Reagent for breaking and removing boron cross-linking agent and preparation method thereof

A technology of cross-linking agent and medicament, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of long gel breaking time, narrow application range, low enzymatic activity, etc., and achieve high gel breaking efficiency and application range. The effect of wide and short glue breaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing a medicament for breaking the boron crosslinking agent, specifically comprising the following steps:

[0036] (1) Slowly add the peroxide into the deionized water, heat while stirring, the stirring rate is 100-120 rpm, the temperature is controlled at 30°C, stir at constant temperature for 1 hour and naturally cool to room temperature to obtain the peroxide solution;

[0037] (2) Slowly add the gel breaking activator into the above peroxide solution, heat while stirring, the stirring rate is 80-100 rpm, the temperature is controlled at 30°C, keep the temperature for 3-5 hours and then cool naturally to room temperature to obtain a mixed solution ;

[0038] (3) Add the sugar accelerator compound initiator into the above mixed solution, heat while stirring, the stirring rate is 200-300 rpm, the temperature is controlled at 40-45 °C, and the temperature is lowered to 30-30 °C after 2-4 hours. 40 ℃, constant temper...

Embodiment 1

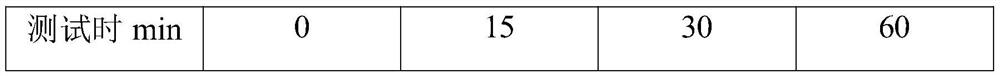

[0043] Measure 50mL of the treated fracturing flowback fluid, adjust the temperature to 50°C, and the stirring speed at 250r / min, add 0.2mL of the medicament for breaking the boron crosslinking agent of the present invention to it, respectively at 0min, 15min, The viscosity of the fracturing flowback fluid was tested at 30 minutes and 60 minutes, and the gel breaking performance of the agent used to break the boron crosslinking agent was investigated.

[0044]

[0045]

Embodiment 2

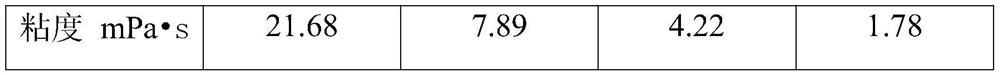

[0047]Measure 50mL of the treated fracturing flowback fluid, adjust the temperature to 40°C, and the stirring speed at 500r / min, add 0.3mL of the medicament for breaking the boron crosslinking agent of the present invention to it, respectively at 0min, 15min, The viscosity of the fracturing flowback fluid was tested at 30 minutes and 60 minutes, and the gel breaking performance of the agent used to break the boron crosslinking agent was investigated.

[0048] min during test 0 15 30 60 Viscosity mPa·s 22.18 6.54 4.18 1.66

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com