A kind of polyester fabric treatment solution for printing and using method thereof

A polyester fabric and treatment liquid technology, applied in the field of printing and dyeing, can solve the problems of high water consumption, poor modification efficiency, unsatisfactory level dyeing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

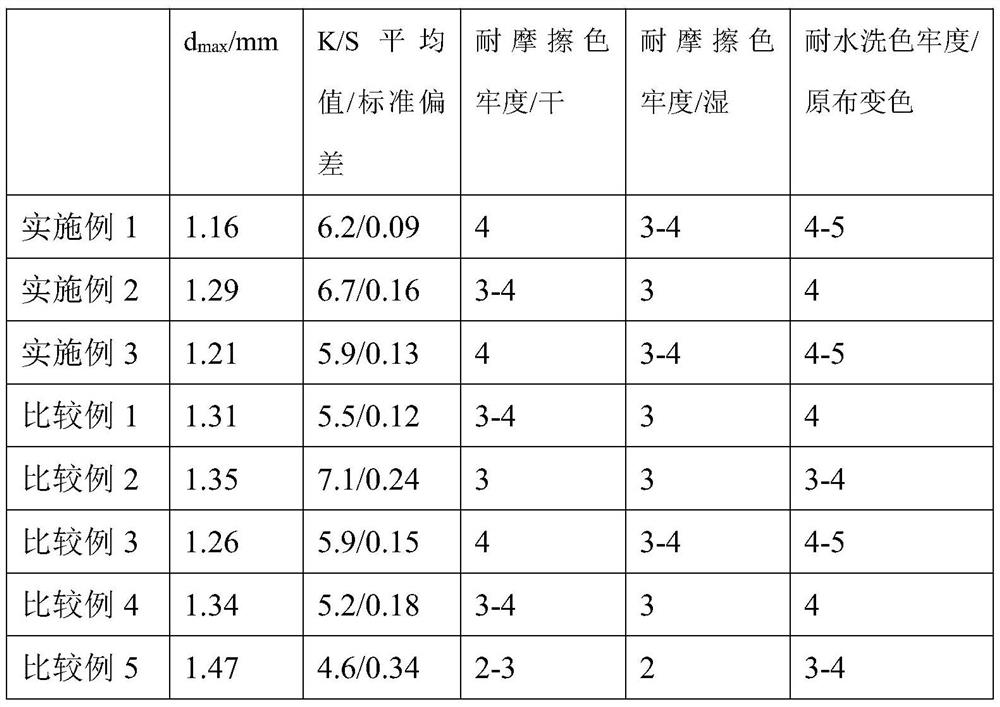

Examples

Embodiment 1

[0066] β-cyclodextrin and 2,3-epoxypropyltrimethylammonium chloride were incubated at 65°C for 5 hours in the presence of sodium hydroxide; among them, β-cyclodextrin and 2,3-epoxypropyltrimethyl Ammonium chloride and sodium hydroxide are respectively 10 parts by weight, 2.5 parts by weight and 1 part by weight. Then add hydrochloric acid until the pH is less than 8, cool down to 5°C, and precipitate out. Disperse the precipitate in water, heat it to 85°C to dissolve it, and then drop it into isopropanol to obtain a precipitate; the volume ratio of water and isopropanol is 1:10. The above dissolution-precipitation process was repeated three times, and vacuum-dried to obtain the quaternary ammonium salt modified cyclodextrin. The IR spectrum shows that the -OH stretching vibration absorption peak on β-cyclodextrin is changed from 3325cm -1 Blue shift about 70-80cm -1 .

[0067] Mix 4.5 parts by weight of quaternary ammonium salt modified cyclodextrin, 0.08 parts by weight o...

Embodiment 2

[0071] β-cyclodextrin and 2,3-epoxypropyltrimethylammonium chloride were incubated at 65°C for 5 hours in the presence of sodium hydroxide; among them, β-cyclodextrin and 2,3-epoxypropyltrimethyl Ammonium chloride and sodium hydroxide are respectively 10 parts by weight, 5 parts by weight and 1 part by weight. Then add hydrochloric acid until the pH is less than 8, cool down to 5°C, and precipitate out. Disperse the precipitate in water, heat it to 85°C to dissolve it, and then drop it into isopropanol to obtain a precipitate; the volume ratio of water and isopropanol is 1:12. The above dissolution-precipitation process was repeated three times, and vacuum-dried to obtain the quaternary ammonium salt modified cyclodextrin. The IR spectrum shows that the -OH stretching vibration absorption peak on β-cyclodextrin is changed from 3325cm -1 Blue shift about 70-80cm -1 .

[0072] Mix 3.2 parts by weight of quaternary ammonium salt modified cyclodextrin and the remaining water, ...

Embodiment 3

[0076] β-cyclodextrin and 2,3-epoxypropyltrimethylammonium chloride were incubated at 65°C for 5 hours in the presence of sodium hydroxide; among them, β-cyclodextrin and 2,3-epoxypropyltrimethyl Ammonium chloride and sodium hydroxide are respectively 10 parts by weight, 2.5 parts by weight and 1 part by weight. Then add hydrochloric acid until the pH is less than 8, cool down to 5°C, and precipitate out. Disperse the precipitate in water, heat it to 85°C to dissolve it, and then drop it into isopropanol to obtain a precipitate; the volume ratio of water and isopropanol is 1:12. The above dissolution-precipitation process was repeated three times, and vacuum-dried to obtain the quaternary ammonium salt modified cyclodextrin. The IR spectrum shows that the -OH stretching vibration absorption peak on β-cyclodextrin is changed from 3325cm -1 Blue shift about 70-80cm -1 .

[0077] Mix 2.5 parts by weight of quaternary ammonium salt-modified cyclodextrin, 0.15 parts by weight o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com