Cleaning and processing method for reducing mould breeding of dried fruits

A processing method and technology of dried fruit mold, which is applied in food drying, fruit and vegetable preservation, heating preservation of fruits/vegetables, etc., can solve the problems of affecting the overall sensory condition of materials, difficult to kill, and harmful bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

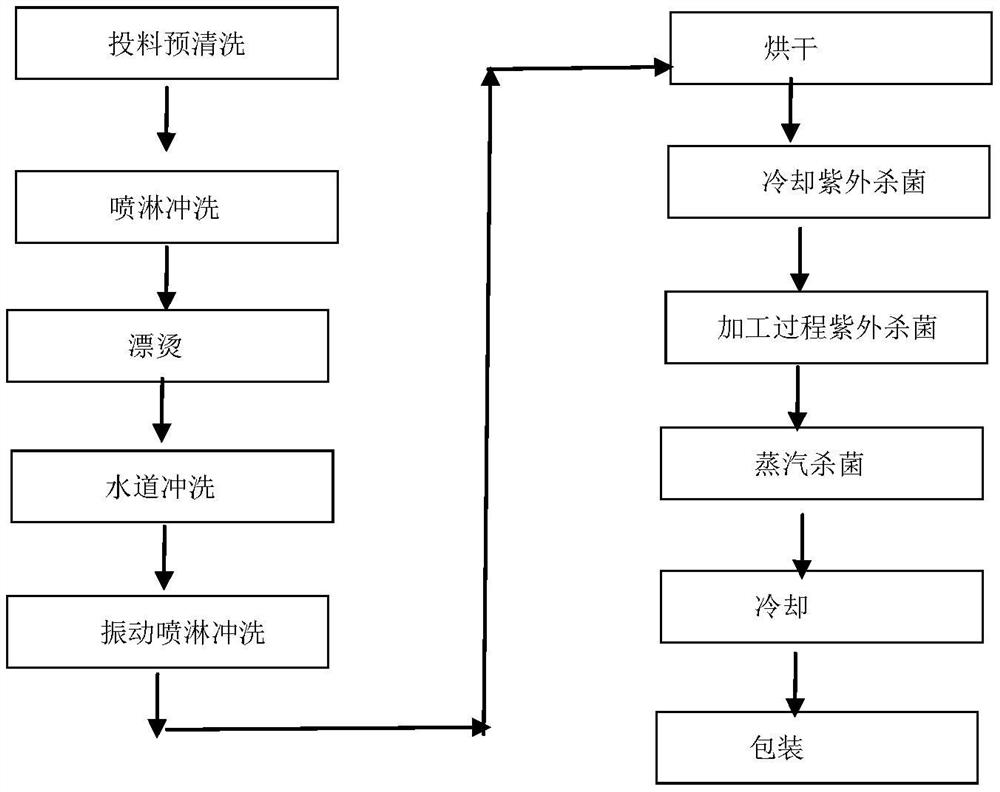

Image

Examples

Embodiment 1

[0038] A cleaning and processing method for reducing the growth of dried fruit mold, characterized in that it comprises the following steps,

[0039] 1) Pre-cleaning: quickly clean the red raisins after feeding, and the time is controlled within 10S;

[0040] 2) Spray and rinse: put the raisins on the vibrating screen to ensure that the raisins are spread flat on the screen, the screen mesh is controlled at 5mm-6mm, and dry with strong wind after spraying;

[0041] 3) Blanching: Put the dried fruit on a uniform and transparent stainless steel mesh belt with a mesh diameter of 2mm-4mm, and move the mesh belt covered with dried fruit in hot water at a constant speed (speed / time controllable), During the blanching process, ozone air is agitated at the bottom of the mesh belt hot water to avoid aggregation and adhesion of dried fruit and even heating;

[0042] 4) Waterway flushing: place the raisins in the waterway cleaning equipment for flushing, use a stepped water flow channel...

Embodiment 2

[0050] A cleaning and processing method for reducing the growth of dried fruit mold, characterized in that it comprises the following steps,

[0051] 1) Pre-cleaning: quickly clean the black currant raisins after feeding, and the time is controlled within 10S;

[0052] 2) Spray and rinse: put the fruit raisins on the vibrating screen to ensure that the raisins are spread flat on the screen, the screen mesh is controlled at 5mm-6mm, and the strong wind is blown to dry after spraying;

[0053] 3) Blanching: Put the dried fruit on a uniform and transparent stainless steel mesh belt with a mesh diameter of 2mm-4mm, and move the mesh belt covered with dried fruit in hot water at a constant speed (speed / time controllable), During the blanching process, ozone air is agitated at the bottom of the hot water on the mesh belt to avoid aggregation and adhesion of dried fruit and even heating;

[0054] 4) Waterway flushing: place the raisins in the waterway cleaning equipment for flushing...

Embodiment 3

[0063] Take the red raisins and black currant raisins prepared by the method of the present invention as embodiment 1 and embodiment 2, and the red raisins and black currant raisins directly purchased on the market as control group 1 and control group 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com