A kind of silica-filled nano-cluster composite material and its preparation method and application

A nano-cluster and composite material technology is applied in the field of silica-filled nano-cluster composite materials and the preparation thereof, and achieves the effects of good photocatalytic water splitting for hydrogen production, controllable composition and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a silica-filled nanocluster composite material, comprising the following steps:

[0038] At room temperature, 1ml cyclohexane dispersed with tetraethyl orthosilicate (TEOS), Au nanocrystals and CdSe nanocrystals was mixed with 10ml sodium dodecyl sulfate (SDS) aqueous solution to form a microemulsion under ultrasonic conditions, and the ultrasonic power was 20%, ultrasonic 5min. Among them, the particle size of Au nanocrystals is 9nm, the concentration in cyclohexane dispersion is 1mg / ml, the particle size of CdSe nanocrystals is 3nm, and the concentration in cyclohexane dispersion is 5mg / ml, TEOS is added The amount is 100ul, and the concentration of sodium lauryl sulfate is 3mg / ml.

[0039] The microemulsion was heated at 343K for 4h, centrifuged and dried to obtain silica-filled Au / CdSe@SiO 2 nanocluster composites.

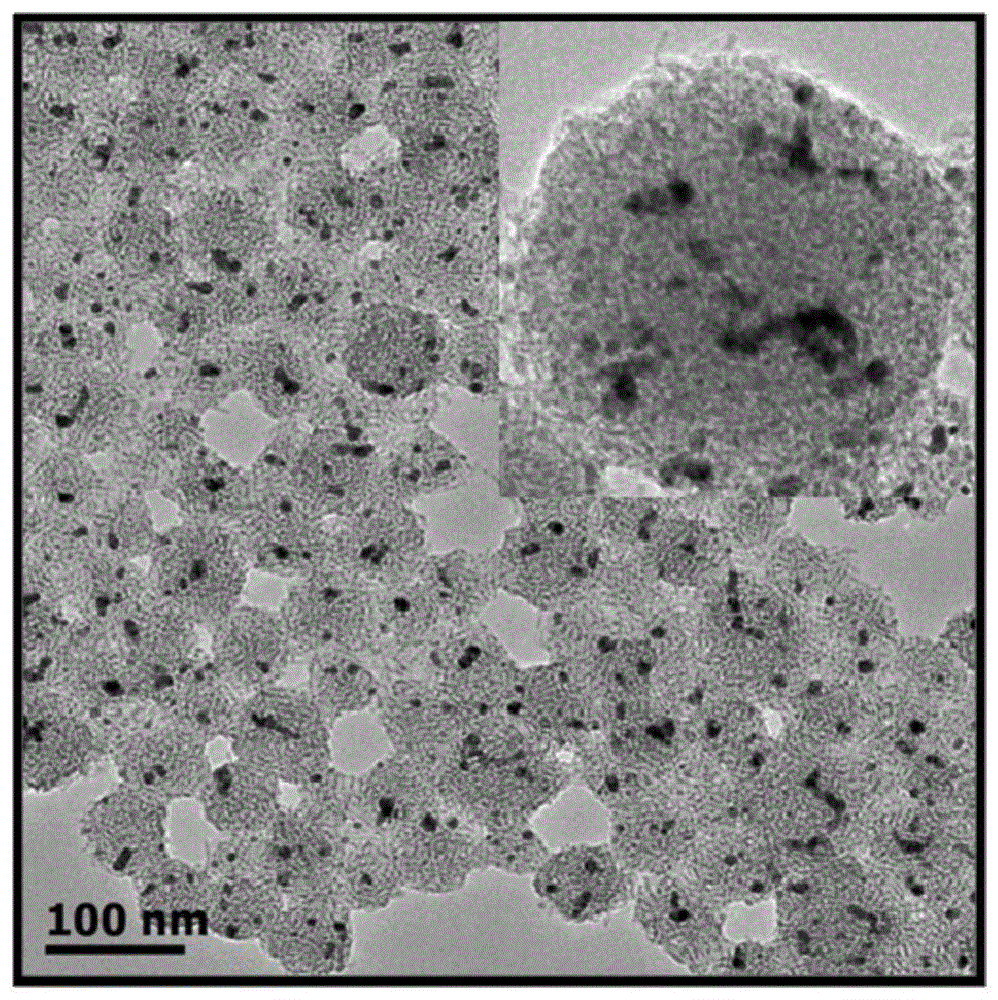

[0040] figure 1 For the obtained silica-filled Au / CdSe@SiO 2 Electron micrographs of nanocluster composites, it can be seen...

Embodiment 2

[0042] Repeat embodiment 1, its difference only is that TiO 2 Nanocrystals added to cyclohexane, TiO 2 The particle size of the nanocrystal is 10nm, and the concentration in the cyclohexane dispersion is 1mg / ml, and the silica-filled Au / CdSe / TiO can be obtained 2 @SiO 2 nanocluster composites.

[0043] The prepared silica-filled Au / CdSe / TiO 2 @SiO 2 Nanocluster composites were characterized by transmission electron microscopy, figure 2 For the obtained silica-filled Au / CdSe / TiO 2 @SiO 2 Electron micrographs of nanocluster composites, it can be seen that Au / CdSe / TiO 2 @SiO 2 Nanocluster composites made of SiO 2 , Au nanocrystals, CdSe nanocrystals and TiO 2 Nanocrystalline composition, SiO 2 Filled throughout Au / CdSe / TiO 2 clusters, and the Au / CdSe / TiO 2 The clusters are completely covered. Au / CdSe / TiO 2 @SiO 2 The size of the nanocluster composite is about 100nm.

Embodiment 3

[0045] Repeat Example 1, the only difference is that the amount of TEOS added is 50ul, Au / CdSe@SiO can still be obtained 2 nanocluster composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com