A Simple Preparation Method of Blue/Black Titanium Dioxide Photocatalyst Material

A technology of black titanium dioxide and photocatalytic materials, applied in the field of photocatalytic materials, can solve the problems of hindering the large-scale use of materials, low efficiency of photo-splitting water for hydrogen production, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

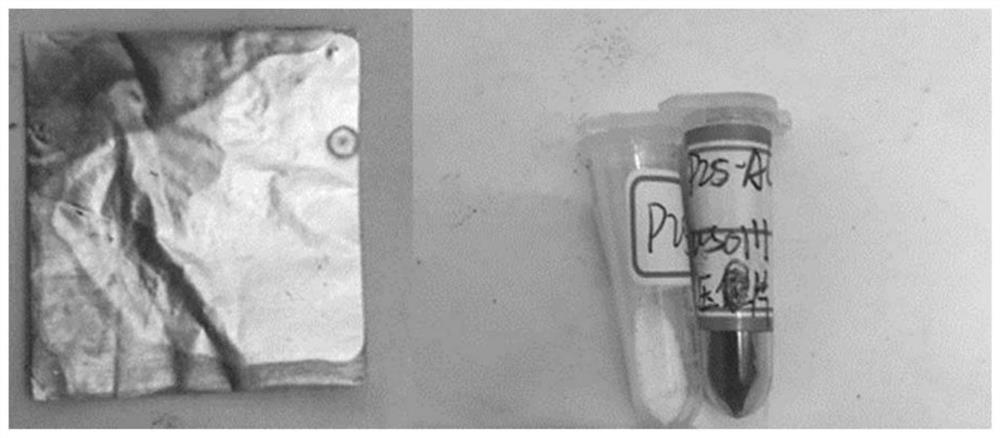

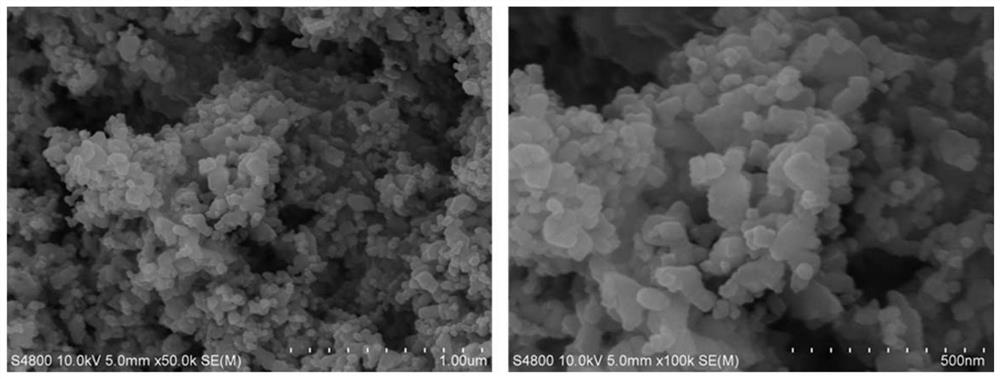

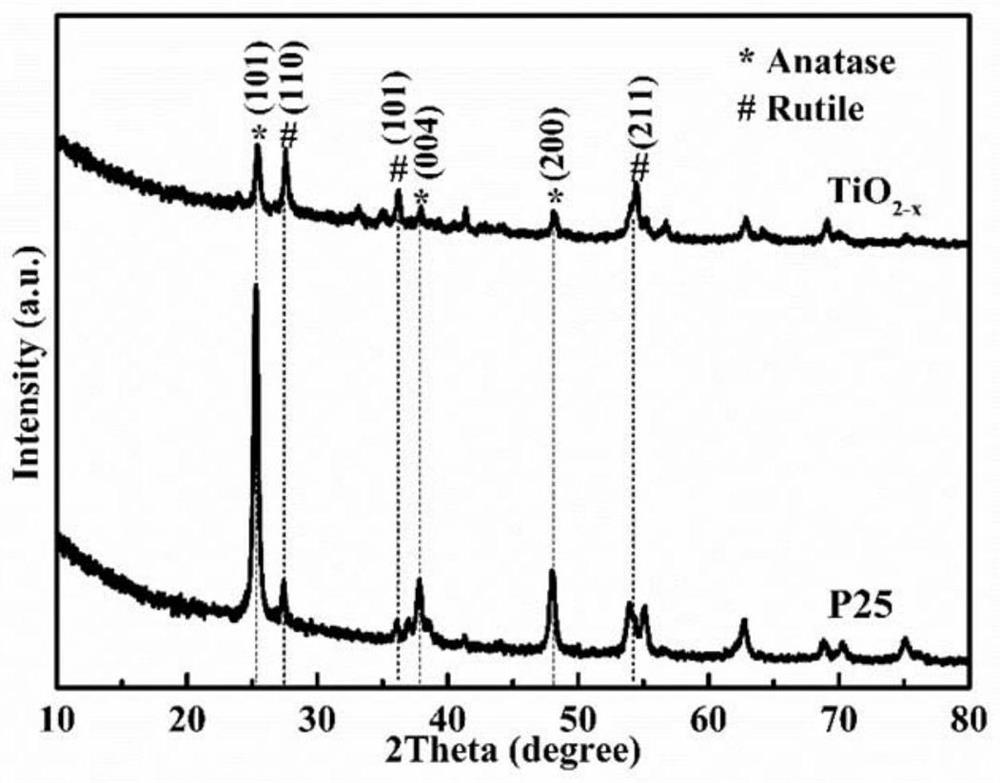

Embodiment 1

[0026] Cut the commercial aluminum foil paper to a size of 10cm×10cm, and fold it in half, fold the edges, etc. to get an aluminum foil bag of about 5cm×8cm. Then put 0.5 g of commercial titanium dioxide nanocrystalline particles (P25) weighed into an aluminum foil bag to close the mouth of the bag, and fold it into a 4cm×4cm aluminum foil sheet. Use a tablet machine to press the aluminum foil sheet wrapped with P25, so that the P25 is evenly distributed in the aluminum foil sheet and in close contact with the upper and lower layers of the aluminum foil sheet. Then use a corundum crucible to support the aluminum foil, place it in a tube furnace, feed 60 standard ml / min (60 sccm) of high-purity argon, and use a pressure reducing valve to control the argon pressure to 0.15 MPa. Before starting to heat up, pass argon for 60 minutes to remove the air in the quartz tube, then raise the temperature in the tube furnace to 600°C at a heating rate of 3°C / min, keep it at this temperatur...

Embodiment 2

[0029]Cut the commercial aluminum foil paper to a size of 10cm×10cm, and fold it in half, fold the edges, etc. to get an aluminum foil bag of about 5cm×8cm. Then put 0.5 g of commercial titanium dioxide nanocrystalline particles (P25) weighed into an aluminum foil bag to close the mouth of the bag, and fold it into a 4cm×4cm aluminum foil sheet. Use a tablet machine to press the aluminum foil sheet wrapped with P25, so that the P25 is evenly distributed in the aluminum foil sheet and in close contact with the upper and lower layers of the aluminum foil sheet. Then use a corundum crucible to support the aluminum foil, place it in a tube furnace, feed 60 standard ml / min (60 sccm) of high-purity argon, and use a pressure reducing valve to control the argon pressure to 0.15 MPa. Before starting to heat up, pass argon gas for 60mins to remove the air in the quartz tube, then raise the temperature in the tube furnace to 620°C at a heating rate of 3°C / min, keep at this temperature fo...

Embodiment 3

[0032] Cut the commercial aluminum foil paper to a size of 10cm×10cm, and fold it in half, fold the edges, etc. to get an aluminum foil bag of about 5cm×8cm. Then put 0.5 g of commercial titanium dioxide nanocrystalline particles (P25) weighed into an aluminum foil bag to close the mouth of the bag, and fold it into a 4cm×4cm aluminum foil sheet. Use a tablet machine to press the aluminum foil sheet wrapped with P25, so that the P25 is evenly distributed in the aluminum foil sheet and in close contact with the upper and lower layers of the aluminum foil sheet. Then use a corundum crucible to support the aluminum foil, place it in a tube furnace, feed 90 standard ml / min (90 sccm) of high-purity argon, and use a pressure reducing valve to control the argon pressure to 0.2 MPa. Before starting to heat up, pass argon gas for 40mins to remove the air in the quartz tube, then raise the temperature in the tube furnace to 600°C at a heating rate of 3°C / min, keep at this temperature fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com