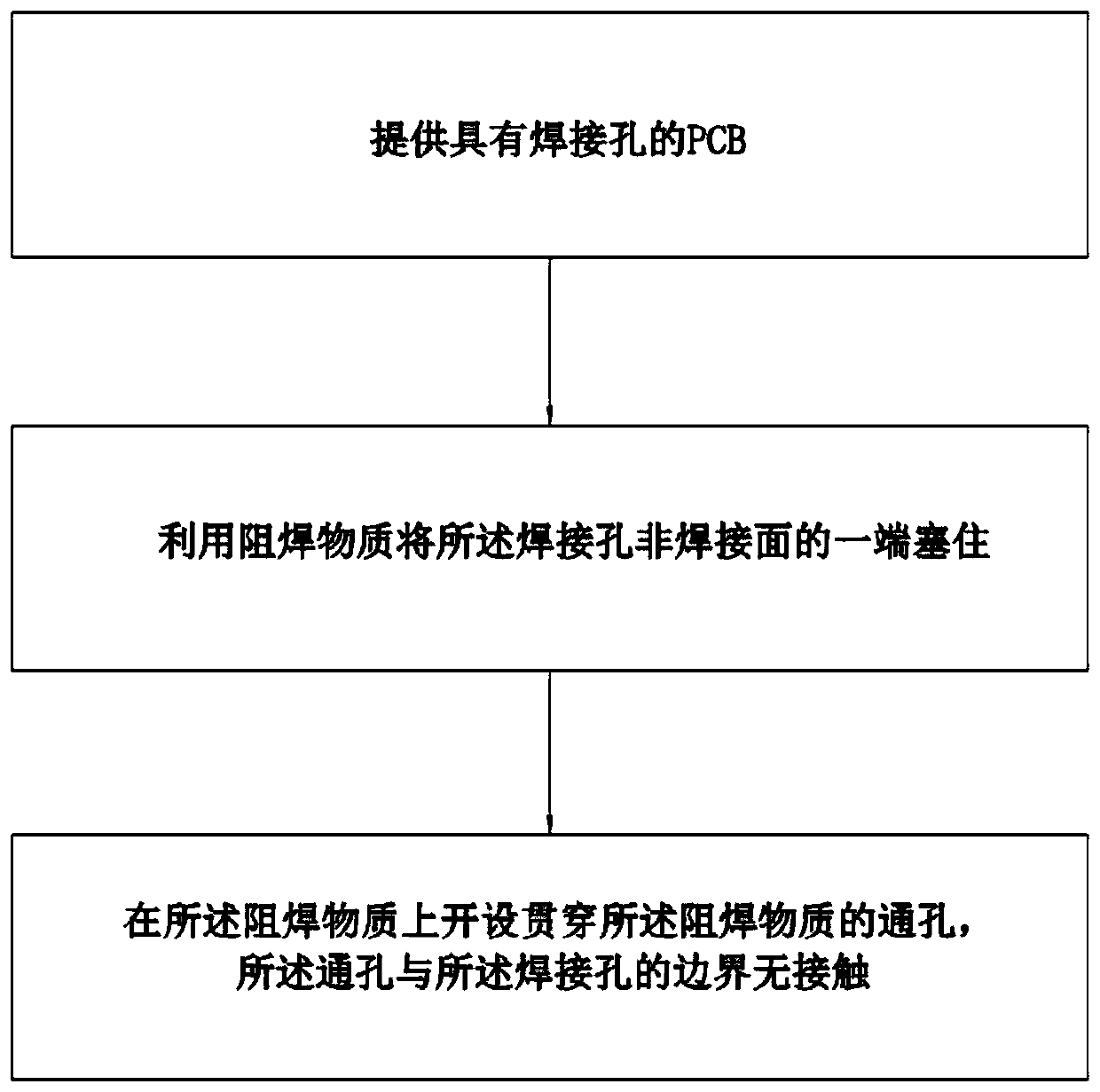

[0062] Such as figure 1 , 3 , 6 and 7, the present embodiment provides a method for manufacturing a PCB, comprising the following steps:

[0063] Step 1, providing PCB1 with soldering holes 11;

[0064] Step 2, using a solder resist material to plug one end of the non-welding surface of the welding hole 11;

[0065] Step 3, opening a through hole penetrating through the solder resist material on the solder resist material, and the through hole has no contact with the boundary of the solder hole 11 .

[0066] Specifically, after the welding hole 11 is plugged with a solder resist material, a through hole through the solder resist material is opened, and at the same time, the through hole does not overlap with the boundary of the welding hole 11, and the solder resist material completely surrounds the inner wall of the solder hole 11 to form a solder resist Ring 4, so when welding components or connectors on PCB1, the solder is blocked by the solder resist ring 4 during the c...

Embodiment 2

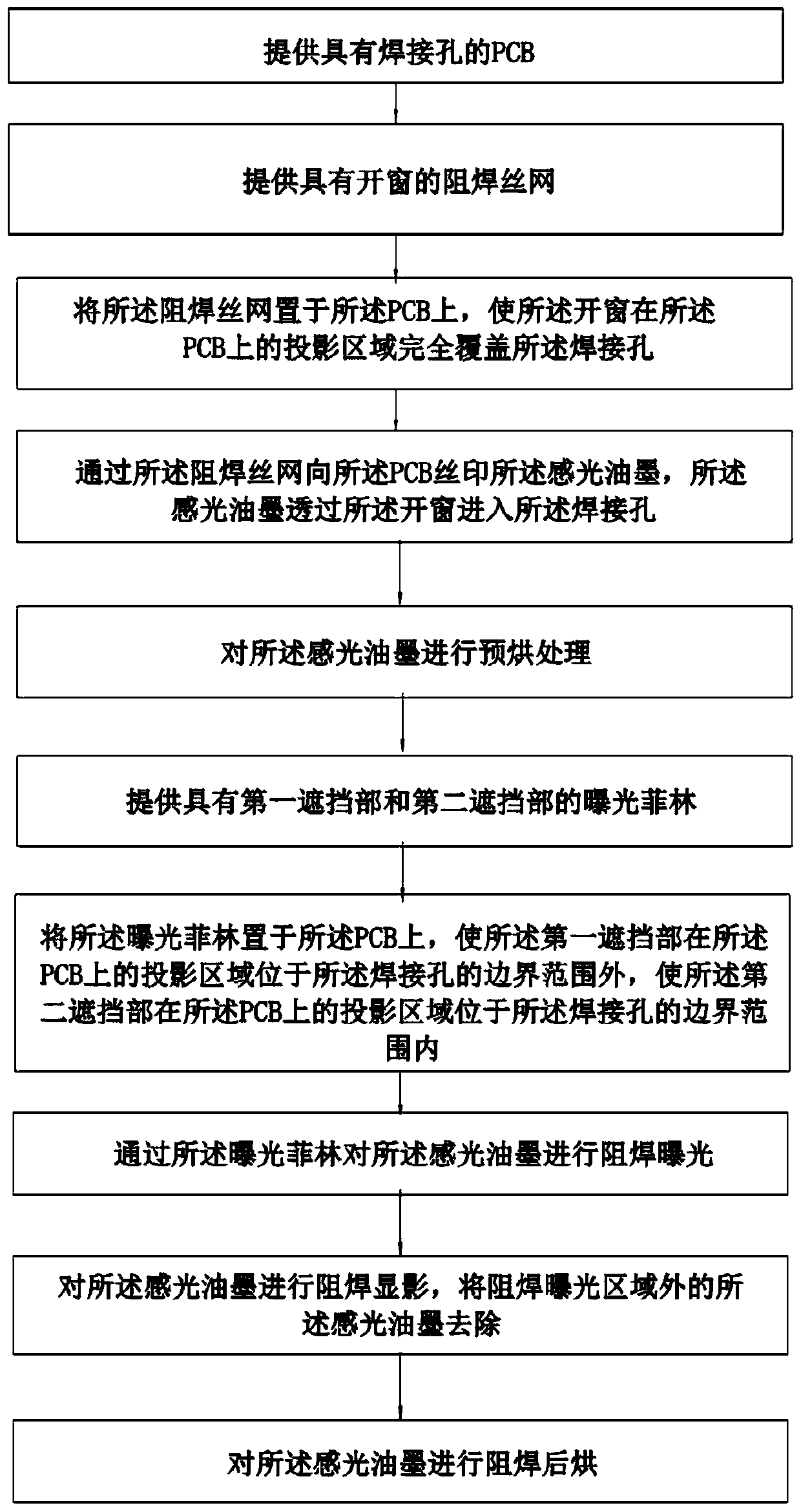

[0069] Such as Figure 2-7 As shown, the present embodiment provides a method for manufacturing a PCB, comprising the following steps:

[0070] Step 1, providing a PCB 1 with soldering holes 11 .

[0071] The aforementioned PCB1 with soldering holes 11 can be the PCB1 in any state before the PCB1 is finished. The welding holes 11 can also be equivalently replaced with welding slots.

[0072] Step 2, providing the solder resist wire mesh 3 with windows 31 .

[0073] The material of the solder resist screen 3 is metal or polymer fiber, but not limited to the above materials.

[0074] Step 3, placing the solder resist screen 3 on the PCB 1 so that the projected area of the window 31 on the PCB 1 completely covers the solder hole 11 .

[0075] Step 4: Screen printing the photosensitive ink on the PCB 1 through the solder resist screen 3 , and the photosensitive ink enters the soldering hole 11 through the window 31 .

[0076] The projected area of the window 31 on the PCB...

Embodiment 3

[0097] Such as Figure 6-7 As shown, a PCB, the PCB1 is provided with a welding hole 11, and the inner wall of the welding hole 11 is provided with a solder resist ring 4, and the material of the solder resist ring 4 is photosensitive ink.

[0098] The solder resist ring 4 surrounds the inner wall of the solder hole 11 , but does not completely block the solder hole 11 (that is, both ends of the solder hole 11 still pass through). When soldering components or connectors on the PCB1, the solder resist ring 4 can prevent the solder from easily climbing up to the other side of the board along the copper surface on the inner wall of the solder hole 11, and at the same time, because the solder resist ring 4 does not completely block the solder hole 11, It also prevents the solder from having liquid medicine or water vapor remaining in the soldering hole 11.

[0099] Further, the height of the solder resist ring 4 is greater than or equal to 0.3 mm.

[0100] The height of the solder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com