Method for modeling and controlling tobacco moisture regaining water adding flow based on historical production data

A technology of adding water flow and production data, which is applied in the field of controlling tobacco moisture and water flow based on historical production data modeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

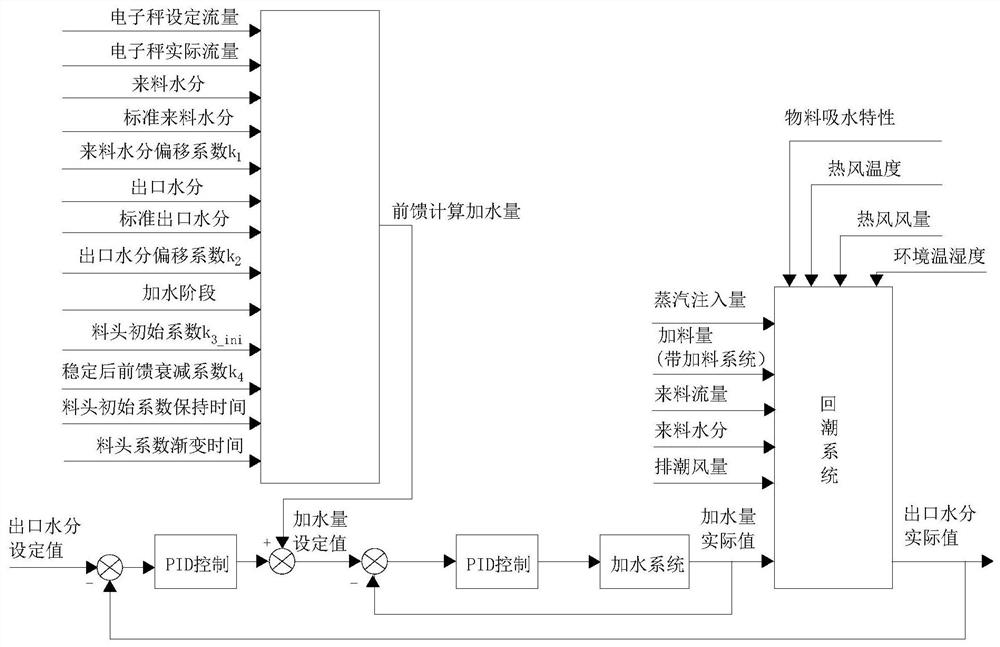

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

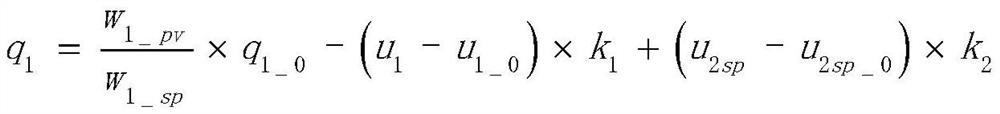

[0105] A method based on historical production data modeling to control the water flow rate of tobacco rehydration. When the tobacco rehydration process is at the head stage, the actual water flow rate q of tobacco rehydration is controlled at the head stage _head The following formula 2 is used:

[0106] q _head =q 1_head =q 1 ×k 3

[0107] In the above formula, q _head is the actual flow rate of water added in the stage of tobacco moisture regain at the head stage, q 1_head Tobacco rehydration and water flow rate calculated for the feed-forward stage of the material head stage, k 3 is the coefficient of variation of the material head.

[0108] In this embodiment, the coefficient of variation k of material head 3 The initial value of k 3_ini , k 3_ini The general value range is 0.8~1.2, k 3 The cutoff value for is 1.0. k 3 The changing law of is to keep the initial value first, then gradually change, and finally keep the termination value, because the performance...

Embodiment 2

[0112] This embodiment is based on the first embodiment, when the tobacco moisture regain process is in the transition process stage, the transition process stage controls the actual water flow q of tobacco moisture regain _tran The following formula 3 is used:

[0113] q _tran =q 1_tran +q 2 =q 1 +q 2

[0114] In the above formula, q _tran is the actual flow rate of water added to the tobacco moisture in the transition process stage, q 1_tran Tobacco remoisturization and water flow rate obtained by feed-forward calculation for the transition process phase.

[0115] In this embodiment, according to the outlet moisture setting value u 2sp and the actual outlet moisture u 2 The deviation of the PID closed-loop feedback operation is performed to obtain the feedback adjustment offset q 2 , with q 1_tran +q 2 As the actual water flow q _tran To control the tobacco remoisture process.

[0116] In this embodiment, the coefficient of variation k of material head 3 After...

Embodiment 3

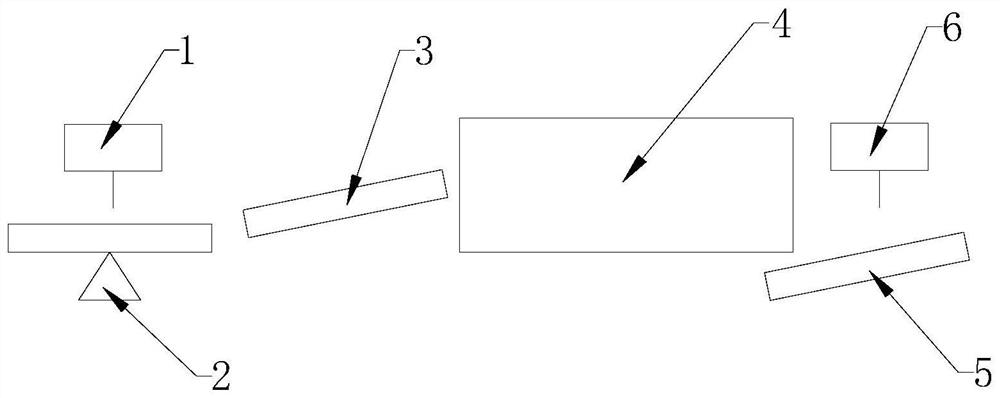

[0119] In this embodiment, on the basis of Embodiment 2, within the time t1, the rehydrated material is output through the discharge vibration tank 5, and the actual outlet moisture u can be detected by the outlet moisture meter 6. 2 , the actual outlet moisture u 2 Close to the outlet moisture set value u 2spAnd the outlet moisture setting value u 2sp and the actual outlet moisture u 2 The deviation is less than 0.35%, indicating that due to the difference in actual production conditions, the flow rate q of tobacco moisture plus water obtained by feed-forward calculation 1_tran Too high, it is necessary to start the feedback adjustment offset q in advance 2 , to eliminate modeling errors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com