Foam finishing agent and finishing method for sms nonwoven fabric

A technology for foam finishing and non-woven fabrics, applied in the field of foam finishing agent and finishing of SMS non-woven fabrics, can solve the problems of uneven spraying, poor wettability, and poor air permeability in surface spraying treatment, and achieve good application prospects, The effect of reducing elongation at break and air permeability and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: A foam finishing method for SMS nonwovens

[0028] The finishing steps and process conditions are as follows:

[0029] (1) Preparation of finishing solution: take Transoft 4917 softener 10 g / L, sodium carboxymethyl cellulose 15 g / L, sodium lauryl sulfate 15 g / L, foaming agent, softener and stabilizer dissolve in water;

[0030] (2) Stirring and foaming: Stir the solution obtained in step (1) at 25°C for 5 minutes;

[0031] (3) Finishing: apply the foaming finishing solution obtained in step (2) to the SMS nonwoven fabric by padding for soft and hydrophilic finishing, wherein the bath ratio is 1:30;

[0032] (4) Drying: Dry the SMS non-woven fabric after step (3) at 80°C for 3 minutes;

[0033] (5) Baking: The SMS nonwoven fabric dried in step (4) was baked at 130°C for 2 minutes to complete the foam finishing of the SMS nonwoven fabric.

Embodiment 2

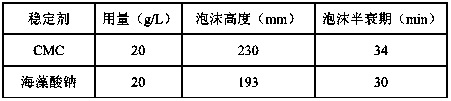

[0034] Embodiment two: foaming process verification of the present invention

[0035] 1. Determination of foaming temperature

[0036] Studies have shown that temperature has a great influence on foaming. When other conditions remain unchanged, the solution containing foaming agent and soft hydrophilic agent configured in the pre-experiment is mechanically foamed. The foaming temperature has a great influence on the foaming effect. The influence of the system performance is shown in Table 1:

[0037] Table 1 Effect of temperature on foam properties

[0038]

[0039] It can be seen from Table 1 that the foaming temperature reaches the highest value of 20-25°C, which has good foaming performance, and the viscosity of the solution decreases as the foaming temperature increases. When the temperature is too low, the foam activity is not strong, the thermal movement between molecules is weakened, and the foaming effect is not good. When the temperature is too high, the viscosit...

Embodiment 3

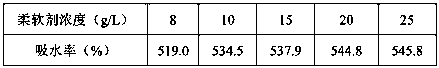

[0060] Example 3: Hydrophilic soft foam finishing single factor verification test

[0061] 1. Determination of softener concentration

[0062] Prepare the softener into finishing liquids with different concentrations, put the samples to be finished into it, pad and pad for finishing, two dips and two pads, the bath ratio is 1:40, the excess padding rate is 106%, and then pre-baked at a temperature of 80°C 3min, and then baked at 110°C for 2min. After finishing the fabric with different concentrations of finishing solution, the water absorption rate of the sample was measured, and the measurement results are shown in Table 6 below:

[0063] Table 6 Water absorption of samples after finishing with different softener concentrations

[0064]

[0065] It can be concluded from Table 6 that with the continuous increase of the concentration of Transoft 4917 functional softener, the water absorption of the samples after finishing first gradually increased and then showed a stable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com