Process for producing high-purity praseodymium neodymium oxide by using neodymium iron boron smelting slag

A technology of praseodymium neodymium oxide and neodymium iron boron, which is applied to the preparation/processing of rare earth metal oxides/hydroxides, lanthanide oxides/hydroxides, and rare earth metal compounds, and can solve the problems of high production costs, Problems such as low purity of praseodymium and neodymium oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a process for producing high-purity praseodymium-neodymium oxides with NdFeB smelting slag. In terms of formula percentage, the process for producing high-purity praseodymium-Nd oxides with NdFeB smelting slag includes NdFeB smelting slag 80 -90 parts, 35-40 parts of hydrochloric acid, 80-90 parts of praseodymium and neodymium chloride solution, 55-60 parts of ammonium bicarbonate solution and 40-50 parts of distilled water;

[0026] Preferably, in terms of formula percentage, the process of producing high-purity NdFeB slag from NdFeB smelting slag includes 86 parts of NdFeB smelting slag, 37 parts of hydrochloric acid, 82 parts of praseodymium and neodymium chloride solution, and 57 parts of ammonium bicarbonate solution and 43 parts of distilled water.

Embodiment 2

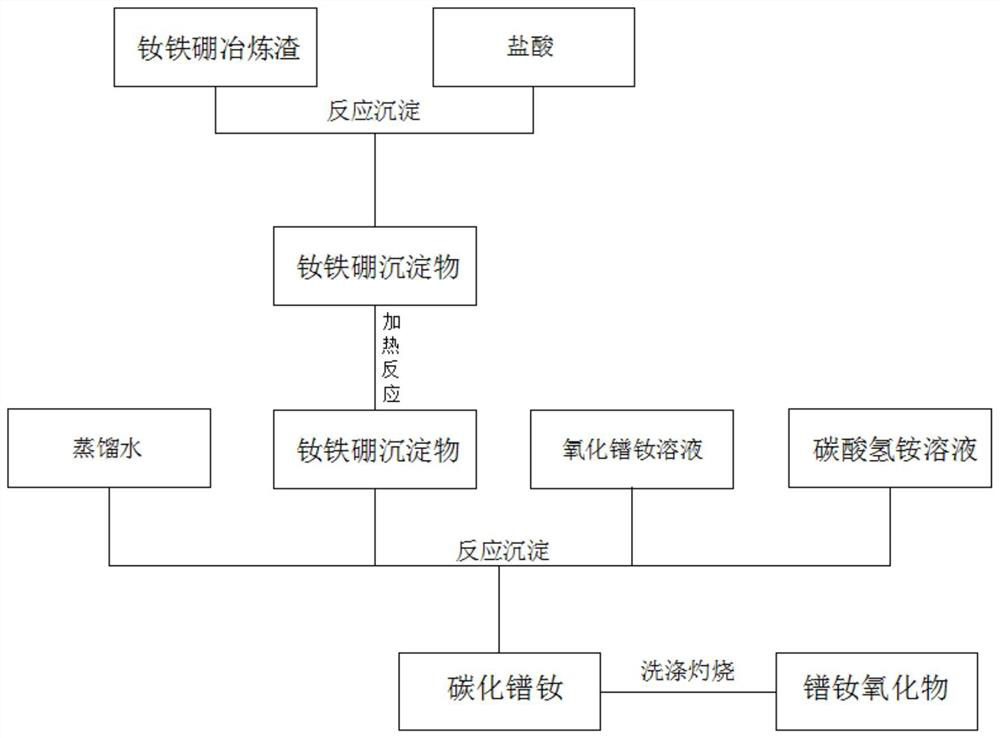

[0028] This embodiment provides a process for producing high-purity NdPr oxides with NdFeB smelting slag, and the specific steps are as follows:

[0029] (1) Reaction treatment: place the NdFeB smelting slag inside the reaction kettle, add hydrochloric acid at the same time, stir for 20-30min, then precipitate for 4-5 hours, and obtain NdFeB precipitate after precipitation;

[0030] (2) Heating reaction: the NdFeB precipitate obtained in step (1) is heated and reacted through a reactor, the internal temperature of the reactor is 90-100°C, and the reaction time is 30-40min;

[0031] (3) Rinse and filter: wash the NdFeB precipitate with hot water for 1-3 times, and filter it through a filter screen after washing. The mesh number of the filter screen is 150-200 mesh, and the number of filters is 2-4 times;

[0032] (4) Reaction precipitation: Fill distilled water into the reactor, then add praseodymium neodymium chloride solution and ammonium bicarbonate solution in sequence, kee...

Embodiment 3

[0040] First place the NdFeB smelting slag inside the reactor, add hydrochloric acid at the same time, stir for 20 minutes, and then precipitate for 4 hours. After precipitation, the NdFeB precipitate is obtained. The temperature is 90°C, the reaction time is 30 minutes, the NdFeB precipitate is washed once with hot water, and then filtered through a filter screen with a mesh number of 150 mesh, and the number of filters is 2 times, and distilled water is filled into the reactor , followed by adding praseodymium neodymium chloride solution and ammonium bicarbonate solution, keeping the flow rate of praseodymium neodymium chloride solution at 0.4mL / min, after maintaining for 30min, adding the filtered NdFeB precipitate, precipitating for 40min, and the precipitate obtained by precipitating Washing with hot water, the number of times of washing is 2 times, the precipitate obtained after washing is burned, the burning temperature is 1000°C, and the praseodymium neodymium oxide is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com