Vehicle-mounted straw incineration and grain drying device

A drying device and incineration device technology, applied in drying, drying machine, drying gas arrangement, etc., can solve problems such as loading and unloading, transportation, and storage difficulties, and achieve the effects of multiple functions, resource saving, and air pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment:

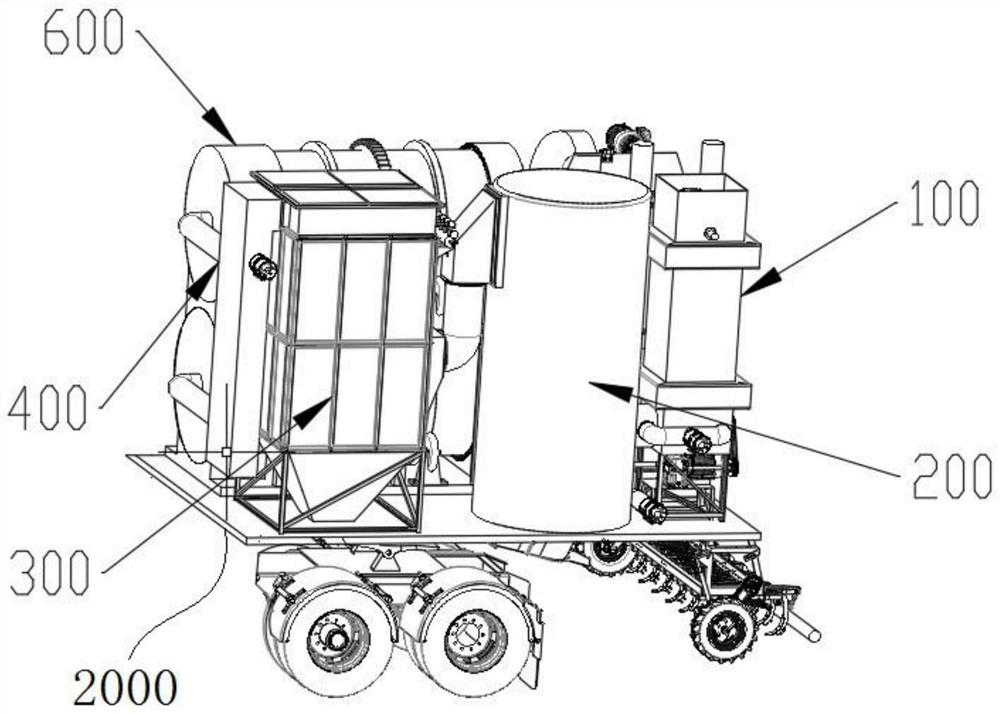

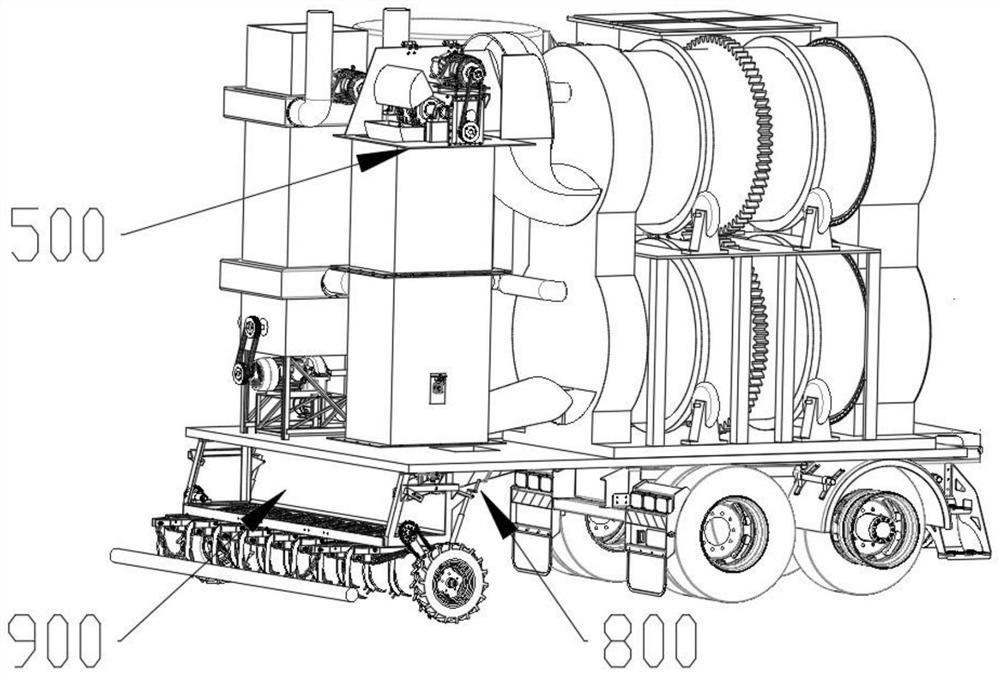

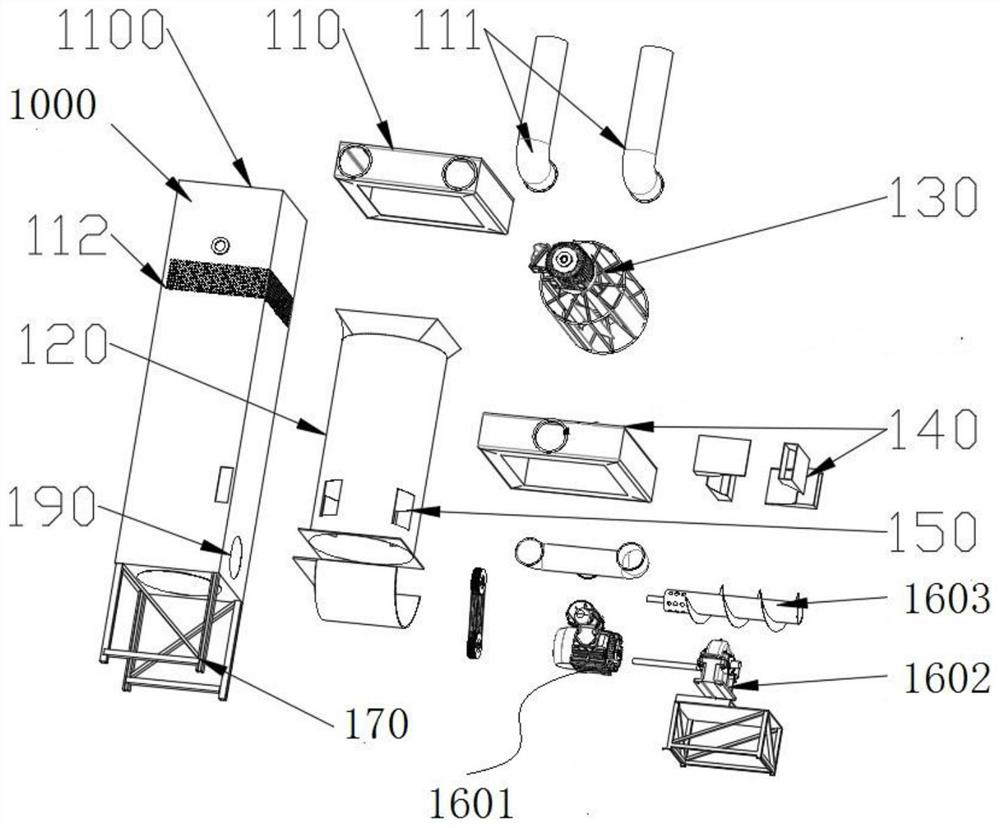

[0049] Such as Figure 1-Figure 2 As shown, a vehicle-mounted straw incineration and grain drying device of the present invention includes a chassis and a straw cutting and drying device 100 arranged on the chassis 2000, a straw incineration device 200, a bag dust removal device 300, a bucket lifting device 500, and a drum Drying device 600 , temporary ash storage device 700 , plant ash stirring device 800 and deep-buried back-to-field device 900 .

[0050] The straw cutting and drying device 100 communicates with the straw incineration device 200 , and discharges the straw into the straw incineration device 200 after cutting and drying. The straw incineration device 200 communicates with the bag dust removal device 300 , and the plant ash stirring device 800 is arranged at the bottom of the straw incineration device 200 . The straw incineration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com