Drying device for art media printing

A drying device and media technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of insufficient drying, unable to dry printed materials in time, and high concentration of residual solvents, etc., to achieve the effect of avoiding insufficient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

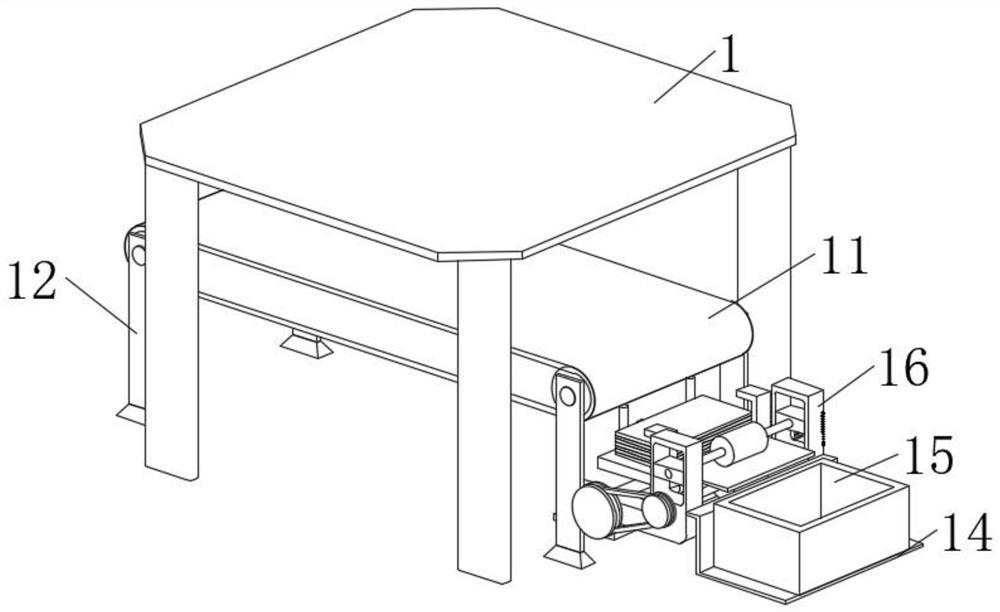

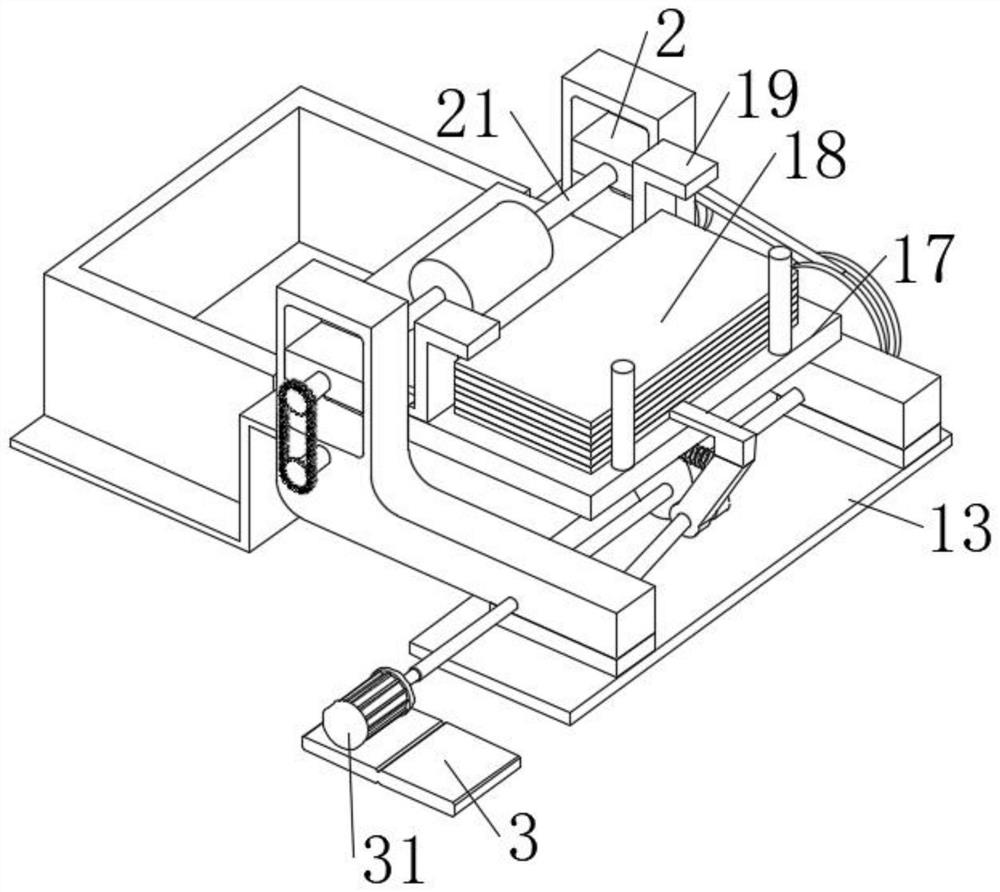

[0026] Example: Figure 1-7 As shown, the present invention provides an artistic media printing drying device including a support frame 1, and a belt 11 is provided below, and both ends of the transmission belt 11 are connected to the leg 12, two of them. A connecting plate 13 is connected between the support legs 12, and the surface of the connecting plate 13 is configured with two connecting blocks 16, and the connecting block 16 is connected between the dryer 17, the lumen of the connecting block 16. Both are connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com