Preparation method of alkali-free cold pad-batch dyed antibacterial skin-care fabric

A cold pad-batch dyeing and fabric technology, which is applied in the dyeing and finishing process of antibacterial skin care fabrics, can solve the problems of easy joint printing, large circular seam seam head, and large seam head extrusion, etc., and achieves stable weft shrinkage , Weft shrinkage rate is small, the effect of heat exchange is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Cationic modified cotton / cotton (70 / 30) blended wide-width woven fabric with a width of 106 inches and a yarn count of 40 s ×40 s , The density is 145×90 pieces / inch;

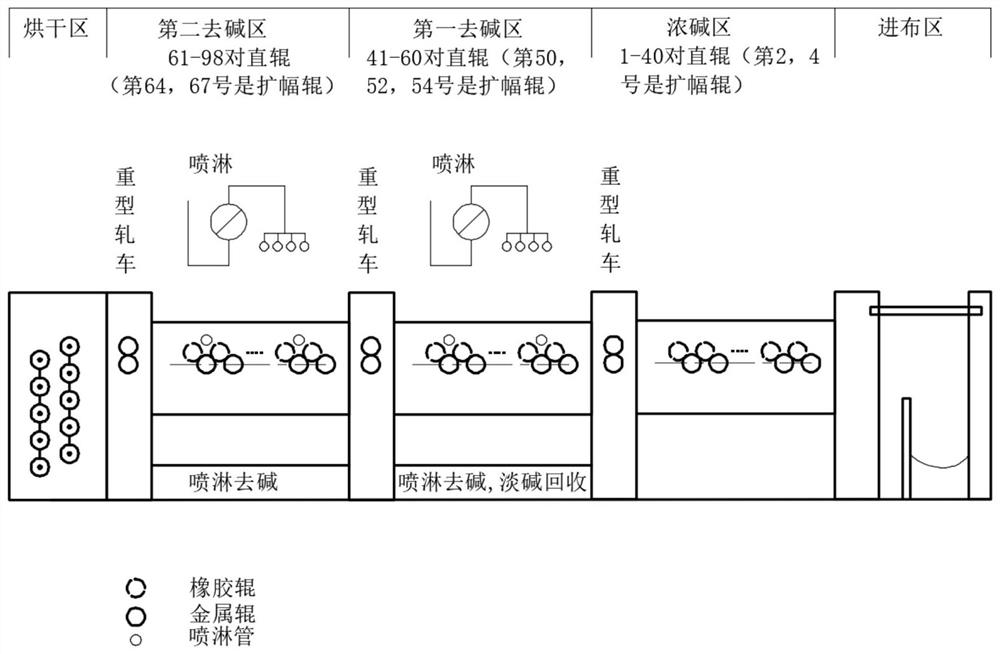

[0030] A preparation method of an alkali-free cold pad-batch dyed antibacterial skin care fabric, the main production process: seam turning → two positive and one reverse singeing → amylase stacking and desizing → scouring and bleaching machine → mercerizing with full straight roller mercerizing machine → Alkali-free cold pad-batch dyeing → formaldehyde-free anti-shrinkage and hyaluronic acid finishing agent in the same bath finishing → three-roll calender calendering → mechanical pre-shrinking → inspection and packaging; the specific operations are as follows:

[0031] In the described seam turning, a circular sewing machine is used, and the thread for the seam head is 30 s / 6, the stitch density is 28 stitches / 10cm, vertically sew 4cm on both sides of the selvedge, and trailing 3cm;

[0032] In the ...

Embodiment 2

[0045] Cationic modified cotton / cotton (70 / 30) blended wide-width woven fabric with a width of 118 inches and a yarn count of 50 s ×50 s , The density is 190×95 pieces / inch;

[0046] An alkali-free cold pad-batch dyed antibacterial skin care fabric, the product is flat and has no creases, the color difference between front and back is ≧4 grades, the color difference between left, middle and right is ≧4-5 grades, the soaping fastness is ≧4 grades, and the wet rubbing fastness is ≧3- Grade 4, pilling performance≧4 grade, breaking strength≧300N, washing dimensional change rate -3.0%~+0.5%.

[0047] The specifications of the quaternary ammonium cationic modified cotton / cotton (70 / 30) blended wide-width woven fabric are one of the following two types: the first type has a width of 106 inches and a yarn count of 40 s ×40 s , the density is 145×90 / inch; the second door width is 118 inches, and the yarn count is 50 s ×50 s , The density is 190×95 pieces / inch;

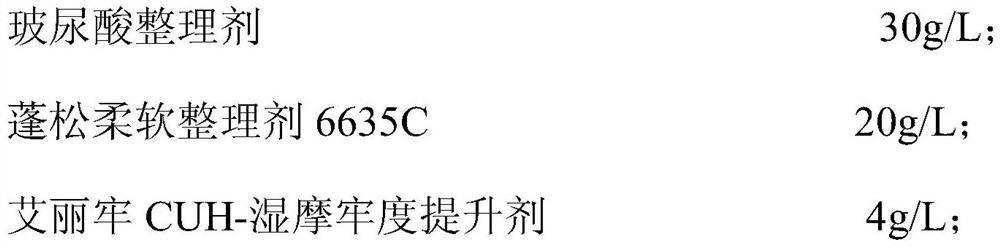

[0048] A preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fracture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com