Energy storage polymer dielectric and preparation method and application thereof

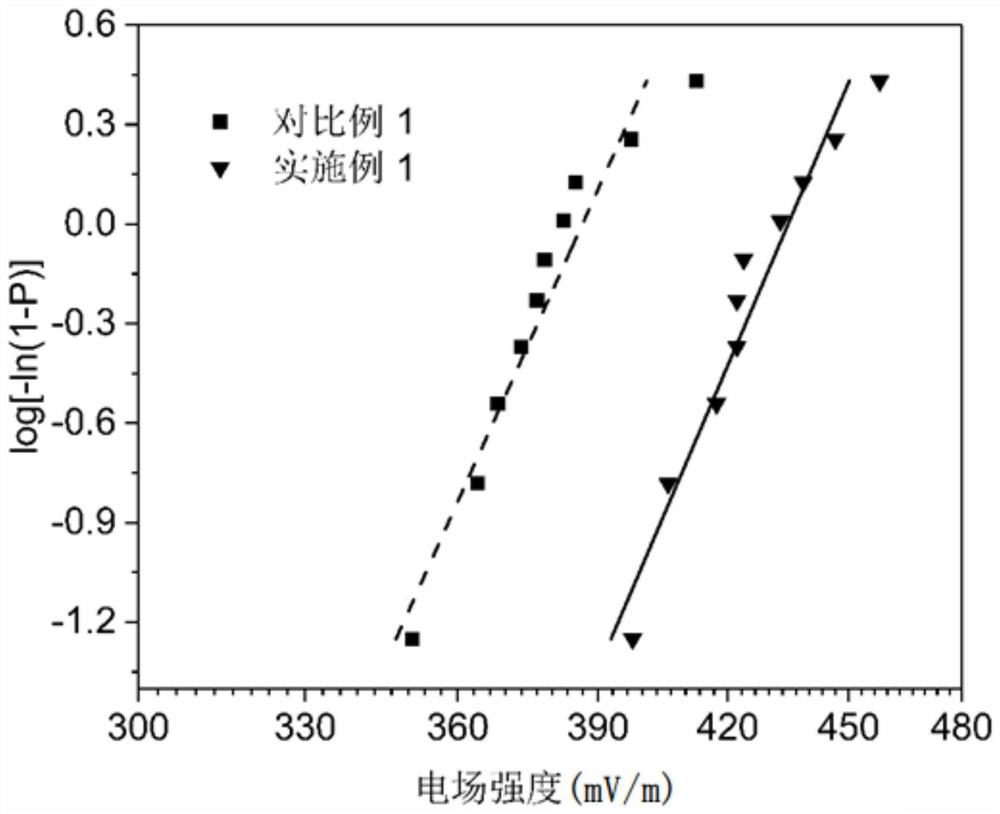

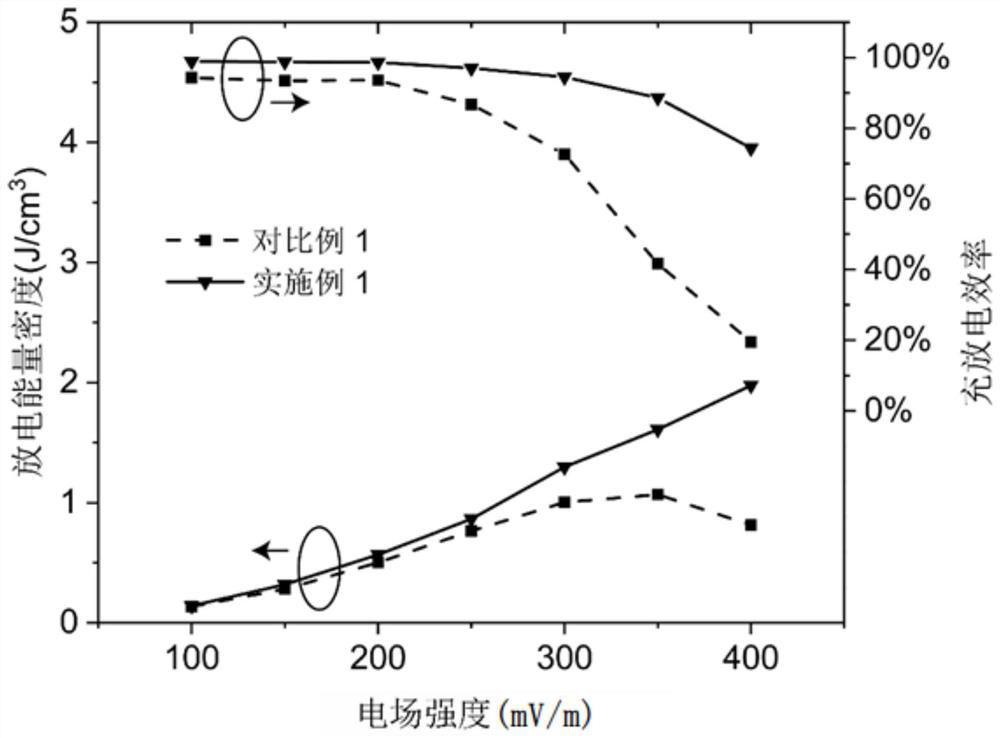

A polymer and dielectric technology, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, etc., can solve the problems of efficiency drop, loss increase, etc., and achieve the effect of small temperature rise, dense uniformity, and easy control of preparation parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Using polyetherimide dielectric film as the base material (purchased from Polyk, USA), ultrasonically removed impurities and dirt on the surface in alcohol; company) for magnetron sputtering with a distance of 10 cm between target and substrate in Ar and O 2 (40:4) In the mixed atmosphere, magnetron sputtering was used to deposit Al2O3 on the surface of the film, and the working pressure was 0.5Pa; the sputtering time was adjusted according to the thickness, and the sputtering thickness was 150nm; the sputtering power was 200W . Metal oxide thin films were deposited on both sides of the original polymer dielectric base film to obtain energy storage polymer dielectric samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com