Tailor welding method for hydraulic support push rod with liquid supply and return function

A hydraulic support and push rod technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of reduced reliability of the liquid supply structure, failure to meet the quality requirements of the push rod, thermal deformation of the inner hole of the joint seat, etc., to achieve Guaranteed cleanliness, good liquid tightness, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

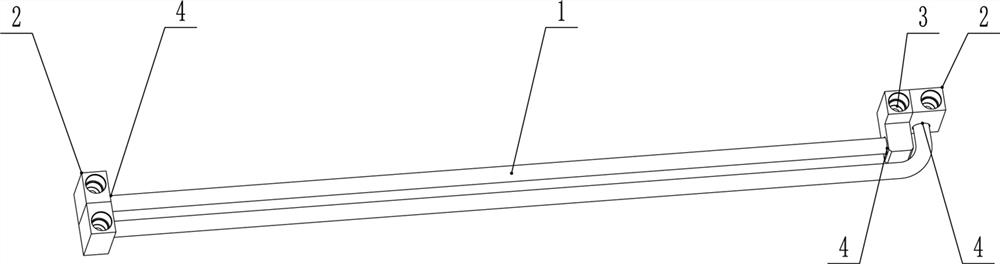

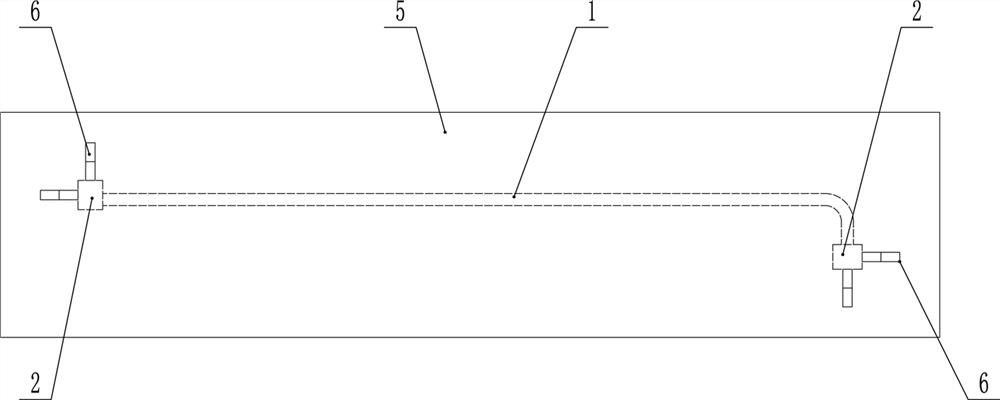

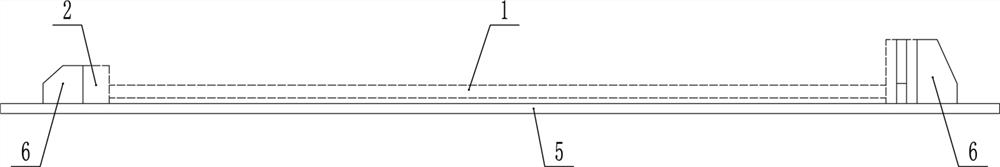

[0039] like Figure 1-9 As shown, the push rod targeted by the present invention includes a cover plate 13, a middle plate 11, a bottom plate 15, and a liquid supply and return mechanism. For the connector seats 2 at both ends, the middle plate 11 is provided with a hollow mounting groove corresponding to the liquid supply and return mechanism, and the cover plate 13 is provided with installation through holes corresponding to the connector seat 2 .

[0040] The present invention uses a special assembly platform when assembling the liquid pipe 1 and the joint seat 2. The special assembly platform includes an assembly base plate 5 and a joint seat positioning block 6 arranged on the assembly base plate 5. The flatness of the assembled bottom plate 5 is not greater than 1 / 1000, and the error of position and dimension accuracy of the joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com