Energy-saving induction heating device

An induction heating device and the technology of the induction device are applied in the directions of induction heating, coil devices, furnaces without annular cores, etc., which can solve the problems of increasing project cost, reducing power utilization rate, and consuming water resources of water cooling system, so as to improve the efficiency of water cooling system. Antioxidant effect, reduce project cost and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0061] Take the first tubular heating device, and further explain from the energy-saving principle and energy-saving effect,

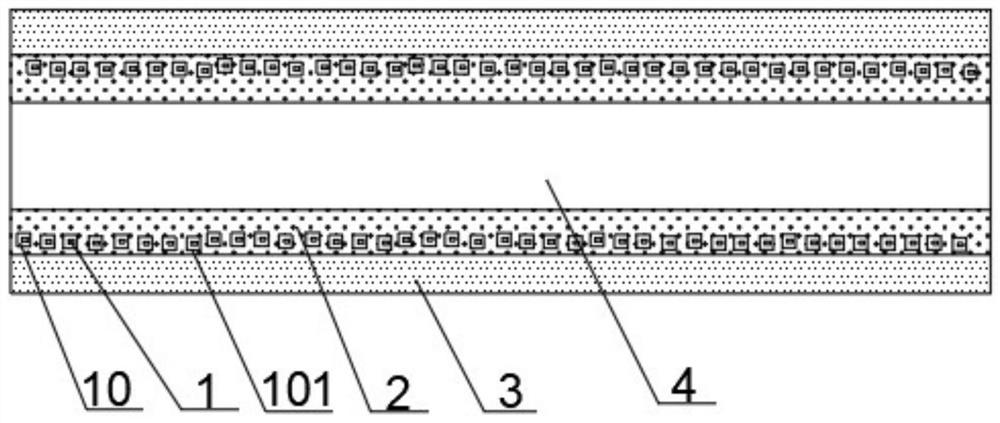

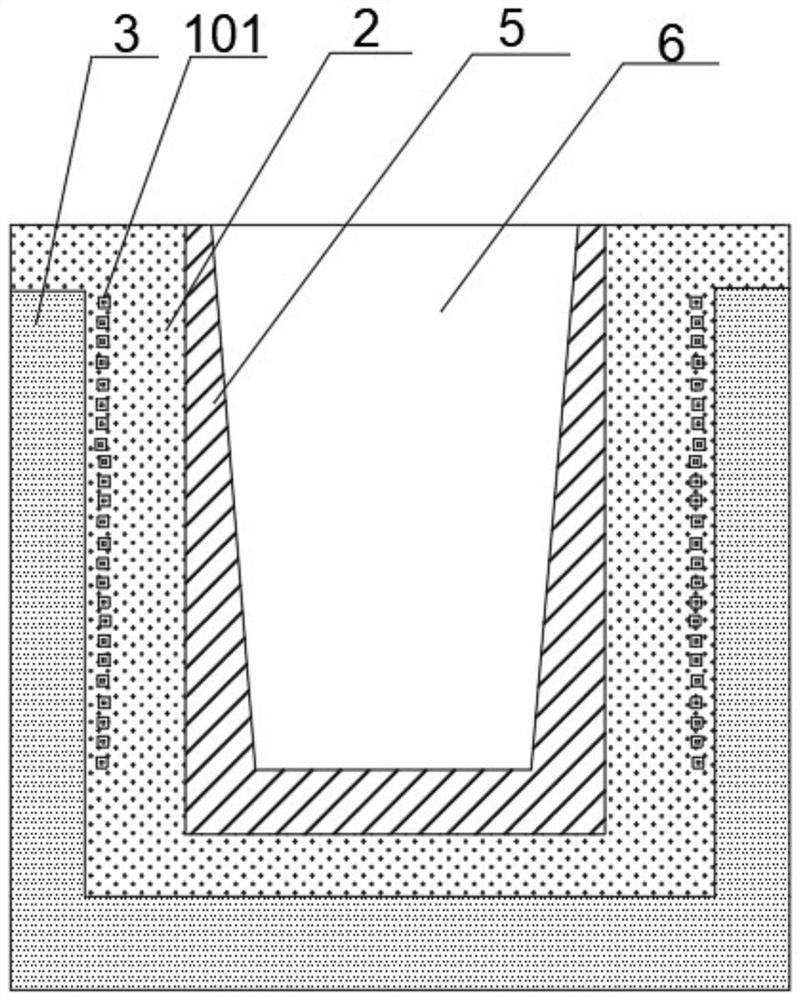

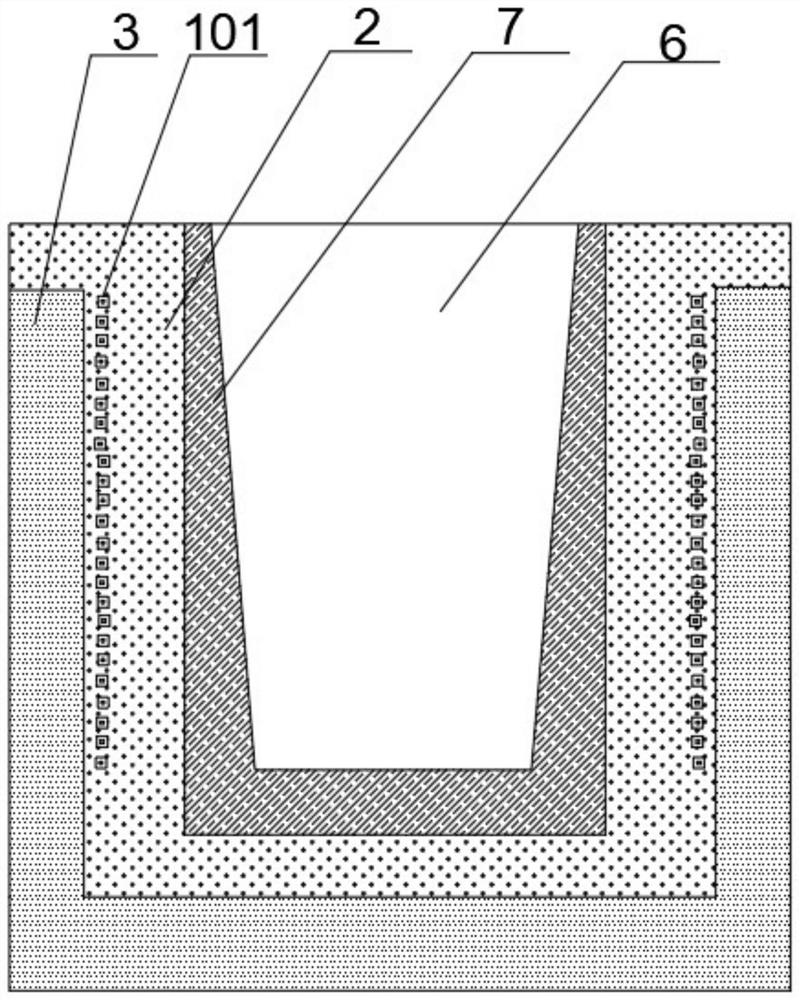

[0062] Let the inner radius of the refractory material pipe, that is, the refractory layer inclusion 2, be r 0 , the outer radius is r 1 , the thermal conductivity of the refractory material is λ 0 (1+α 0 t), the inner wall temperature is T 0 , where, if the heated metal is a solid metal, the temperature is slightly lower than the metal temperature, and if it is a liquid metal, it is equal to the liquid metal temperature; r 1 The temperature at the location is T 1 , the inner radius of the insulation layer 3 is r 1 (ignoring the sensor thickness), the outer radius is r 2 , the thermal conductivity of the insulating material is λ 1 (1+α 1 t), the surface temperature of the insulation layer 3 is T 2 , the ambient temperature is T 环 , the heat transfer coefficient between the insulation material and the environment is β.

[0063] According to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com