Automatic shearing device for sewing residual threads and gas transmission structure thereof

A technology of cutting device and residual thread, which is applied in the sewing machine to cut off the thread mechanism, sewing equipment, sewing machine components, etc. It can solve the problem of low production efficiency, difficulty in controlling and ensuring quality stability, and inability to effectively reduce labor costs. and other issues, to achieve the effect of saving setting costs, economical use efficiency, and short wire ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The detailed description and technical content of the embodiments of the present application are described below with the accompanying drawings. However, the drawings are only provided for reference and illustration, and are not used to limit the embodiments of the present application.

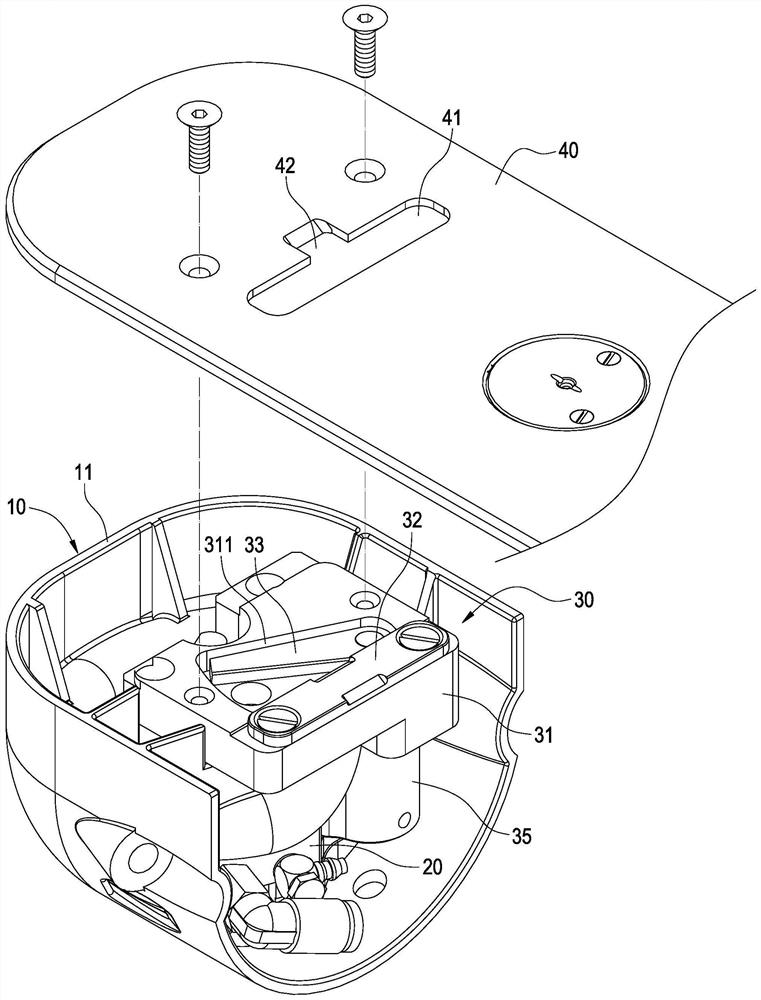

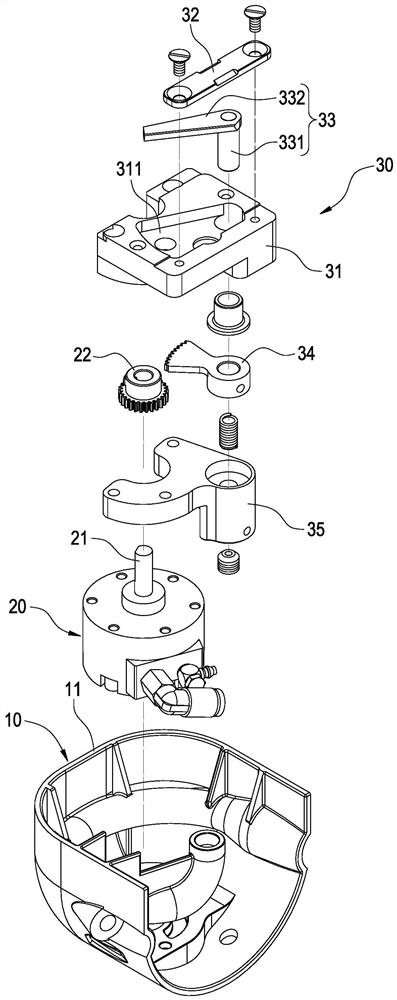

[0055] see Figure 1 to Figure 4 As shown, the embodiment of the present application provides an automatic cutting device for sewing residual thread, which mainly includes an air delivery structure 10 , an actuator 20 and a cutter structure 30 .

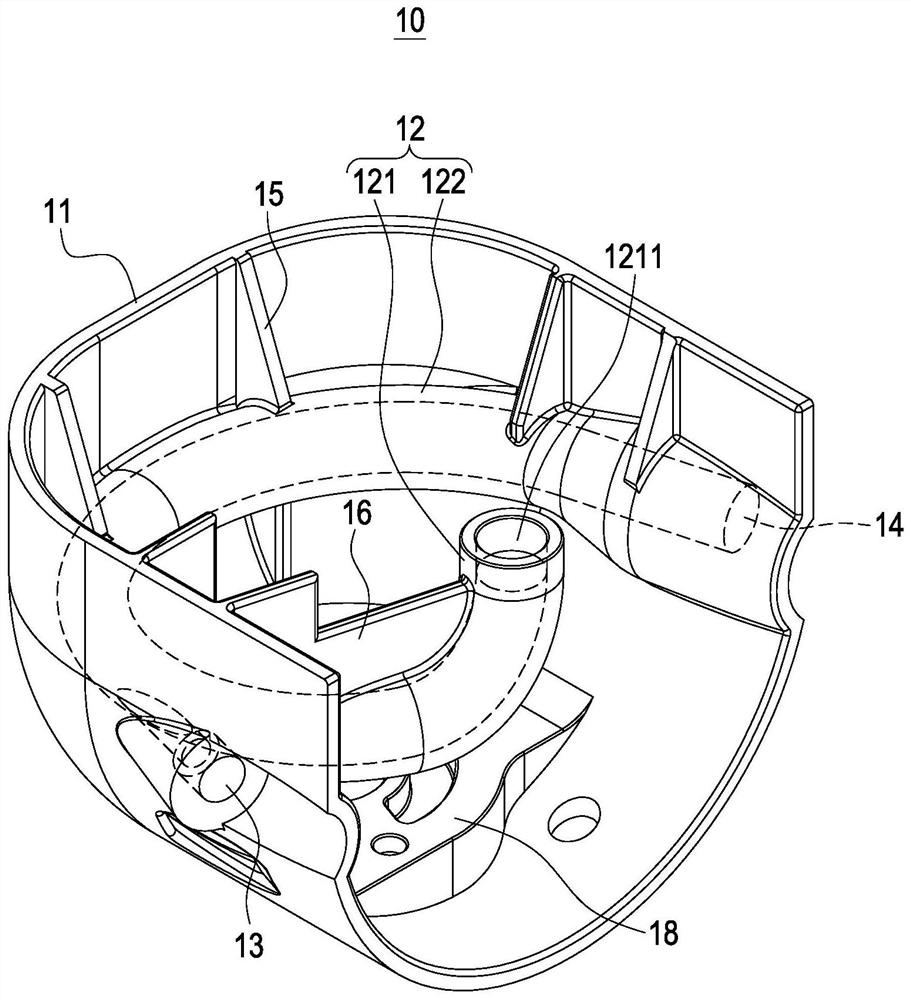

[0056] like image 3 and Figure 4 As shown, the gas transmission structure 10 includes a shell cover 11, which is roughly a U-shaped three-dimensional structure, and an air delivery pipe 12 is arranged inside the shell cover 11. The air delivery pipe 12 mainly includes a suction section 121 and a delivery section 122 connected to the suction section 121. , and at the two side positions of the shell cover 11, there are air intake holes 13 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com