Anti-dewing device for inner walls of steel silos

A steel silo and anti-condensation technology, applied in fruit hanging devices, botanical equipment and methods, gardening, etc., can solve the problems of shortening the service life of steel silos, reducing the structure of steel silos, and damaging grain quality, so as to avoid water vapor residue , Prevent condensation, avoid the effect of condensation on the inner wall of the warehouse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

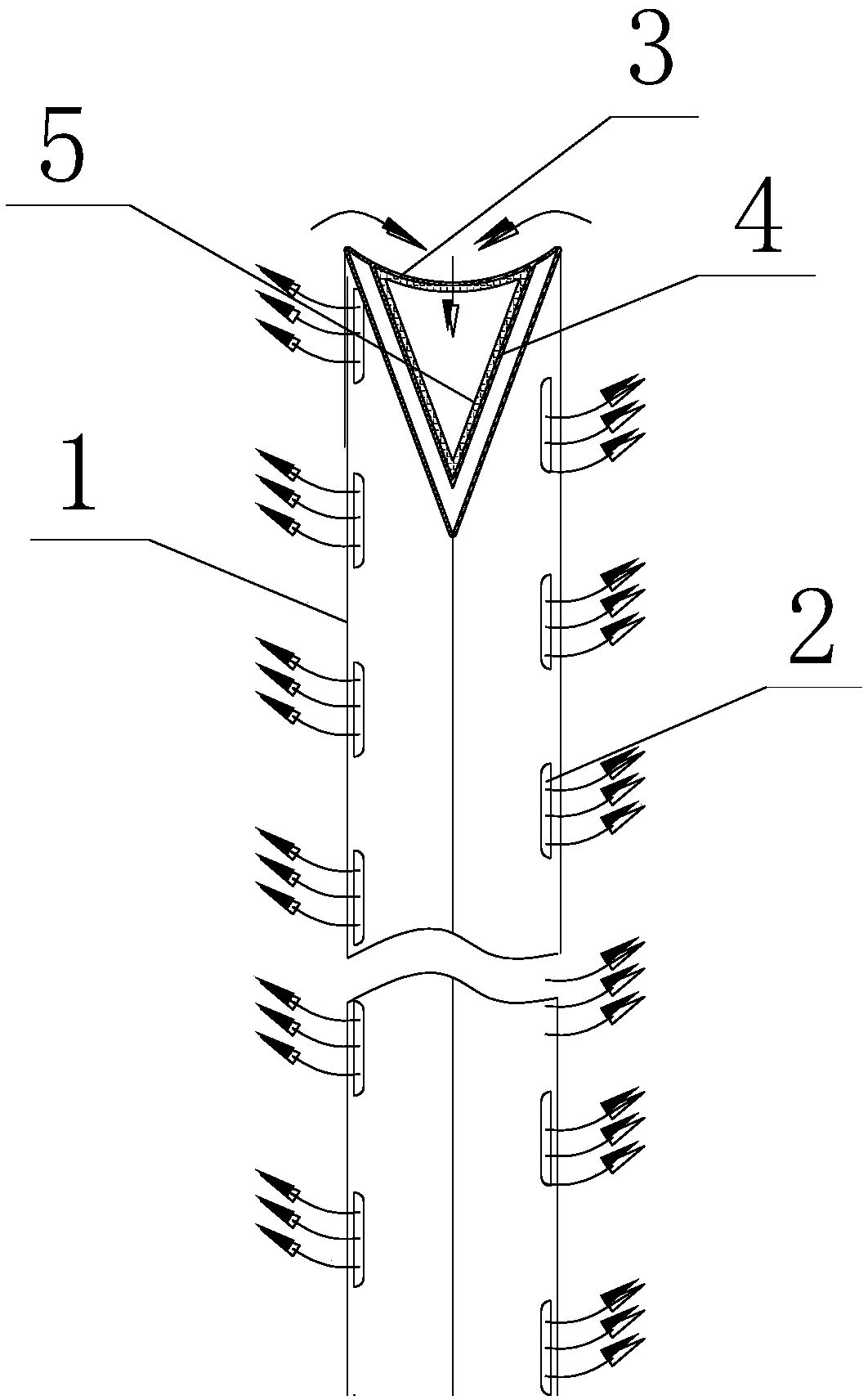

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an anti-condensation device on the inner wall of a steel silo proposed by the present invention.

[0013] refer to figure 1 , a kind of anti-condensation device on the inner wall of the steel silo proposed by the present invention includes: a ventilation pipe 1 for being installed on the side wall of the steel silo and inserting one end into the air distribution room at the bottom of the steel silo, the through-hole pipe 1 has an axial An extended first lumen and an axially extending second lumen, the first lumen is located outside the second lumen, the side wall of the first lumen is provided with a plurality of The dry air is directed to the fish scale hole 2 on the side wall of the steel silo; a negative pressure generator is installed inside the second lumen, and an air intake channel 3 communicating with the outside is provided on the side wall of the second lumen.

[0014] The present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com