A kind of fabric indigo dyeing method

A dyeing method and indigo technology, applied in the field of textile dyeing and finishing, can solve the problems such as the inability to reach the dark color of fiber penetration, the low dyeing rate and dye uptake rate, and the low fabric affinity, so as to save the foaming link and strengthen the penetration dyeing. effect, the effect of increasing the half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The embodiment of the present application provides a kind of fabric indigo dyeing method, comprises the following steps:

[0076] S1. Add 0.3 g of indigo to 100 mL of water, then add 2 g of Tween 80 and 3 g of absolute ethanol, and ultrasonically disperse to obtain a dispersion;

[0077] S2. Filter the dispersion with a positive pressure filter, and then ultrasonically disperse it again after the filtration to obtain an indigo suspension;

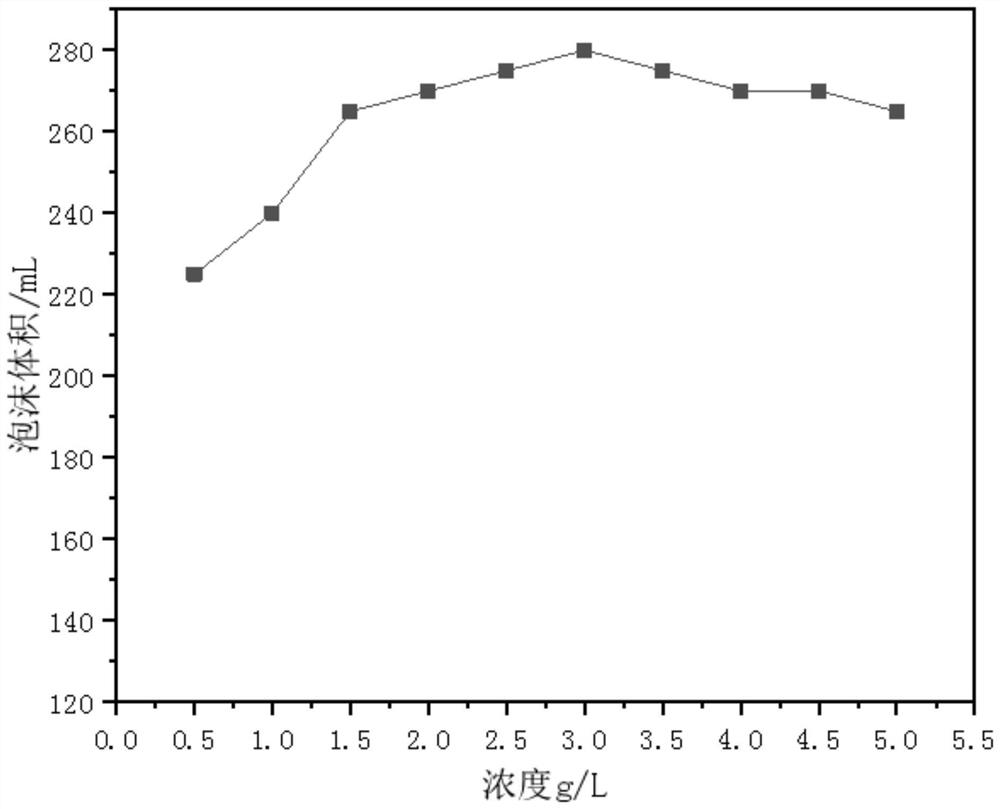

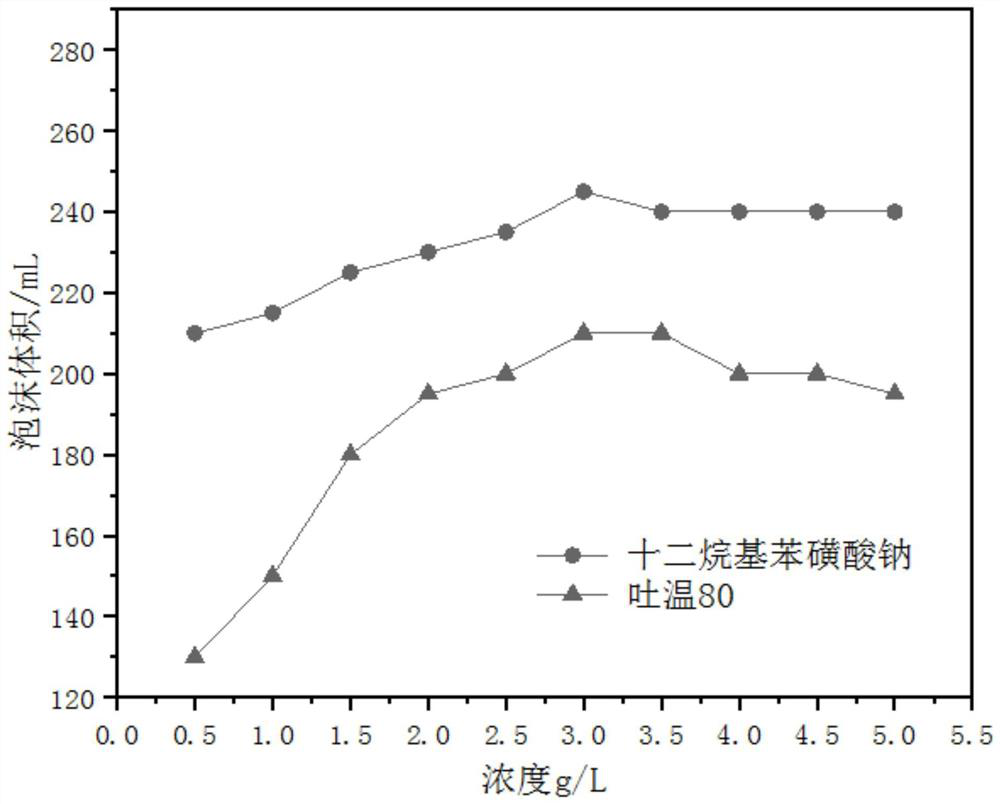

[0078] S3, add 0.4g hydrosulfite, 0.6g sodium hydroxide, foaming agent and stabilizer to 100mL indigo suspension under anaerobic environment, under 1200r / min, stir the foaming liquid for 3min to make it foam, and Foam is applied on pure cotton yarn, dyed, oxidized and fixed, and washed; wherein, the foaming agent concentration is 3g / L, and the foaming agent includes sodium lauryl sulfate, ten Sodium dialkylbenzenesulfonate and Tween 80, the stabilizer concentration is 1.2g / L, and the stabilizer includes citric acid, lauryl alcohol and...

Embodiment 2

[0081] The embodiment of the present application provides a kind of fabric indigo dyeing method, comprises the following steps:

[0082] S1. Add 0.3 g of indigo to 100 mL of water, then add 2.5 g of Tween 80 and 3.5 g of absolute ethanol, and ultrasonically disperse to obtain a dispersion;

[0083] S2. Filter the dispersion with a positive pressure filter, and then ultrasonically disperse it again after the filtration to obtain an indigo suspension;

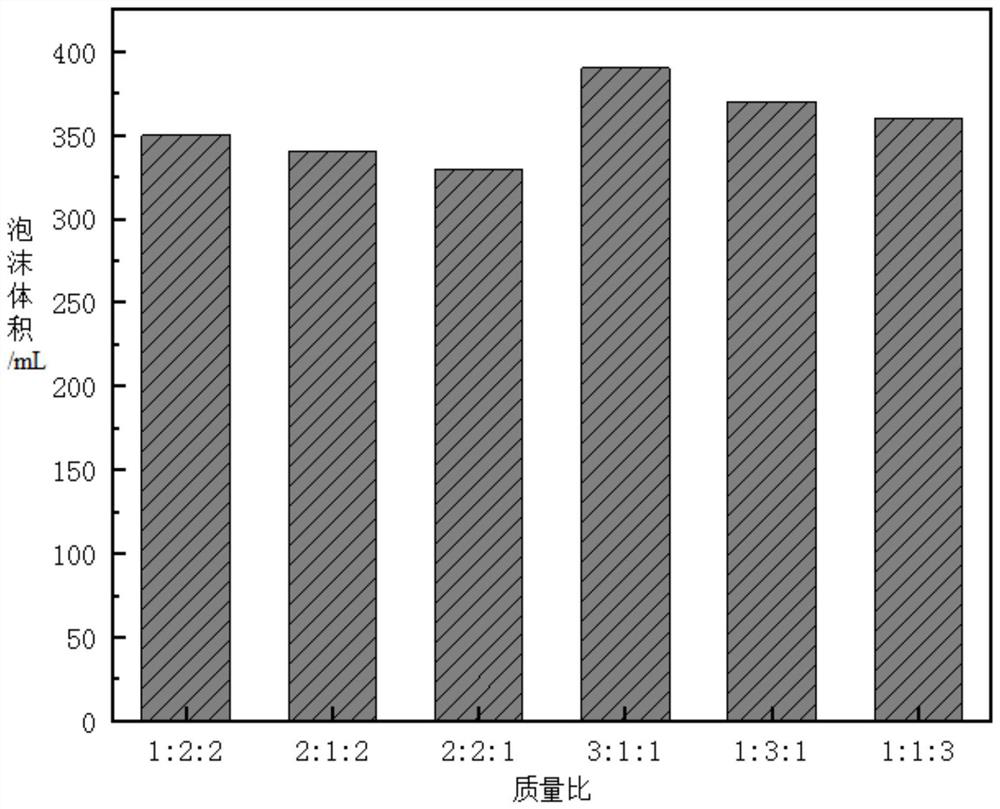

[0084] S3, add 0.4g hydrosulfite, 0.6g sodium hydroxide, foaming agent and stabilizer to 100mL indigo suspension under anaerobic environment, under 1200r / min, stir the foaming liquid for 3min to make it foam, and The foam is applied at a grammage of 206g / m 2 On pure cotton cloth, dyed, oxidized, and washed; wherein, the concentration of the foaming agent is 3g / L, and the foaming agent includes sodium lauryl sulfate and lauryl sulfate with a mass ratio of 3:1:1 Sodium benzenesulfonate and Tween 80, the stabilizer concentration i...

Embodiment 3

[0087] The embodiment of the present application provides a kind of fabric indigo dyeing method, comprises the following steps:

[0088] S1. Add 0.3 g of indigo to 100 mL of water, then add 2 g of Tween 80 and 3 g of absolute ethanol, and ultrasonically disperse to obtain a dispersion;

[0089] S2. Filter the dispersion with a positive pressure filter, and then ultrasonically disperse it again after the filtration to obtain an indigo suspension;

[0090] S3, add 0.4g hydrosulfite, 0.6g sodium hydroxide, foaming agent and stabilizer to 100mL indigo suspension under anaerobic environment, under 1200r / min, stir the foaming liquid for 3min to make it foam, and The foam is applied on pure cotton yarn, dyed, oxidized and fixed, and washed; wherein, the concentration of the foaming agent is 3g / L, the foaming agent is sodium lauryl sulfate, and the concentration of the stabilizer is 1.2g / L, which is stable The agent is citric acid;

[0091] Among them, the ultrasonic dispersion in S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com