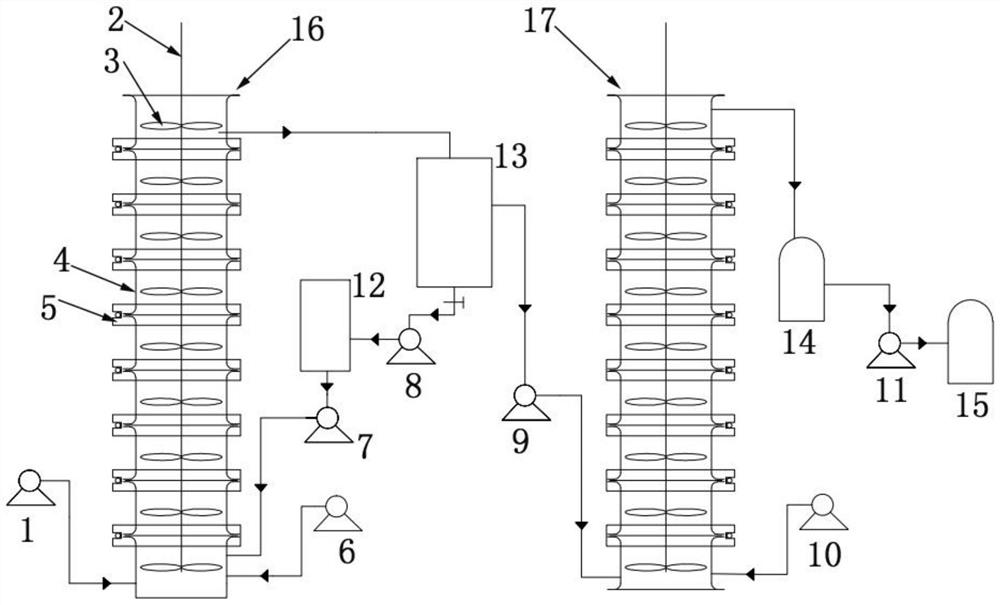

Method and device for continuously preparing biodiesel by connecting multiple towers in series

A biodiesel and product technology, applied in separation methods, biofuels, chemical instruments and methods, etc., can solve problems such as few research reports, and achieve the effects of shortened reaction time, simple assembly, and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of soybean oil methyl ester comprises the following steps:

[0044] Both stirred reaction towers are heated in a super constant temperature water bath at 60°C. Take soybean oil and preheat it to 60°C with a water bath. Mix methanol and KOH at a mass ratio of 300:14, and preheat the resulting methanol-KOH solution to 60°C with a water bath.

[0045] 1) In the first-stage stirring reaction tower, soybean oil and methanol-KOH solution are fed at the same time, the feeding rate of soybean oil is 56.6ml / min, and the feeding rate of methanol-KOH solution is 8.4ml / min. While feeding, turn on the external motor to drive the stirring shaft and the stirring blades to rotate at a speed of 500r / min. Stir and mix the reaction for about 10 minutes, the top of the tower starts to discharge, and the feed liquid enters the static separation tank to stand and stratify. The yield of soybean oil methyl ester is about 83%.

[0046] 2) After reacting for 30 minutes accord...

Embodiment 2

[0051] The preparation of methyl linoleate comprises the following steps:

[0052] Both stirred reaction towers are heated in a super constant temperature water bath at 60°C. Take linoleic acid triglyceride and preheat it to 60°C with a water bath. Mix methanol and KOH at a mass ratio of 20:1, and preheat the resulting methanol-KOH solution to 60°C with a water bath.

[0053] 1) In the first-stage stirring reaction tower, triglyceride linoleate and methanol-KOH solution are fed at the same time, the feed rate of triglyceride linoleate is 59.1ml / min, and the feed rate of methanol-KOH solution is 7.3ml / min . While feeding, turn on the external motor to drive the stirring shaft and the stirring blades to rotate at a speed of 500r / min. Stir and mix for about 9.8 minutes, the top of the tower starts to discharge the material, and the material liquid enters the static separation tank to stand and stratify. The crude glycerol in the static separation tank is not refluxed into the...

Embodiment 3

[0059] The preparation of methyl palmitate comprises the following steps:

[0060] Both stirred reaction towers are heated in a super constant temperature water bath at 60°C. Take industrial palm oil and preheat it to 60°C with a water bath. Mix methanol and KOH at a mass ratio of 350:14, and preheat the resulting methanol-KOH solution to 60°C with a water bath.

[0061] 1) In the first-stage stirring reaction tower, industrial palm oil and methanol-KOH solution are fed at the same time, the feed rate of industrial palm oil is 55.6ml / min, and the feed rate of methanol-KOH solution is 10.8ml / min. While feeding, turn on the external motor to drive the stirring shaft and the stirring blades to rotate at a speed of 500r / min. Stir, mix and react for about 10 minutes, the top of the tower starts to discharge, and the feed liquid enters the static separation tank to stand and stratify. The crude glycerol in the static separation tank is not refluxed into the first-stage stirring rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com