High-precision hand-eye calibration method for garbage sorting robot

A hand-eye calibration and robot technology, which is applied in the fields of instruments, sorting, image analysis, etc., can solve the problems of low calibration accuracy and poor material grasping, and achieve the requirements of low accuracy, reduce calibration difficulty and cost, and reduce calibration errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

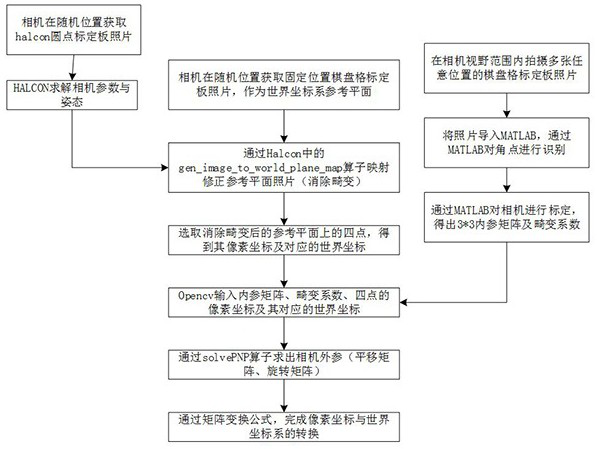

[0060] A high-precision hand-eye calibration method for a garbage sorting robot of the present invention, such as figure 1 As shown, the eye-to-hand system for parallel robots is suitable, and the system is composed of three parts: vision module, robot module, and transmission module; among them, the length of the conveyor belt used by the transmission module is 4m, the width is 0.9mm, and the maximum speed can reach 2m / s; the vision module adopts a 5 million pixel CMOS industrial camera, and its lens focal length is 8mm, the vision module is located at the front end of the robot module, and is fixed at a height of 1m above the conveyor belt; The working range is 900mm and it is fixed above the conveyor belt.

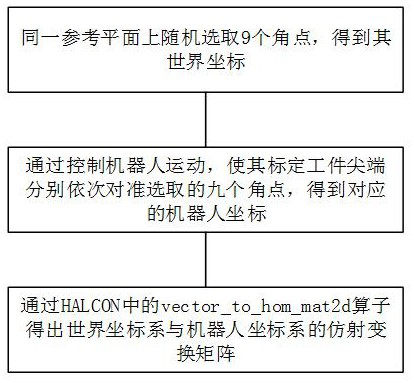

[0061] A high-precision hand-eye calibration method for a garbage sorting robot of the present invention, such as Figure 1~4 shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com