A kind of high strength and toughness alcrsc alloy powder for 3d printing and its preparation method and application

A 3D printing, aluminum alloy technology, applied in the field of high-strength and tough AlCrSc alloy powder for 3D printing and its preparation, can solve the problems of poor oxidation resistance and stress corrosion resistance, unstable parts quality, printing failure, etc., and achieve good fatigue resistance. Performance, low resolution strength, low anisotropy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

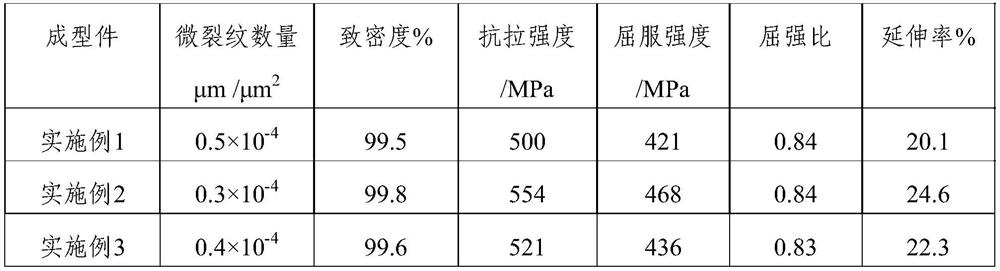

Examples

Embodiment 1

[0060] This embodiment provides a special aluminum alloy powder for SLM printing, which contains the following components by mass percentage: Cr: 1.5%, Sc: 0.5%, Zr: 0.3%, Si: 0.8%, Mn: 0.3%, Mg: 0%, Ti: 0.1%, Fe: 0.1%, Ni: 0.1%, Ce: 0.01%, Sr: 0.01%, Er: 0.01%, La: 0.01%, the balance is Al, the sum of the above components by mass percentage is 100%.

[0061] in:

[0062] The total content of Si+Mg is 1.8%;

[0063] The mass ratio of Sc / Zr is 1.67;

[0064] The total content of Mn+Fe is 0.4%.

[0065] The present embodiment also provides a method for preparing the above-mentioned special aluminum alloy powder for SLM printing. The steps are as follows:

[0066] The raw materials are extracted from the above components according to the set mass ratio, and the raw materials are extracted in the form of pure alloy or intermediate alloy. The obtained powder is subjected to vibratory sieving or air classification.

[0067] Conditions for vacuum induction melting: the degree o...

Embodiment 2

[0073] This embodiment provides a special aluminum alloy powder for SLM printing, which contains the following components by mass percentage: Cr: 3.0%, Sc: 0.8%, Zr: 0.6%, Si: 1.0%, Mn: 0.35%, Mg: 3.0%, Ti: 0.1%, Fe: 0.05%, Ni: 0.1%, Ce: 0.01%, Sr: 0.01%, Er: 0.01%, La: 0.01%, the balance is Al, the sum of the mass percentages of the above components is 100%.

[0074] in:

[0075] The total content of Si+Mg is 4.0%;

[0076] The mass ratio of Sc / Zr is 1.3;

[0077] The total content of Mn+Fe is 0.4%.

[0078] The present embodiment also provides a method for preparing the above-mentioned special aluminum alloy powder for SLM printing. The steps are as follows:

[0079] The raw materials are extracted from the above components according to the set mass ratio, and the raw materials are extracted in the form of pure alloy or intermediate alloy. The obtained powder is subjected to vibratory sieving or air classification.

[0080] Conditions for vacuum induction melting: the ...

Embodiment 3

[0086] This embodiment provides a special aluminum alloy powder for SLM printing, which contains the following components by mass percentage: Cr: 4.0%, Sc: 0.6%, Zr: 0.6%, Si: 1.0%, Mn: 0.3%, Mg: 3.5%, Ti: 0.1%, Fe: 0.01%, Ni: 0.1%, Ce: 0.01%, Er: 0.01%, La: 0.01%, the balance is Al, and the sum of the mass percentages of the above components is 100%.

[0087] in:

[0088] The total content of Si+Mg is 4.5%;

[0089] The mass ratio of Sc / Zr is 1;

[0090] The total content of Mn+Fe is 0.31%.

[0091] The present embodiment also provides a method for preparing the above-mentioned special aluminum alloy powder for SLM printing. The steps are as follows:

[0092] The raw materials are extracted from the above components according to the set mass ratio, and the raw materials are extracted in the form of pure alloy or intermediate alloy. The obtained powder is subjected to vibratory sieving or air classification.

[0093] Conditions for vacuum induction melting: the degree of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com