Method for evaluating thickness of water film after water-phase imbibition flowback of gas reservoir rock containing expansive clay

A technology for swelling clay and water film thickness, which is applied in soil material testing, permeability/surface area analysis, and nuclear magnetic resonance analysis, etc. It can solve the influence of rock water phase imbibition and flowback experiments, and can not effectively reflect the pores of reservoir rocks Structural state and other issues to achieve the effects of avoiding hydration, low test cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

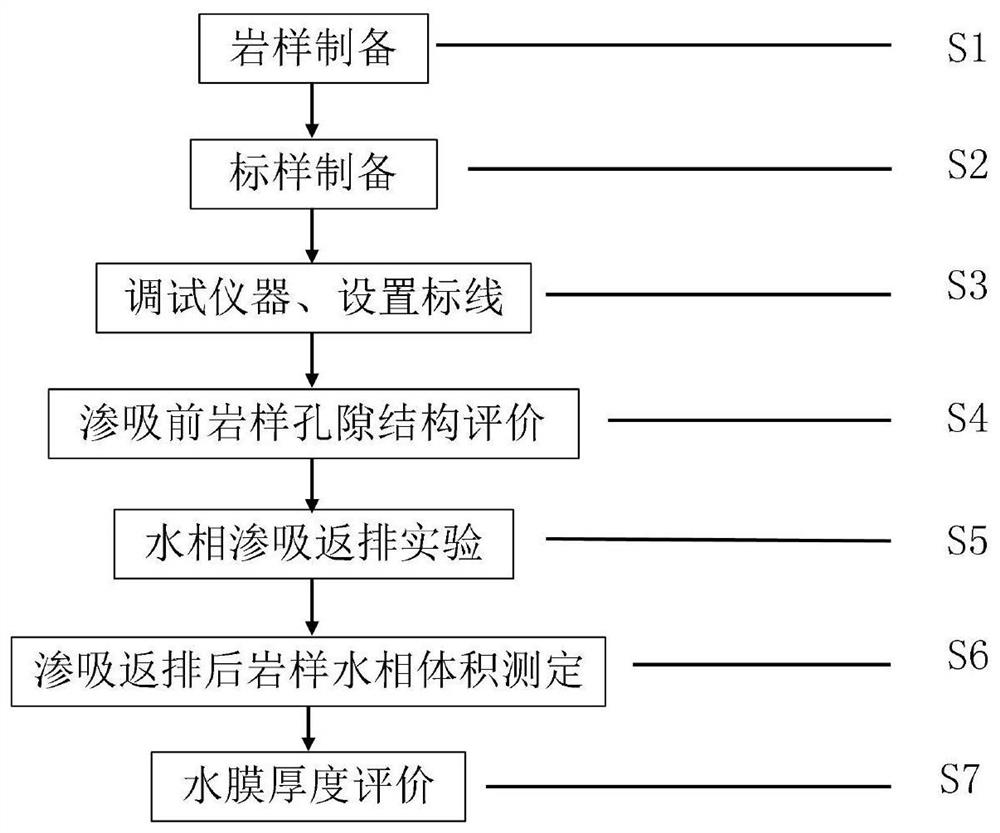

[0036] like figure 1 As shown, the method for evaluating the water film thickness after water-phase imbibition and flowback of rock containing swelling clay gas reservoirs of the present invention comprises the following steps:

[0037] Step S1, drilling shale reservoir rocks, making it into a core sample with a diameter of about 25 mm and a length of about 30 mm; washing the core with oil, salt, and drying, because shale has low porosity and low permeability, and the standard core analysis method is more accu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com