Punching equipment used for capacitor shell machining

A technology for capacitors and shells, applied in the field of capacitor shell processing, can solve problems such as low energy utilization, workpiece damage, and difficulty in demoulding, and achieve the effects of rapid demoulding work, improved efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

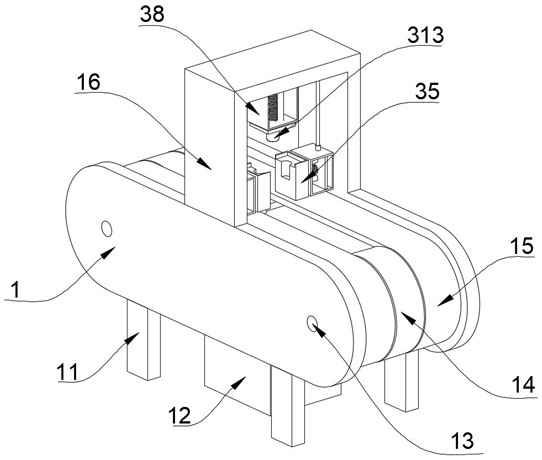

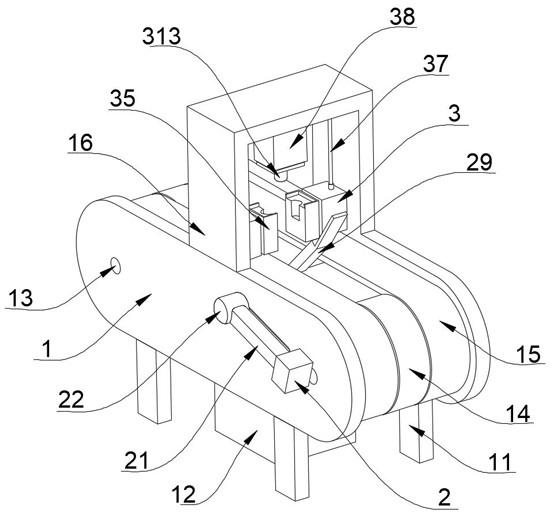

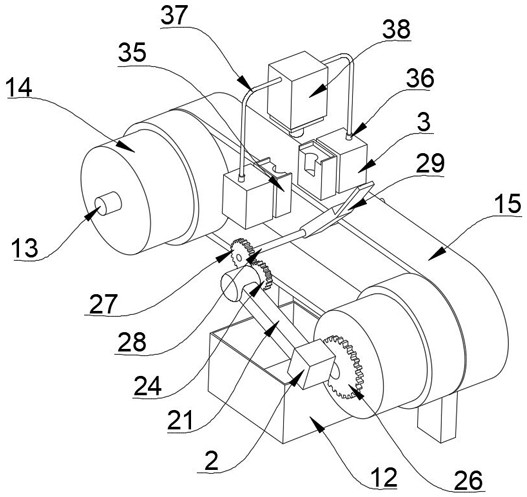

[0021] refer to Figure 1-5 , a punching equipment for capacitor shell processing, including: a transmission device, a transmission device and a stamping device, the transmission device is used to transport stamping raw materials, and the transmission device includes: a fixed block 1, a support column 11, a collection box 12. Transmission shaft 13, transmission roller 14, transmission belt 15, bracket 16, wherein the support column 11 is fixedly connected under the fixed block 1, the transmission shaft 13 is rotatably connected to the two fixed blocks 1, and the transmission roller 14 is coaxially fixedly connected to the On the conveying shaft 13 , the conveying belt 15 is arranged on the conveying roller 14 , the collection box 12 is arranged under the conveying belt 15 , and the bracket 16 is fixedly connected to the fixed block 1 .

[0022] The tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com