Automatic production line of solar cell panel packaging films

A technology of solar cells and automatic production lines, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the requirements of high-quality, high-efficiency and continuous production of thin-film products, cannot perform automatic control and automatic operation, and is difficult to guarantee the roll material. And film product quality and other issues, to avoid poor dispersion and mixing effect, to avoid uneven material composition, to ensure bonding strength and anti-aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

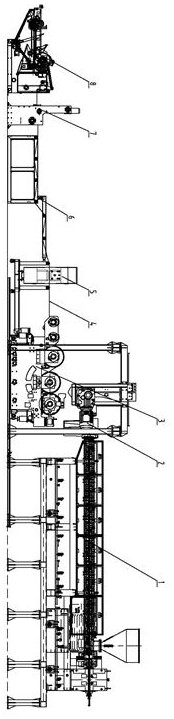

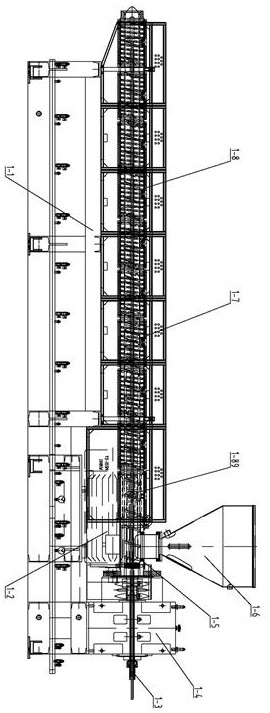

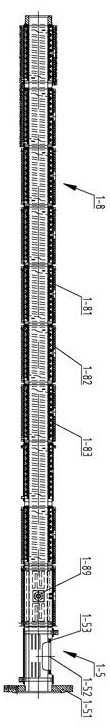

[0061] Such as figure 1 As shown, screw extruder 1, film casting machine 3, thickness gauge 5, haul-off machine 7 and film winder 8 are arranged sequentially on the path of melt extruding into film, and the screw of screw extruder 1 The discharge port of cylinder 1-83 is fixedly connected with the feed port of extrusion die 3-12 through the melt connector 2. The melt connector 2 mainly has a melt delivery pipeline, and a replacement Net device and metering pump, these structures and devices are common products in the market; the thickness gauge 5 adopts general products that can be used for online thickness measurement of films, such as the thickness gauge produced by Zhejiang Shuangyuan Technology Development Co., Ltd.; traction The machine 7 mainly includes a frosted steel roller that provides traction power for the film to form a traction to the film; the cooling bracket 6 includes a roller bracket, and a number of rotating rollers are rotatably supported on the roller brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com