Production method of Wuchang rice rich in gamma-aminobutyric acid

A production method, the technology of aminobutyric acid, applied in the field of grain processing, can solve the problems of potential safety hazards, long time, and long use, and achieve the effect of relieving anxiety, reducing waist burst, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

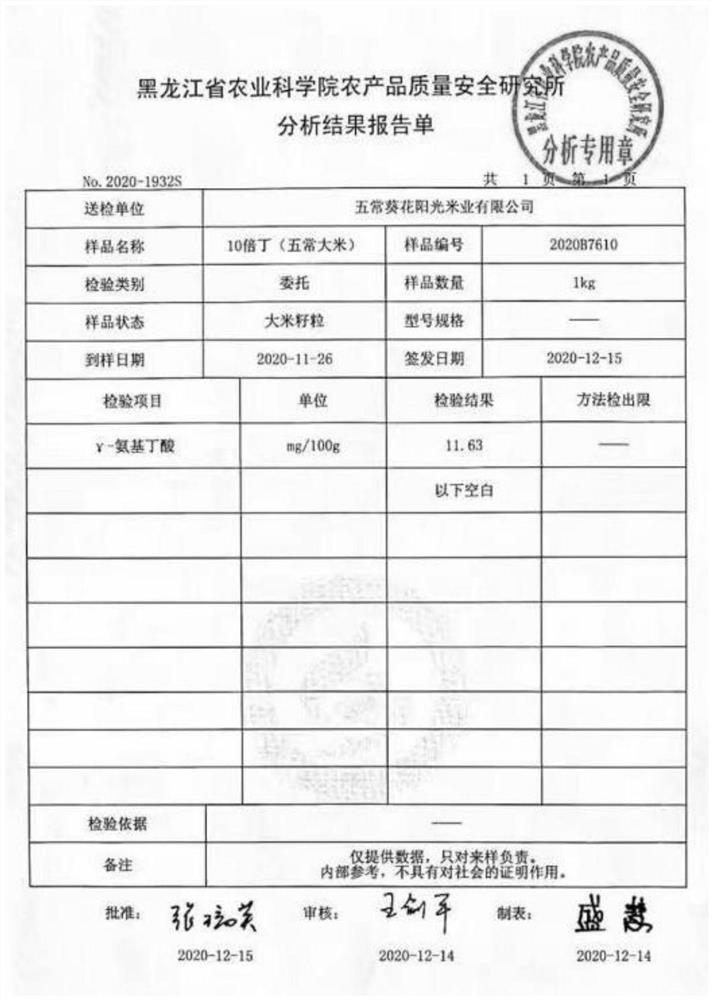

Examples

Embodiment 1

[0044] Embodiment 1 is rich in the production method of the Wuchang rice of gamma-aminobutyric acid

[0045] 1. Production method

[0046] 1) Raw material screening: rice is used as raw material, the rice is new local grain in Wuchang, impurity is removed (impurity is less than 0.8), the germination rate is not less than 93%, the moisture content is 14.5-15%, and the test roughness rate is 78% Above, the polished rice rate is over 64%, reaching the national standard GB / T 19266;

[0047]2) Humidification: put the rice in the tank, and then humidify through 6 humidification sections in sequence, so that the relative humidity of the raw material reaches 94%, the temperature reaches 40°C, and the moisture content increases to 20%;

[0048] Among them, the six humidification sections include:

[0049] Humidification 1 section: air supply temperature 60°C, supply air humidity 94%, humidification for half an hour, moisture value reaches 15.3%, the system automatically enters humidi...

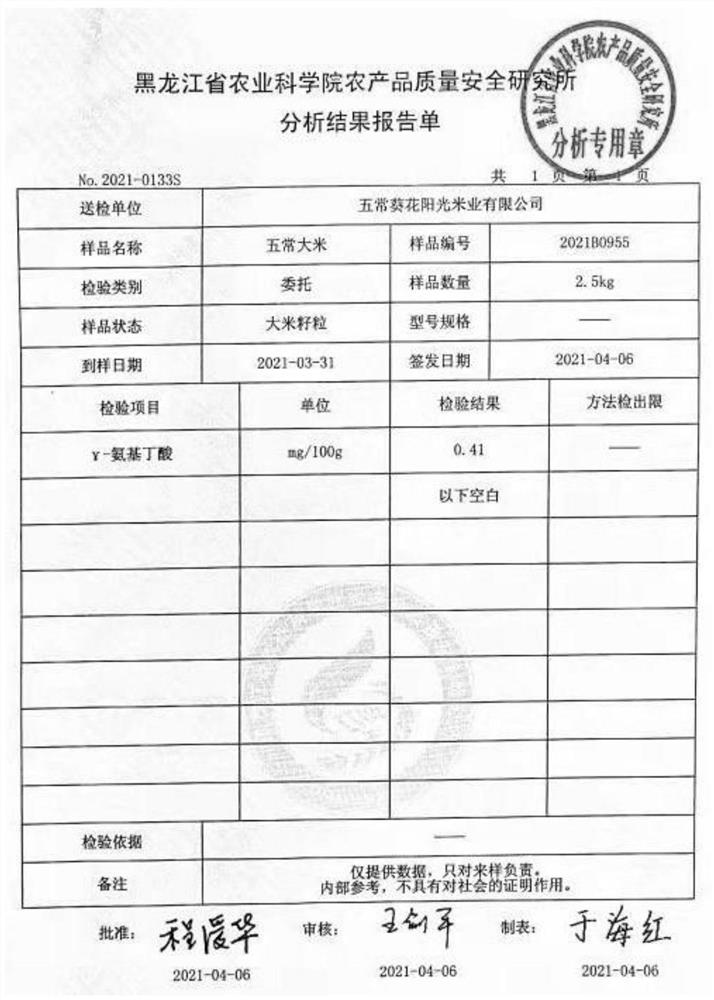

Embodiment 2

[0068] Embodiment 2 is rich in the production method of the Wuchang rice of gamma-aminobutyric acid

[0069] 1. Production method

[0070] 1) Raw material screening: rice is used as raw material, the rice is new local grain in Wuchang, impurity is removed (impurity is less than 0.8), the germination rate is not less than 93%, the moisture content is 14.5-15%, and the test roughness rate is 78% Above, the polished rice rate is over 64%, reaching the national standard GB / T 19266;

[0071] 2) Humidification: put the rice in the tank, and then humidify through 6 humidification sections in sequence, so that the relative humidity of the raw material reaches 90%, the temperature reaches 45°C, and the moisture content increases to 19%;

[0072] Among them, the six humidification sections include:

[0073] Humidification 1 section: air supply temperature 60°C, supply air humidity 94%, humidification for half an hour, moisture value reaches 15.5%, the system automatically enters humid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com