Softener composition with fabric quick-drying function and preparation method thereof

The technology of a softener and a composition is applied in the field of a softener composition with a fabric quick-drying function and its preparation field, which can solve the problems of low efficiency, unfavorable environmental protection, poor biodegradability, etc., achieves good stability, reduces the amount of liquid efficiency, and the effect of shortening the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment and

[0044] Specific embodiment and test experiment

[0045] The cloth sample used in the present invention is pure cotton fabric.

[0046] The stability of the softener composition is carried out in the following manner: put the softener composition in a thermostat at 45°C±2°C for 24 hours, take it out and return it to room temperature for observation; put the softener composition at -5°C±1°C Place it in a low-temperature tank for 24 hours, take it out and return to room temperature for observation.

[0047] The yield stress of the softener composition is measured with a rheometer at 25°C, and the conditions are: 50mm lamina, angle 1 degree, measuring distance 98μm, heat preservation for 2 minutes, and shear rate range 0.01-10001 / s. .

[0048] Evaluate the rapid drying effect of the softener composition and use the following method to measure:

[0049] 1. Use a hardness of 250ppm (Ca 2+ : Mg 2+ =3: 2) the hard water preparation 1000ml concentration is the national standard la...

Embodiment 1-6

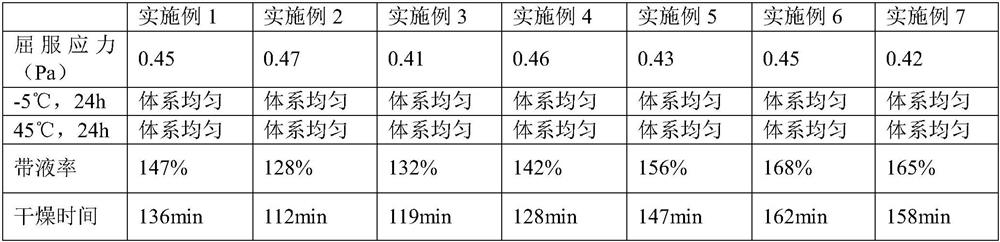

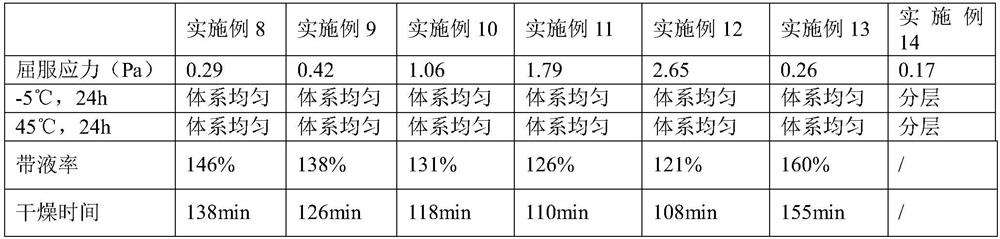

[0068] Weigh each component according to the formula in Table 1, and prepare the softener composition according to the following method: first mix and disperse the cationic surfactant and emulsifier in water, stir evenly; then add the rheology modifier to the above solution , and stir evenly; then add microcrystalline cellulose to the above solution, stir evenly, then add other additives and adjust the pH value to 4.0±0.5.

[0069] The composition of table 1 softener composition

[0070] Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Example 7 components content% content% content% content% content% content% content% VT-90 4.0 4.0 4.0 4.0 4.0 4.0 4.0 Tween-20 1.0 1.0 1.0 1.0 1.0 1.0 1.0 Dowsil 7700 0.5 0.5 0.5 0.5 0.5 0.5 0.5 MCC1 1.0 / / / / / / MCC2 / 1.0 / / / / / MCC3 / / 1.0 / / / / MCC4 / / / 1.0 / / / MCC5 / / / / 1.0 / / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com