Preparation method of a defect-enhanced tungsten-doped carbon nitride photocatalyst

A carbon nitride light and tungsten doping technology, applied in the field of photocatalytic materials, can solve the problems of limiting the performance of photocatalytic water splitting for hydrogen production, low utilization rate, inability to effectively separate, etc., and achieve good photocatalytic water splitting to produce hydrogen. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

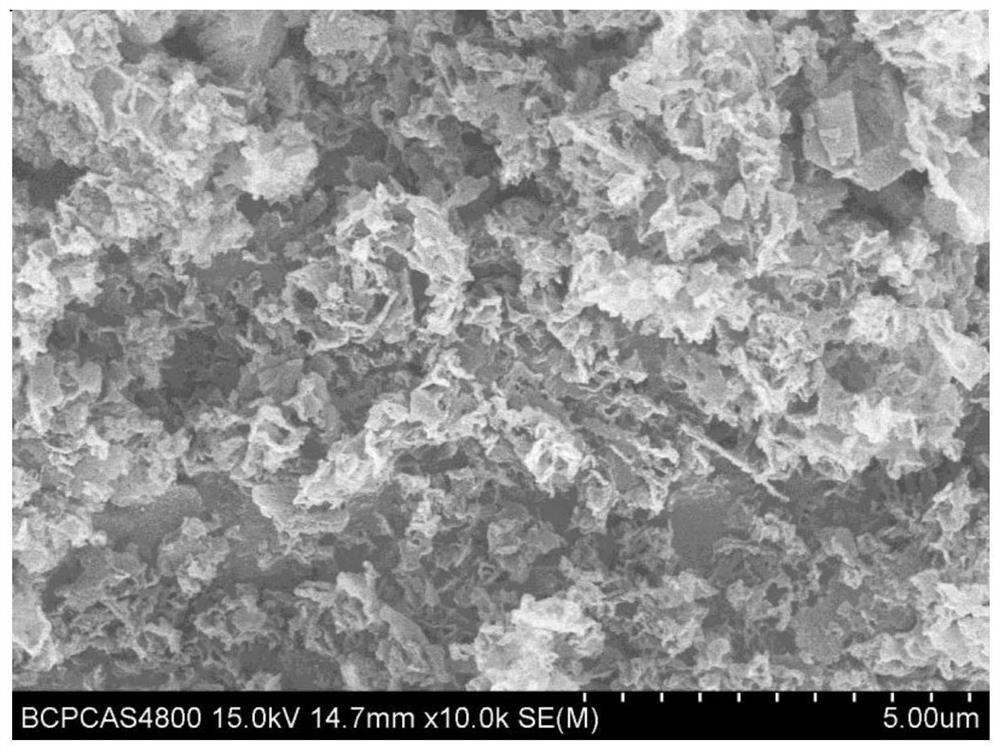

Embodiment 1

[0022] Take 5.4g of melamine and 0.5% doping amount of ammonium metatungstate and place it in a rotary evaporator, put in a magnet, and add 200mL of water. Stir for 30min. Then take out the magnet, install it on a rotary evaporation drying device, use circulating cooling to lower the temperature, and vacuum dry to remove deionized water. Put the dried mixture in a crucible, wrap the crucible tightly with aluminum foil, place it in a muffle furnace and calcinate at 550°C in an air atmosphere, with a heating rate of 5°C / min, keep it warm for 4 hours and then cool it naturally. The obtained powder is tungsten Doped carbon nitride material. Then put it in the tube furnace, check the airtightness of the tube furnace, feed hydrogen, and control the flow rate to 50mL / min. Calcined at 450°C in a hydrogen atmosphere with a heating rate of 5°C / min, held for 1h, and then cooled naturally to obtain a defect-enhanced tungsten-doped carbon nitride photocatalyst.

Embodiment 2

[0024] Take 5.4g of melamine and 0.5% doping amount of ammonium metatungstate and place it in a rotary evaporator, put in a magnet, and add 200mL of water. Stir for 30min. Then take out the magnet, install it on a rotary evaporation drying device, use circulating cooling to lower the temperature, and vacuum dry to remove deionized water. Put the dried mixture in a crucible, wrap the crucible tightly with aluminum foil, place it in a muffle furnace and calcinate at 550°C in an air atmosphere, with a heating rate of 5°C / min, keep it warm for 4 hours and then cool it naturally. The obtained powder is tungsten Doped carbon nitride material. Then put it in a tube furnace, check the airtightness of the tube furnace, feed argon, and control the flow rate to 30mL / min. Calcined at 500°C in a hydrogen atmosphere with a heating rate of 5°C / min, held for 2h, and then cooled naturally to obtain a defect-enhanced tungsten-doped carbon nitride photocatalyst.

Embodiment 3

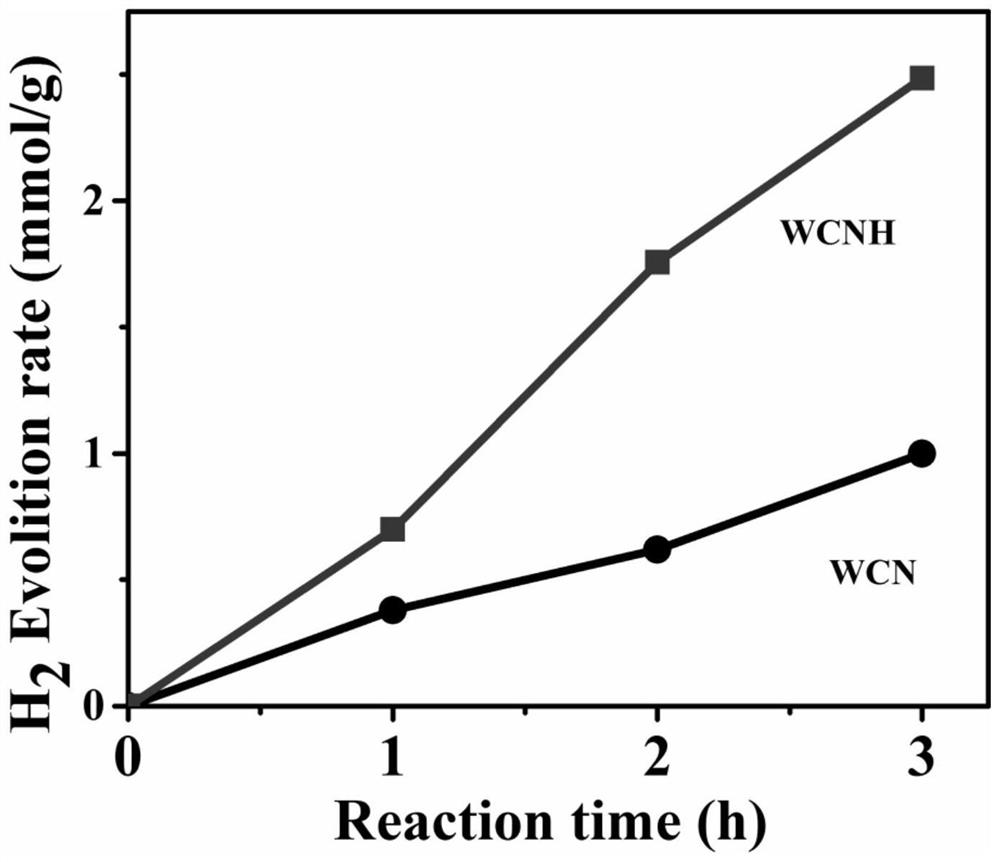

[0026] Take 5.4g of melamine and 0.5% doping amount of ammonium metatungstate and place it in a rotary evaporator, put in a magnet, and add 200mL of water. Stir for 30min. Then take out the magnet, install it on a rotary evaporation drying device, use circulating cooling to lower the temperature, and vacuum dry to remove deionized water. Put the dried mixture in a crucible, wrap the crucible tightly with aluminum foil, place it in a muffle furnace and calcinate at 550°C in an air atmosphere, with a heating rate of 5°C / min, keep it warm for 4 hours and then cool it naturally. The obtained powder is tungsten Doped carbon nitride material, named WCN. It was then placed in a crucible, calcined at 520°C in a hydrogen atmosphere, with a heating rate of 5°C / min, kept for 3h, and then naturally cooled to obtain a defect-enhanced tungsten-doped carbon nitride photocatalyst WCNH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com